BINZEL JAPAN Ltd

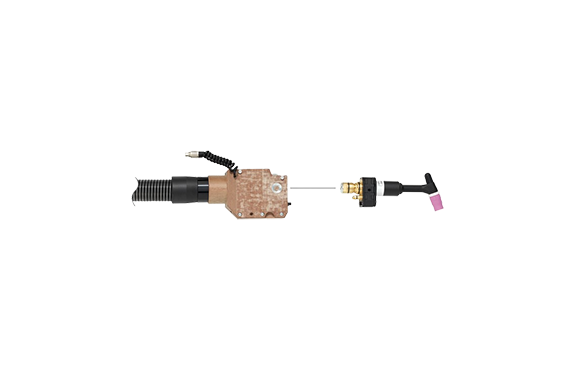

Binzel Japan WH Welding Torch System ABITIG®

Manufacturer: BINZEL JAPAN Ltd

Model: WH

Fast, safe & reliable …

The ABITIG® WH welding torch system from ABICOR BINZEL® for TIG soldering and TIG welding offers a high degree of process reliability for the joining a wide range of different materials.

Pre-set tungsten electrodes, reproducible torch replacement and servicing work done outside the robot cell guarantee consistently high quality and system availability.

With only two design sizes in different geometries, even for the most complex of components, the TIG welding torch system ABITIG® WH covers almost all automatic TIG applications. Also available with cold wire feeding according to the push or push-pull principle.

Advantages that speak for themselves:

Flexible and fast adaptation to changing welding tasks

Pre-set tungsten electrode

Reproducible torch position

With cold wire feeding and push-pull function

Liquid-cooled up to 400 A

Technically matured and 100% reliable

Automatic neck change available for maximum system up-time

Degree of automation: High

Typical areas of application:

Automobile construction

Bicycle industry

Container construction

Machine and steel construction

Aerospace industry

Material:

Chrome-nickel steels

Duplex steels

Nickel basic materials

Mixed compounds

Aluminium materials

Magnesium materials

Copper materials

Special materials

Robot interface:

Conventional robot (Cable assembly external):

Robot mount CAT2

Fixed bracket RTM

ABITIG® WH 220 W (liquid-cooled)

Technical data according to EN 60 974-7:

Cooling: liquid-cooled

Rating: 220 A DC / 160 A AC

Duty cycle: 100 %

Electrode-Ø: 1.0 – 3.2 mm

ABITIG® WH 400 W (liquid-cooled)

Technical data according to EN 60 974-7:

Cooling: liquid-cooled

Rating: 400 A DC / 280 A AC

Duty cycle: 100 %

Electrode-Ø: 1.6 – 4.8 mm