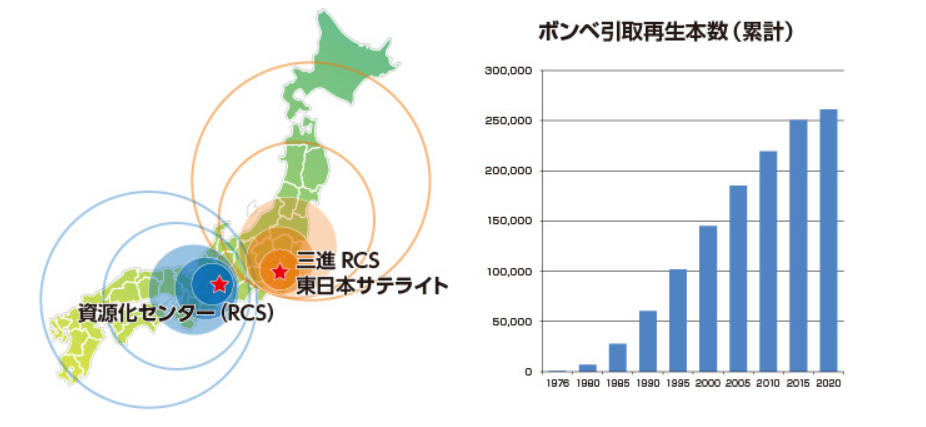

Our Resource Center, established at our Inuyama Plant in 1976 to recover and reuse metals from plating process wastewater, collects and regenerates over 6,000 cylinder-type ion exchange towers annually for customers nationwide. By the end of March 2016, it had regenerated more than 250,000 towers.

Furthermore, we established the Sanshin RCS East Japan Satellite in Tokyo in 2016 to improve the efficiency of regenerating ion exchange towers.

Sanshin

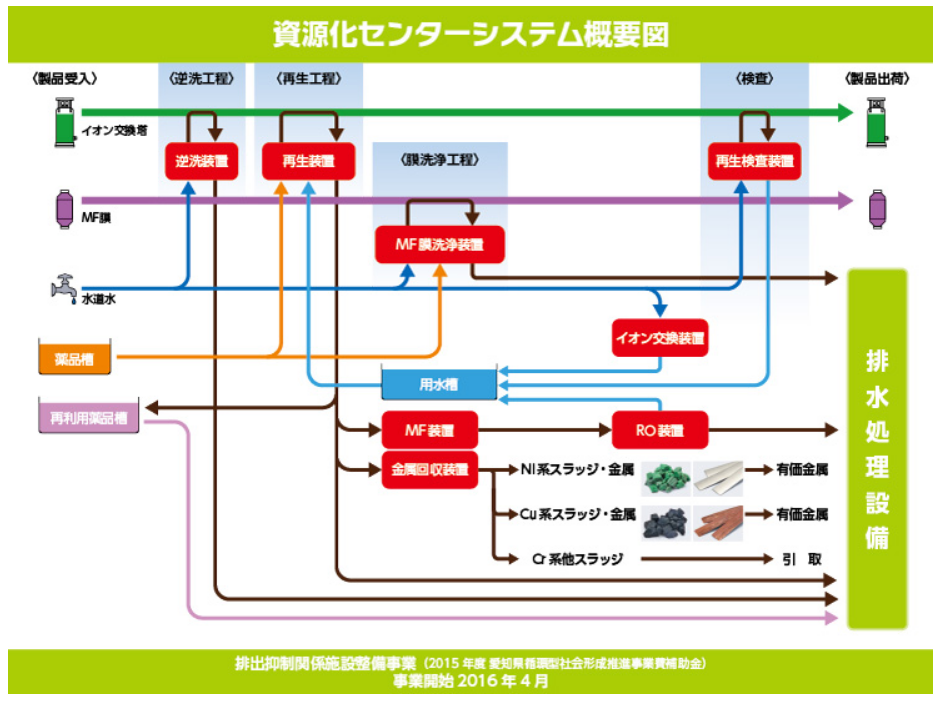

Sanshin Resource Center System regeneration of ion exchange resin

Manufacturer: Sanshin Manufacturing Co., Ltd

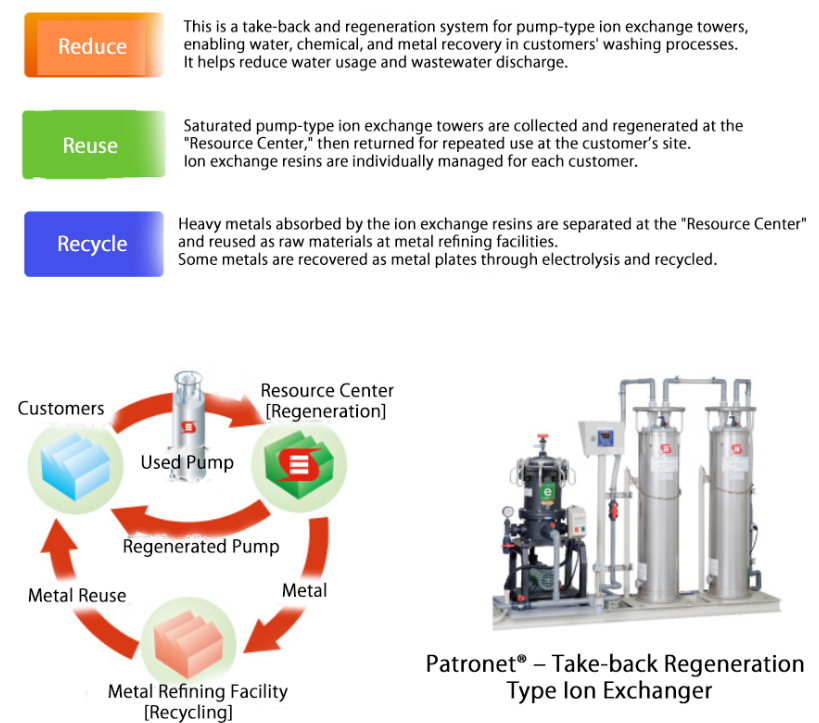

Sanshin Seisakusho’s resource recovery center system is a system that realizes the recycling of resources by collecting resources (metals, chemicals, water, etc.) that would otherwise be discarded in individual processes at a “resource recovery center” and carrying out centralized sorting and recovery processing.

Resource Center System Performance

Brief history of the Resource Center System

- 1971.8

- The research topic “Industrialization Tests on Plating Wastewater Treatment Combined with Reuse of Chemicals and Water” was designated as an important technology development topic by the Ministry of International Trade and Industry for fiscal 1971.

- 1976.4

- Established a resource recovery center at the Inuyama Factory. Started sales of cylinder-type ion exchange machines (Patrone i®) and began a recycling business.

- 1983.5

- Received the Tokai Chemical Industry Association Award.

- 1988.5

- Received the Tokai Chemical Industry Association Award.

- 2007.2

- Received the Aichi Environmental Award, Silver Prize.

- 2010.4

- The company was recognized as a pioneering and effective recycling business by Aichi Prefecture in fiscal 2009, and has since launched an even more sophisticated resource recovery system business.

- 2010. 7

- Certified as an Aichi Eco-Town facility.

- 2012.11

- Received the Japan Environmental Management Association for Industry Chairman’s Award at the Resource Recycling Technology and System Awards.

- 2016.4

- Received certification from Aichi Prefecture for the FY2015 Leading and Effective Emission Reduction Facility Development Project, and carried out construction to upgrade the Resource Recycling Center and launch a resource recovery system business with the new equipment.

- 2016.5

- Selected as one of the “300 SMEs and small businesses that are thriving” by the Ministry of Economy, Trade and Industry.

- 2016.11

- Sanshin RCS East Japan Satellite opens in Tokyo as a new collection and regeneration base for ion exchange towers.

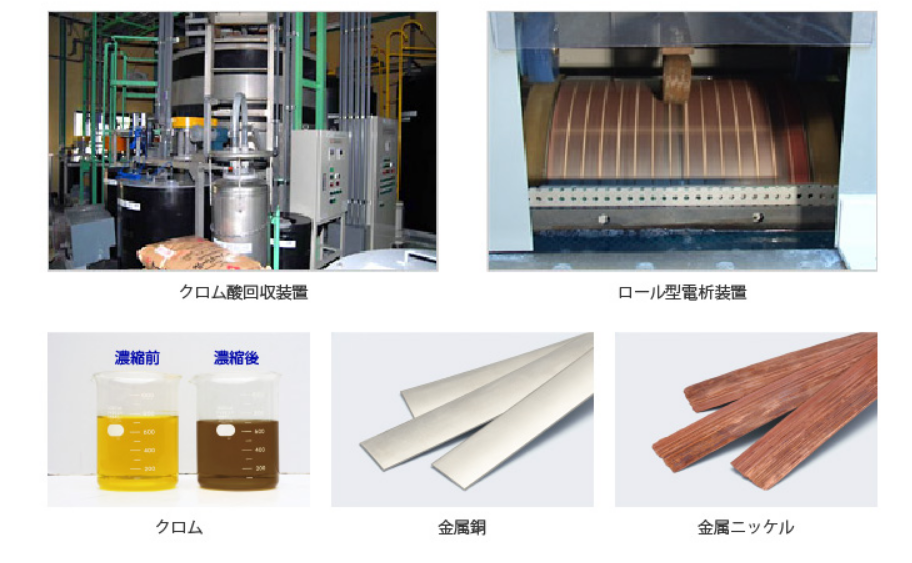

At the highly functional Resource Recycling Center, the chromate recovery equipment concentrates and refines the chromate eluent to the recycling standard value.The copper and nickel that were previously turned into sludge and recycled at the Yamamoto smelter are now recovered as metal sheets using roll-type electrodeposition equipment, improving resource recovery efficiency and reducing waste.

In addition, we were able to reduce the overall amount of chemicals used by reusing some of the waste acid and alkali from the regenerated chemicals as wastewater treatment chemicals.

Furthermore, a portion of the wastewater is desalinated and reused, reducing water usage.

Related Products

-

Sanshin Econoselfy® On-site regenerative ion exchange equipment

-

Sanshin OH Filter Press Dehydration Filtration Equipment

-

Sanshin Patrone ie Cartridge type small ion exchanger

-

Sanshin Patrone i Cylinder-type ion exchanger

-

Sanshin Pure water production equipment Econovac pure water production unit

-

Sanshin B-type Auto Sand Small rapid sand filter