BINZEL JAPAN Ltd

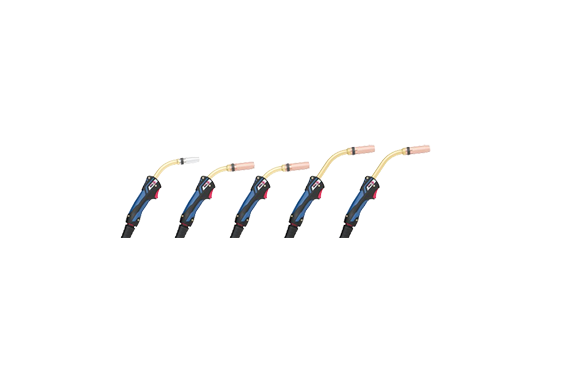

Binzel Japan MIG/MAG Welding Torch MB GRIP

Manufacturer: BINZEL JAPAN Ltd

Model: MB GRIP

Superior ergonomics and flexibility

The MIG/MAG torch series “MB GRIP” is an unrivaled premium solution for both air-cooled and water-cooled torches. It combines innovative technology with optimized ergonomic qualities to ensure stable operation in any application.

The “GRIP” insert and the ball joint in the handle ensure high grip security and handling. This torch is meticulously designed for comfortable and precise work.

Features:

Short ergonomic handle with “GRIP” insert for easy access

Soft material handle and thumb rest – for optimal handling even in the toughest conditions

Short ball joint with optimized range of motion for precise handling

Optimized torch cooling for longer life

Bikox ® R Air-Cooled Torch – High flexibility in low temperature environments, high UV resistance, and greatly improved heat resistance and elongation

ABICOR BINZEL’s central adapter system reduces torch change times

Air-cooled

Technical data (EN 60 974-7):

| type: | MB GRIP 15 AK | MB GRIP 24 KD | MB GRIP 25 AK | MB GRIP 26 KD | MB GRIP 36 KD |

| specification | |||||

| CO2 : | 180A | 250A | 230A | 270A | 320A |

| Gas mixture M21*: | 150A | 220A | 200A | 240A | 290A |

| Duty Cycle(%): | 60 | 60 | 60 | 60 | 60 |

| Usable wire diameter Ø (mm): | 0.6 – 1.0 | 0.8 – 1.2 | 0.8 – 1.2 | 0.8 – 1.2 | 0.8 – 1.2 |

* Data according to DIN EN ISO 14175

* Data according to DIN EN ISO 14175

The duty cycle is calculated based on the VDE standard voltage/current index (U=14+0.05xl) formula. Pulse welding reduces the duty cycle by 35%.

Water-cooled

Technical data (EN 60 974-7):

| type: | MB GRIP 240 D | MB GRIP 401 | MB GRIP 401 D | MB GRIP 501 | MB GRIP 501 D |

| specification | |||||

| CO2 : | 300A | 450A | 400A | 550A | 500A |

| Gas mixture M21*: | 270A | 400A | 350A | 500A | 450A |

| Duty Cycle(%): | 100 | 100 | 100 | 100 | 100 |

| Usable wire diameter Ø (mm): | 0.8 – 1.2 | 0.8 – 1.2 | 0.8 – 1.2 | 1.0 – 1.6 | 1.0 – 1.6 |

* Data according to DIN EN ISO 14175

* Data according to DIN EN ISO 14175

The duty cycle is calculated based on the VDE standard voltage/current index (U=14+0.05xl) formula. Pulse welding reduces the duty cycle by 35%.

A water circulation cooling capacity of approximately 800W is recommended, and a minimum of 4 minutes cooling cycle should be allowed between welding operations to protect the cable assembly from overheating (10 minutes rating, 60% duty cycle).