BINZEL JAPAN Ltd

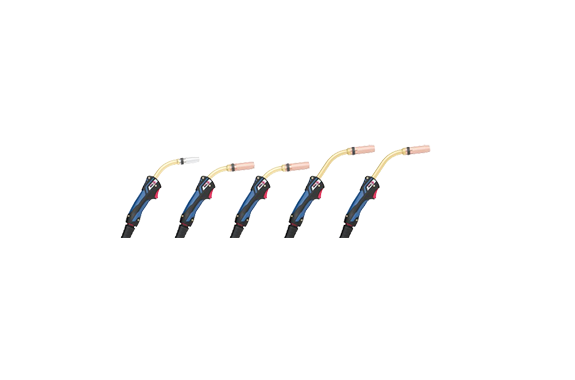

Binzel Japan MIG, MAG Welding Torch MB EVO PRO

Manufacturer: BINZEL JAPAN Ltd

Model: MB EVO PRO

A New Standard

The MB EVO PRO torch series represents a whole new concept in welding torch design, shape and function. The unique ergonomics, developed through trial and error, allow the welder to “be one” with the torch, giving you great control. The trigger position, trigger design and ball joint ensure optimal balance and comfort at all welding angles.

MIG/MAG welding is a tough process. Not only is it lighter and more sleek, the new MB EVO PRO torch line sets a new benchmark in durability. The new design features an improved space inside the handle for better fitting and easier servicing. Technology for welding professionals – that’s MB EVO PRO. The MB EVO PRO air-cooled welding torch features the “BIKOX ®

LW” lightweight cable assembly , scientifically proven to improve handling and reduce user fatigue at all welding angles . Improved handling and reduced physical strain have a significant impact on the quality of the weld seam.

Proven “MB” consumables concept – long-lasting and economical

Genuine two-component handle – sturdy and ergonomic

Optimal trigger position and tapered handle design – Supports handling as you wish

Unique air-cooled torch internal design – provides grip cooling and maximum durability

Lightweight BIKOX ® (LW) cable assemblies – offering 34% weight reduction

Robust and optimal central connector

The MB EVO PRO water-cooled torch has been further refined with a new cooling concept and a combination of carefully selected components. Improved front-end cooling allows for longer consumable life, longer maintenance intervals and higher power welding.

Top quality “MB” consumables combined with optimal torch cooling – optimized product life

Genuine two-component handle – sturdy and ergonomic

Optimal trigger position and tapered handle design – Supports handling as you wish

Simple internal structure provides ample space for maintenance – simplifying repair and maintenance

High-performance hose with special protective material – flexibility and comfort on the job

Robust and optimized central connector and protected hose guide

Air-cooled

Technical data (EN 60 974-7):

| kinds: | MB EVO PRO 15 | MB EVO PRO 24 | MB EVO PRO 25 | MB EVO PRO 26 | MB EVO PRO 36 |

| specification | |||||

| C02: | 180A | 250A | 230A | 270A | 320A |

| Gas mixture M21*: | 150A | 220A | 200A | 240A | 290A |

| Duty Cycle(%): | 60 | 60 | 60 | 60 | 60 |

| Wire diameter 0 (mm): | 0.6-1.0 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 |

Data according to DIN EN ISO 14175

Data according to DIN EN ISO 14175

The duty cycle is calculated based on the VDE standard voltage/current index (U=14+0.05xl) formula. Pulse welding reduces the duty cycle by 35%.

Water-cooled

Technical data (EN 60 974-7):

| kinds: | MB EVO PRO 240 D | MB EVO PRO 401 | MB EVO PRO 401 D | MB EVO PRO 501 | MB EVO PRO 501 D |

| specification | |||||

| C02: | 325A | 475 A | 450A | 575 A | 550A |

| Gas mixture M21*: | 300A | 425 A | 400A | 525A | 500A |

| Duty Cycle(%): | 100 | 100 | 100 | 100 | 100 |

| Wire diameter 0 (mm): | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 1.0-1.6 | 1.0 -1.6 |

Data according to DIN EN ISO 14175

Data according to DIN EN ISO 14175

The duty cycle is calculated based on the VDE standard voltage/current index (U=14+0.05xl) formula. Pulse welding reduces the duty cycle by 35%.

A water circulation cooling capacity of approximately 800 W is recommended, and a minimum of a 4 minute cooling cycle should be allowed between welding operations to protect the cable assembly from overheating.