BINZEL JAPAN Ltd

Binzel Japan CAT3 PRO On A Welding Robot

Manufacturer: BINZEL JAPAN Ltd

Model: CAT3 PRO

High cycle times and high-volume production often lead to collisions with welding robots, damaging consumable parts, workpieces, or the torch itself. Frequent repairs cut into profits. The CAT3 PRO from ABICOR BINZEL solves this with automatic switch-off protection. Available in CR (cylindrical) and TR (conical) versions, it quickly shuts down on collision and allows rapid restart without re-teaching, designed for standard welding robots with cable armor.In particular: ABICOR BINZEL’s CAT3 PRO CR and CAT3 PRO TR eliminate the need for reprogramming of the welding robot when simply replacing the conventional torch mount:

CAT2

CAT2-HL

CAT3

CAT3 PRO Features

In harsh industrial environments, welding equipment must meet high daily demands. Quality and safety are prioritized to minimize downtime. The CAT3 PRO CR and CAT3 PRO TR torch mounts, with integrated switch-off protection, offer greater stability and robustness than CAT3, CAT2, and CAT2-HL. Improved repeatability (TCP) further reduces downtime. A key advantage: Customers using CAT2, CAT2-HL, or CAT3 can easily upgrade, as CAT3 PRO CR shares the CAT2 bracket mount, and CAT3 PRO TR matches CAT3 and CAT2-HL.

Robot Mount CAT3 PRO CR

Robot Mount CAT3 PRO CR

Differences between CAT2 and CAT3

More stable and sturdy.

Achieve accurate TCP.

No need to reprogram the welding robot.

CAT3 PRO Benefits at a Glance

As a new generation of universally applicable torch mounts for welding robots, CAT3 PRO offers solid protection, which can be briefly summarized as follows:

Higher performance through practical and robust design

Easy installation on welding robots

Highly reliable switch function

Accurate repeatability (TCP) and reduced system downtime

Easy tool weight adjustment with spring sizes XL, L, M (option: S)

Ease of replacement and repair

High protection against dirt

100% compatible with CAT2, CAT2-HL, and CAT3

Technical data for the robot mount CAT3 PRO

| size: | Outer diameter Φ77mm, height 106mm |

| weight: | 960g (excluding holder and flange) |

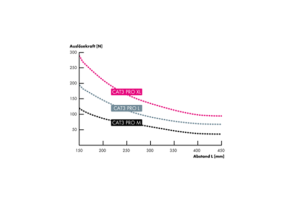

| Release Force: | (See Figure 1) Deviation CAT3 PRO CR/ CAT3 PRO TR |

| Switch Point: |

|

| Maximum deviation: |

|

| Reproducibility: | (See Figure 2) X-, Y-, Z-directions: ± 0.04 mm (400 mm from the robot flange) |

| Dust and water resistance standards: | IP 21 |

| Load capacity Safety devices: | Maximum 30V DC/100mA |

| environment temperature: |

|

| Relative humidity: |

|

Figure 1:

Release force of the robot mount CAT3 PRO CR and CAT3 PRO TR

The diagram below shows the static release force for different spring types as a function of the distance to the flange face (Figure 2).

Figure 2:

Maximum deviation of XY axis

Related Products

-

Binzel Japan Contact Tip Or Contact Tube For MIG/MAG Welding Torch

-

Binzel Japan ALPHA FLUX 350 Flux Cored Self-Shielding Welding Torch

-

Binzel Japan ROBO Compact W600 Welding Torch System

-

Binzel Japan SWR Spool Welding Robot

-

Binzel Japan GRIP 9, 26 Welding Torch ABITIG ®

-

Binzel Japan FES-200, FES-200 W3 Fume Extraction Systems