Fushiman Co.

Fushiman RK86 type check valve

Manufacturer: Fushiman Co.,LTD.

Model: RK86

| Model | Nominal diameter | Fluid | Maximum Operating Pressure | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|

| RK86 | 15 to 200 | Steam Gas Liquid | 4.0 MPa | 300°C | Martensitic stainless steel (equivalent to SUS420) | Wafer |

Wafer type, compact, and lightweight — installation orientation is optional.

Specifications

| Model | RK86-RK86A | ||||||||||

| Description | The maximum operating pressure and temperature vary depending on the flange standard. Metal seat types exceeding 300°C can also be manufactured. | ||||||||||

| Type of Disc Contact Surface | Metal Seat | Soft Seat | |||||||||

| Applicable Fluid | Liquid, gas, and steam | Water, condensate, and steam | Mineral oil | Gas and air | |||||||

| Maximum Operating Pressure (MPa) | 4.0 | 3.3 | 3.0 | 2.6 | 4.0 | 3.3 | 3.2 | 4.0 | 3.3 | 3.1 | |

| Maximum Operating Temperature (°C) | 20 | 100 | 200 | 300 | 20 | 100 | 120 | 20 | 100 | 160 | |

| Material | Disc | Stainless Steel | EPDM | Fluororubber | |||||||

| Body & Seat (Integral) | RK86 type (Nominal diameter 15–100): Martensitic stainless steel RK86 type (Nominal diameter 125–200): Carbon steel RK86A type (Nominal diameter 15–200): Austenitic stainless steel | ||||||||||

| Spring | Stainless steel | ||||||||||

| Pipe Connection: Compatible Flanges | JIS 10K (Nominal diameter 15–100 only) JIS 16K/20K (All nominal diameters except 50–80) DIN PN10/16/25/40 (All nominal diameters) ASME Class 150/300 RF (All nominal diameters) | ||||||||||

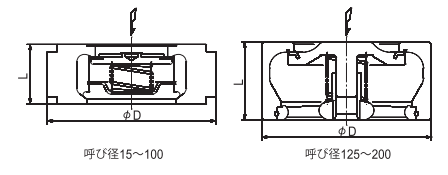

Structure and Dimensions

| Model | RK86- | RK86A | |||||||||||||

| Nominal Diameter | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |||

| Dimensions | L | 16 | 19 | 22 | 28 | 31.5 | 40 | 46 | 50 | 60 | 90 | 106 | 140 | ||

| D | Min | 44 | 53 | 64 | 73 | 83 | 96 | 110 | 158 (132)(1) | 151 | 194 (216)(2) | 220 (251)(2) | 275 (308)(2) | ||

| Max | 67 | 76 | 82 | 93 | 104 | 118 | 136 | 186 | |||||||

| Opening Pressure | Installation Orientation | Without Spring | ↑ | 0.25 | 0.25 | 0.25 | 0.35 | 0.40 | 0.45 | 0.50 | 0.55 | 0.65 | 1.25 | 1.40 | 1.35 |

| With Spring | ↑ | 1.00 | 1.00 | 1.00 | 1.20 | 1.30 | 1.40 | 1.50 | 1.60 | 1.80 | 3.50 | 3.80 | 3.70 | ||

| → | 0.75 | 0.75 | 0.75 | 0.85 | 0.90 | 0.95 | 1.00 | 1.05 | 1.15 | 2.25 | 2.40 | 2.35 | |||

| ↓ | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 1.00 | 1.00 | 1.00 | |||

| Cv Value | 4.3 | 7.9 | 12 | 18 | 27 | 43 | 68 | 90 | 135 | 262 | 345 | 597 | |||

| Weight | 0.3 | 0.4 | 0.5 | 0.8 | 1.1 | 1.8 | 2.5 | 3.4 | 5.4 | 11 | 14 | 25 | |||

Note (¹): Exclusive for JIS 20K. Values in parentheses are for JIS 10K. Nominal diameter 80 is not available in that specification.

Note (²): Values in parentheses are for ASME Class 300 RF.

Remark: The allowable tolerance for opening pressure is ±20%. Do not use for pressure regulation purposes.

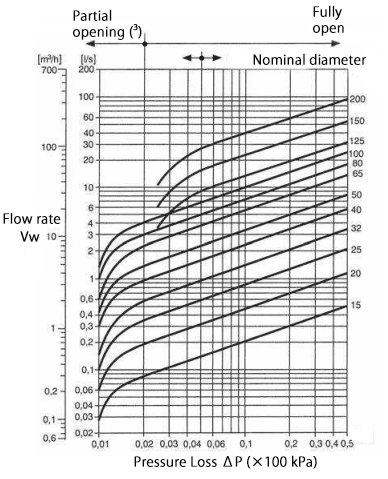

Pressure Loss

Note (³): Do not use under partial opening conditions (when pressure loss ΔP is 2 kPa or 5 kPa or less), as chattering may occur.

- The graph shows data for water at 20°C.

- To determine the pressure loss for other fluids, read the graph using the equivalent flow rate calculated as follows:

Vw = V × ρ / 1000

Vw: Equivalent flow rate (ℓ/s or m³/h)

ρ: Fluid density (operating) (kg/m³)

V: Actual flow rate (operating) (ℓ/s or m³/h) - The graph is based on horizontal piping.

- For vertical piping, there may be slight differences before the valve is fully open. Once fully open (normal flow condition), it is the same as for horizontal piping.