Nakatani Co Ltd

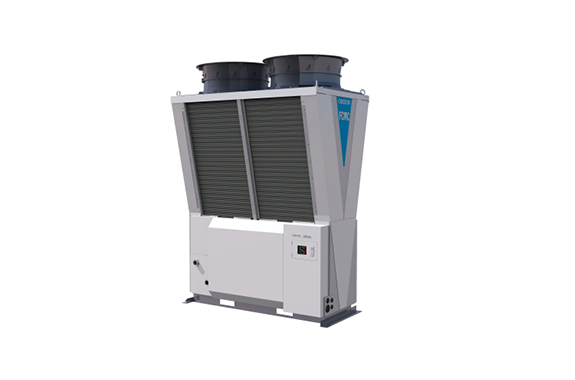

Nakatani FCMC55A Free Cooling Modular Eco Hybrid Chiller

Manufacturer: Nakatani Co., Ltd.

Model: FCMC55A

Features

This is a new chiller that combines a DC inverter chiller with a free cooling mechanism that makes maximum use of natural energy.

The free cooling mechanism does not spray water like a cooling tower, but is air-cool, so there is no scale build-up or algae growth, allowing for clean cooling.

Energy saving with three operating modes

The system automatically switches between three operating modes depending on the outside temperature, allowing for optimal control mode operation throughout the year, which enables significant reductions in power consumption.

Mode 1: Chiller operation

In summer when the outside temperature is high, it operates as a DC inverter chiller. The inverter controls according to the load, allowing it to operate with minimal power.

Mode 2: Free cooling operation + chiller operation (auxiliary)

In intermediate seasons such as spring and autumn, free cooling is the main mode of operation. When cooling is insufficient due to a rise in the outside temperature, the chiller comes in to assist.

Mode 3: Free cooling operation

During winter when the outside temperature is low, the system operates on free cooling only. This reduces electricity consumption other than for the fan and circulation pump, which can lead to significant energy savings.

For medium temperature range (water temperature 15℃ to 35℃)

By limiting the set temperature to the medium range of 15 to 35°C, energy savings during free cooling are achieve

Especially in winter when the outside temperature is low, significant energy savings can be expect because the unit operates on free cooling only (mode 3).

Modular Cooling System

Reduce the risk of a complete outage

The FCMC55A is made up of two refrigeration cycles. In the unlikely event that an abnormality occurs in one of the refrigeration cycles and it stops, the other normal refrigeration cycle will continue operation, dispersing the risk of a complete shutdown.

New shape “V shape”

Our proprietary “V-shape” is use to reduce the installation space required for module installation. This allows for close installation while still ensuring maintenance space.

A wide range of connection patterns

Multiple connection patterns are available. We will propose the optimal connection pattern to customers so as not to waste limited space.

Module controller [Required optional item]

By connecting the “module controller”, a required optional item, to each unit, functions such as unit number control operation and rotation operation can be used.

Easy maintenance/Warning display

You can check which module chiller an alarm occurred in. By touching “Details”, you can check the alarm content, etc.

Group Controller [Accessory (sold separately)]

It enables centralized management of groups under the control of a module controller. Not only can you start/stop the units, but you can also remotely change various settings such as the set temperature.

Operate and monitor up to 32 modules

Multiple groups (up to 4 systems) with different temperature zones under the control of a module controller can be centrally managed.

Applications

Crusher: Jacket cooling

Cleaning machine: Hydrocarbon-based, recovery applications, distillation and recycling of various solvents Resin

molding machine: Mold cooling after molding (promoting resin hardening after molding)

Laser processing machine (fiber, CO2, YAG): Oscillator and optical circuit cooling

Printing machine (DI): UV irradiator cooling, cooling stage cooling, ink temperature control

High-frequency induction heating device: Heating coil cooling, high-frequency power supply cooling

Water-cooled compressor: Cooling water for water-cooled compressors