BINZEL JAPAN Ltd

Binzel Japan Contact Tip Or Contact Tube For MIG/MAG Welding Torch

Manufacturer: BINZEL JAPAN Ltd

Contact tips (sometimes also referred to as contact tubes, power contact tubes or contact nozzles) are consumables used in MIG/MAG welding and are mass-produced today. As a result, there is a wide variety of welding accessories and attachments on the market. All original contact tips from ABICOR BINZEL are stamped with the BINZEL mark and are of extremely high quality, fulfilling all the requirements of the welding process.

The contact tip is undoubtedly the smallest component, but it is the most important attachment required for MAG welding. Contact tips are used in semi-automatic, automatic or robotic welding torches. The material and processing quality have a great influence on the entire welding process and its service life, that is to say, on the machine uptime or the availability of the welding torch. It is therefore very important to pay attention to the quality of the contact tip during the selection process. ABICOR BINZEL contact tips meet the requirements of the respective welding process and guarantee a high durability and long machine uptime.

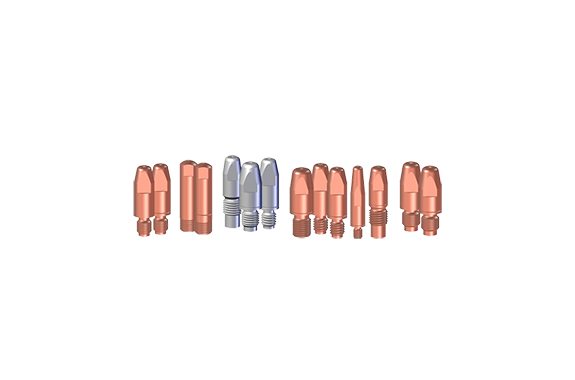

Contact Tip Type

Depending on the contact tip used, several kilometers of wire pass through this small attachment per day. It is therefore all the more important to use high-quality contact tips that are suitable for the welding application and the torch. Welding torch manufacturers recommend the best contact tip for your torch and welding process in their product catalogue. They are available in thread connection sizes M6, M8, M10 and larger. The overall shape and the exact positioning of the central hole according to the wire diameter and material of the contact tip are important. ABICOR BINZEL uses a patented manufacturing process for precise drilling. A basic rule in welding: the higher the welding power, the larger the contact tip dimensions.

Contact Tips – Materials and Characteristics

In welding, contact tips are used in the following materials: E-Cu (electrolytic copper), CuCrZr (copper-chromium-zirconium), HDS (high durability silver tip, a special variant with an inner core of hard copper, making it very hard, and with a cover of electrolytic copper).

E-Cu contact tip

Manufactured from pure electrolytic copper, the contact tips have a Vickers hardness (HV) of approximately 110-115. The purity of this copper ensures the best electrical current transfer, heat transfer and thermal conductivity. It softens at approximately 260°C, making it suitable for use with low current values.

CuCrZr contact tip

Contact tips made of alloying elements chromium and zirconium are very hard and therefore suitable for high heat loads. Compared to electrolytic copper contact tips, their thermal conductivity is slightly lower, but for many processes this difference is not a major issue. CuCrZr contact tips have a hardness of approximately 168HV and can withstand temperatures up to approximately 500°C.

CuCrZr contact tips are standard contact tips for medium to high currents with low wear and high load resistance, and are primarily used in water-cooled welding applications or robotic welding applications.

HDS contact tip (high durability silver tip)

When CuCrZr contact tips reach their limiting load, HDS contact tips are used. The inner core of HDS contact tips around the tip bore consists of dispersion-hardened copper with mineral materials. As a result of this combination, the core of HDS contact tips is extremely hard and highly heat resistant. In addition, the silver coating reduces spatter adhesion.

HDS contact tips are used in welding applications that require high duty cycles and high power consumption, and are applied to air-cooled welding torches with high current values, such as:

- Flux cored wire

- Shipbuilding and Containers

- Earthmoving machinery

- Welding and cladding overlay methods

ABICOR BINZEL HDS contact tips are ideally suited for robotic automated welding processes as they are able to meet the highest demands of a continuously optimized process.

Contact tip and welding wire

Is there any recommendation for which welding wire should be used with which welding tip? In general, the three types of contact tips (E-Cu, CuCrZr, HDS) can be welded with any wire. However, it is important to know the material and properties.

For example, aluminum wire is a little less conductive than copper-plated wire, so aluminum can be welded better with E-Cu contact tips, which have better current transmission performance. However, aluminum has a high thermal expansion, so when selecting the contact tip, the inner diameter of the tip hole needs to be a little larger.

Welding wire consists of the following materials:

Copper-plated and non-copper-plated carbon steel

Stainless steel alloy

Aluminum alloy

Copper brazing alloys (silicon-based copper alloys, etc.)

Special materials such as nickel and titanium alloys

Cored Wire

Depending on the quality of the wire surface, different welding wires wear differently. Cored wires and non-copper plated wires have a rougher surface and will wear or fray faster. When these wires are used, harder contact tips are used, such as CuCrZr contact tips.