BINZEL JAPAN Ltd

Binzel Japan TIG Welding Fume Extraction Torch For Clean

Manufacturer: BINZEL JAPAN Ltd

Model: TIG

TIG welding generates minimal visible fumes, but invisible toxic fumes can cause health risks like silicosis and respiratory cancer. You must capture and remove these fumes before inhalation or release. ABICOR BINZEL’s xFUME® TIG fume suction torch, in water-cooled and air-cooled versions, captures fumes at the source, protecting the welder.

The xFUME® TIG fume suction torch works best with ABICOR BINZEL’s FES-200 W3 or FEC W3 devices, which use W3 filters to capture fumes from alloy steels with more than 30% nickel and chromium.It is also compatible with non-W3 certified devices, other manufacturers’ models, and other ABICOR BINZEL units.

The xFUME® TIG fume suction torch works best with ABICOR BINZEL’s FES-200 W3 or FEC W3 devices, which use W3 filters to capture fumes from alloy steels with more than 30% nickel and chromium.It is also compatible with non-W3 certified devices, other manufacturers’ models, and other ABICOR BINZEL units.

TIG welding produces gases such as ozone, nitrogen oxides, and harmful compounds like nickel oxide and chromium (VI).

TIG welding produces ozone and nitrogen oxides, with ozone classified as carcinogenic under TRGS905. Ultraviolet light from the welding arc reacts with nitrogen oxides and oxygen to form ozone, particularly when welding aluminum-silicon alloys and pure aluminum. The ultraviolet rays spread outward, affecting distant areas and promoting ozone generation, even with low fumes. Additionally, nickel oxide and chromium (VI) compounds released during stainless steel welding produce harmful gases that can cause cancer. You must capture these gases with W3-rated filters and dispose of them according to local regulations.

Current Laws and Regulations Regarding Welding Fume Suction

In Germany, strict regulations govern the collection of harmful welding fumes to protect workers’ health. The Hazardous Substances Act (GefStoffV) and DIN EN ISO 15012-1 require you to collect and treat dust particles safely. You can return air drawn into fume extraction equipment with W2* or W3** filters to the environment, with limits for alloy and high-alloy steels.TRGS 528 and DGUV regulation 109-002, updated in 2020, revise welding fume inhalation laws, mandating compliance for worker safety.

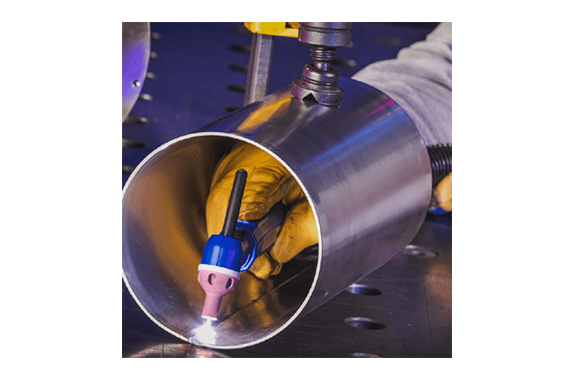

xFUME ® TIG: Fume extraction from fume sources

Companies that employ welders have strict requirements. The demands for a safe working environment require further technological advances. ABICOR BINXEL has developed the xFUME ® TIG fume suction torch as a water-cooled and air-cooled fume suction torch, which is by no means inferior to our fume suction torches for MIG/MAG. It has the same level of performance as the xFUME ® PRO series and xFUME® COMPACT , and is capable of suctioning fumes from the fume source during TIG welding.

Fume suction in TIG welding is less critical than in MIG or MAG welding, as less fume is generated. ABICOR BINZEL’s xFUME® TIG fume suction torches are lightweight and easy to use with mobile fume suction devices that collect and filter harmful particles. Devices with a W3 separation degree can return filtered air to the environment, creating a complete fume suction system. A high-performance vacuum system with high negative pressure and low flow rate is required for effective fume suction. The fumes are captured by the TIG suction nozzle and filtered through a W3 filter, returning clean air to the workspace. Suitable devices include the FES-200 W3 and FEC W3.

More about xFUME ® TIG fume suction torch

For general welding processes, the air-cooled xFUME® TIG 150 is ideal for welding currents up to 105A AC (150A DC) at a duty cycle of 35%, while the water-cooled xFUME® TIG 260 W is ideal for welding stainless steel, aluminum alloys and high alloy materials at a duty cycle of 100% and welding currents up to 180A AC (260A DC). The water-cooled xFUME® TIG 300 W is particularly strong in high amperage AC processes, e.g. when welding aluminum materials.

Of course it can also be used for all other TIG welding processes.

No matter what welding material produces harmful fumes during welding, the xFUME® TIG fume suction torch is a safe and reliable tool for welders.

The xFUME® TIG fume suction torch features a patented nozzle with protection and suction functions, and highly durable consumables like the electrode holder, proven in 1000 welding tests. Its design combines the clamping sleeve and housing into one part, improving current transfer and heat dissipation, while eliminating the need to consider the clamping sleeve as a consumable. TIG welding, known for clean, precise weld seams, requires lightweight, easy-to-operate torches. The xFUME® TIG combines a ceramic protective part and suction nozzle for a slim design, ensuring good visibility and effective fume suction. Key advantages include reliable fume suction, excellent ergonomics, and compatibility with mobile fume suction devices equipped with W3 separation filters.

The xFUME® TIG fume suction torch features a patented nozzle with protection and suction functions, and highly durable consumables like the electrode holder, proven in 1000 welding tests. Its design combines the clamping sleeve and housing into one part, improving current transfer and heat dissipation, while eliminating the need to consider the clamping sleeve as a consumable. TIG welding, known for clean, precise weld seams, requires lightweight, easy-to-operate torches. The xFUME® TIG combines a ceramic protective part and suction nozzle for a slim design, ensuring good visibility and effective fume suction. Key advantages include reliable fume suction, excellent ergonomics, and compatibility with mobile fume suction devices equipped with W3 separation filters.

Technical data

| product: | xFUME® TIG 150 | xFUME® TIG 260W | xFUME® TIG 300W |

| Cooling specifications: | Air Cooling | Water Cooling | Water Cooling |

| Current (A) | |||

| DC: | 150 | 260 | 300 |

| Exchange: | 105 | 185 | 210 |

| Usage (%): | 35 | 100 | 100 |

| Electrode diameter-Ø (mm): | 1.0 – 2.4 | 1.0 – 3.2 | 1.0 – 3.2 |

| Suction flow rate m3 / h | |||

| Suction nozzle: | 14.8 | 14.8 | 14.8 |

| Connector: | 28.9 | 23.7 | 26.7 |