BINZEL JAPAN Ltd

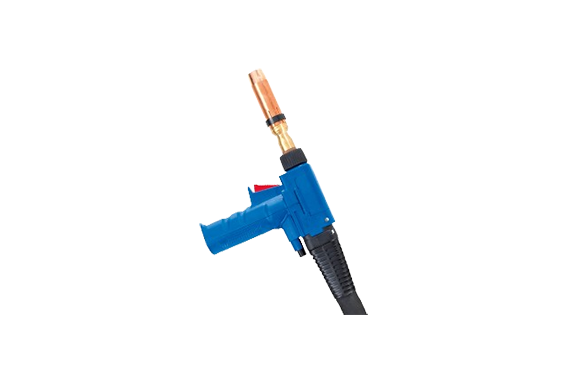

Binzel Japan Welding Torch Push-Pull Plus

Manufacturer: BINZEL JAPAN Ltd

Model: Push,Pull Plus

Optimal wire feed

Short Summary:

The Push-Pull Plus welding torch series features a high-power pull motor with precise speed control and adjustable feeding roller for consistent wire feeding—even with long cables. It offers an ergonomic, quickly changeable torch neck (straight or 45°) with a 360° rotatable interface, supports up to 400A in both air and water cooling, and uses the same consumables as the MB series to reduce inventory. Its optimized cooling and durable design ensure a long product life.

Air Cooled

Technical data according to EN 60 974-7:

| type: | Push-Pull Plus 36D |

| specification | |

| CO2 : | 300A |

| Gas mixture M21*: | 270A |

| Duty Cycle(%): | 60 |

| Usable wire diameter-Ø (mm): | 0.8 – 1.2 |

* Data according to DIN EN ISO 14175

Engineers calculate the duty cycle using the VDE standard voltage/current index (U = 14 + 0.05xl) formula. Pulse welding reduces the duty cycle by 35%.

Water-cooled

Technical data according to EN 60 974-7:

| type: | Push-Pull Plus 401 D |

| specification | |

| CO2 : | 400A |

| Gas mixture M21*: | 350A |

| Duty Cycle(%): | 100 |

| Usable wire diameter-Ø (mm): | 0.8 – 1.2 |

* Data according to DIN EN ISO 14175

The duty cycle is calculated based on the VDE standard voltage/current index (U=14+0.05xl) formula. Pulse welding reduces the duty cycle by 35%.

A water circulation cooling capacity of approximately 800W is recommended, and a minimum of 4 minutes cooling cycle should be allowed between welding operations to protect the cable assembly from overheating (10 minutes rating, 60% duty cycle).