Fushiman Co.

Fushiman AAS40-3F and AAS40-3CF automatic air vent valves

Manufacturer: Fushiman Co.,LTD.

Model: AAS40-3F

| Model | Nominal diameter | Fluid | Maximum Operating Pressure | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|

AAS40-3F | 20 | water | 1.0 MPa | 80°C | SUS316L-CP | Screw in |

It is ideal as an air release valve for stainless steel piping.

Features

When the valve is closed, the structure completely separates the valve body from the float, preventing water leakage due to pipe vibration or pulsation.

All parts are made from non-corrosive materials, eliminating the risk of rust-contaminated water.

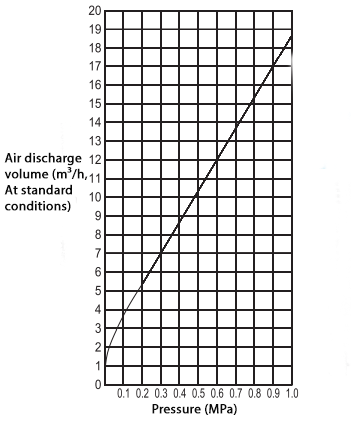

Thanks to a unique design, it achieves a very high air discharge capacity despite its compact size.

The float is made of molded synthetic resin, so there is no risk of collapse or water absorption.

In the unlikely event of leakage, it can be prevented by tightening a hose clamp on the outlet side. This is also effective when the inlet of the air release valve is not sealed.

The AS40A-3F model quickly draws in a large volume of air when the piping or equipment is under negative pressure, preventing damage.

The AS40A-3CF model has a built-in check valve on the outlet side and a strainer on the inlet side, preventing air from being drawn in even if the piping or equipment is under negative pressure.

Specifications

| Model | AAS40-3F | AAS40-3CF | |

| Structure | Check valve | None | Included |

| Strainer | None | Included | |

| Applicable fluid | Cold and hot water | ||

| Nominal diameter | 20 | ||

| Maximum operating pressure | 1.0 MPa | ||

| Maximum operating temperature | 80°C | ||

| Materials | Valve body | Stainless steel | |

| Valve | Synthetic rubber | ||

| Valve seat | Stainless steel | ||

| Float | Synthetic resin | ||

| Pipe connection | Threaded type JIS Rc | ||

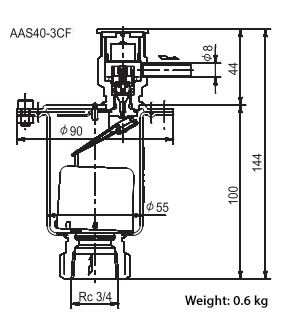

Structure / Dimensions

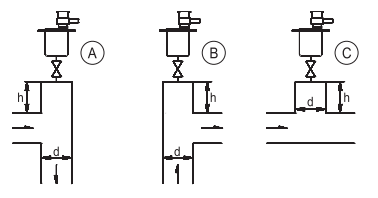

Installation Example

Please install at the top of the piping in all cases.

Making h as long as possible and d as thick as possible makes bubble separation especially easy.

Precautions When Installing

Install the unit as vertically as possible at the highest point of the piping or equipment.

Attach a stop valve on the inlet side to allow for water shutoff during maintenance and inspection.

When starting the system for the first time, close the stop valve above, and thoroughly flush the piping to remove any debris and prevent foreign objects from entering the air release valve. After that, fully open the stop valve.

There is a risk that debris may stick to the valve body and cause water leakage. Therefore, insert an 8 mm inner diameter vinyl tube into the valve outlet and direct it to a drain or safe discharge point.

For further handling instructions, please read the instruction manual included with the product.