BINZEL JAPAN Ltd

BINZEL JAPAN EWR 2 / EWR 2 Net Gas Control And Management System

Manufacturer: BINZEL JAPAN.

Product: Gas Control And Management System

Model: EWR 2 / EWR 2 Net

Improved reduction rate and precision, and also compatible with Industry 4.0 specifications!

The EWR 2 system uses a patented method to control gas flow. It is synchronized with the welding current and can adjust the gas flow in real time using a high-speed solenoid valve. It is also properly controlled for ambient temperature, gas input pressure fluctuations, exhaust pressure fluctuations, etc. Compared to other general gas flow reduction systems, the EWR2 can achieve more gas flow reduction by stably adjusting the gas flow with high precision.

Advantages that speak for themselves:

- Reduced operating costs due to reduced gas flow

- Environmentally friendly, reduces CO2 emissions

- Highly accurate and optimized gas flow control system

- High-precision closed-loop control system regulates gas flow

- Easy handling and monitoring

- Various data can be saved

- ABICOR BINZEL Service Software for Windows PC and calculation and display of ROI

application:

- Can be used for various processes such as manual and automated welding

- Easy to install on existing and new equipment

- Applicable to all welding gas types

- Gas input pressure range: 1 – 6 bar

- Gas flow range: 2 – 30 l/min

Device List

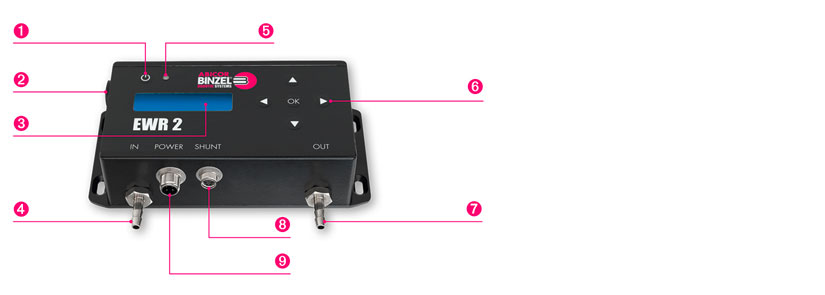

EWR 2:

The basics of effective gas management!

1. ON/OFF button

2. Link cable connection

3. Display

4. Gas Input

5. Status LED

6. Device settings button

7. Gas Output

8. Shunt Connection

9. Power Connection

All EWR 2 devices use a closed-loop gas flow control mechanism, which compares the actual gas flow rate with the set gas flow rate and adjusts it to the set gas flow rate with high speed and precision. All devices have an LED display that allows easy viewing of status and system parameters. Settings can be changed directly using the buttons on the device, or the device can be connected to a PC with ABICOR BINZEL service software installed via a stereo jack to change settings and obtain data.

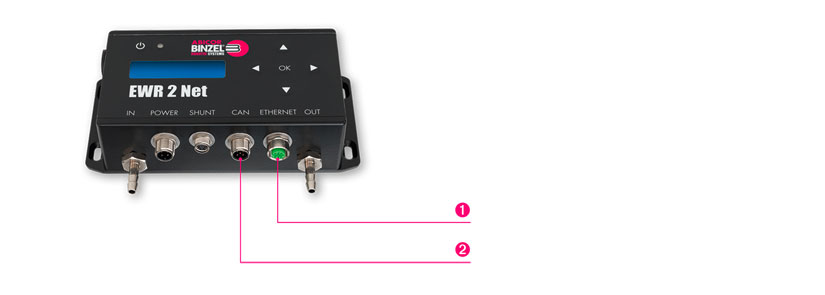

EWR 2 Net:

Easy connection with Industry 4.0!

1. Ethernet interface

2. CAN open interface

EWR 2 Net has two additional interfaces for flexible connection.

CAN open interface: allows connection to other fieldbus systems via additional gateways and allows real-time data exchange.

Ethernet interface: allows integration into local networks. With the ABICOR BINZEL service software installed on a PC, it is possible to connect to each EWR Net installed on site.

specification

| Operating voltage: | 24 V DC ±20% |

| Average temperature: | 10 – 40 °C |

| Ambient temperature: | -10 – +50 °C |

| Relative humidity: | 20 – 90% |

| Flow range: | 2 – 30 l/min |

| Flow Tolerance: | ±1 l/min |

| Shunt Type: | 150A / 300A / 500A |

| Gas Input Pressure: | 1 – 6 bar |

Other interfaces for EWR 2 Net:

- Ethernet Interface

- CAN Interface

Related Products

-

Binzel Japan ALPHA FLUX 350 Flux Cored Self-Shielding Welding Torch

-

BINZEL JAPAN DE 2200 / DE 2300 / DE 2400 / DE 2500 Electrode Holders

-

BINZEL JAPAN MFS-V3 Master Feeder System

-

Binzel Japan TSi Injection Unit

-

BINZEL JAPAN Ceramic protective spray

-

BINZEL JAPAN K12 / K12 T / K16 / K16 T Gouging Torch