Fushiman Co.

Fushiman RVD19-2 type vacuum breaker

Manufacturer: Fushiman Co.,LTD.

Model: RVD19-2

| Model | Nominal diameter | Fluid | Maximum Operating Pressure | Maximum Operating Temperature | Body Material | Connection |

|---|---|---|---|---|---|---|

| RVD19-2 | 20-50 | water | 1.0 MPa | 90°C | CAC406 | Screw in |

This is a basic vacuum breaker with over 20 years of proven performance. It operates reliably with a simple structure.

If the piping or container becomes vacuumed and left as is, it may cause backflow or result in the container being crushed.

The RVD19-2 model quickly draws in air to break the vacuum when the piping or container is vacuumed.

Note: A check valve can be installed upstream of the RVD19-2 model to prevent backflow.

Features

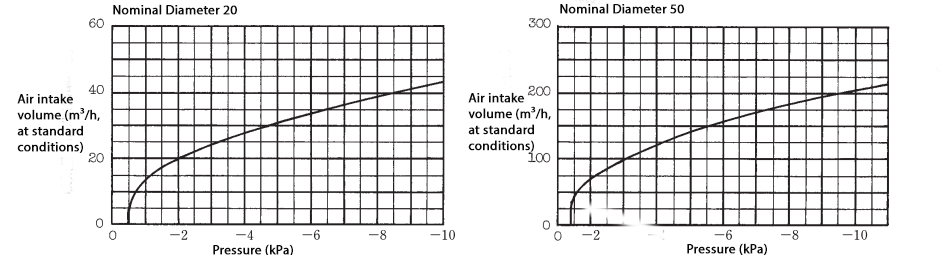

Breaks vacuum quickly with a large suction volume.

Operates reliably with a very small pressure difference due to its diaphragm shape.

Maintains stable operation even under long-term pressure (up to 1 MPa) and temperature (up to 90°C).

All wetted parts are made of corrosion-resistant materials, so there is no concern about rust.

The valve body uses synthetic rubber, providing excellent sealing performance.

Specifications / Performance

| Fluid | Cold and hot water |

| Nominal diameter | 20・50 |

| Max operating pressure (MPa) | 1 |

| Max operating temperature (°C) | 90 |

| Min operating pressure (kPa) | −1.5 or lower |

| Valve body | Bronze |

| Diaphragm valve body | Synthetic rubber |

| Strainer | Stainless steel |

| Pipe connection | Threaded type JIS Rc |

| Application | Vacuum breaking for cold/hot water piping in refrigerators, hot water appliances, pools, bathrooms, dishwashers, medical equipment, etc. Also prevents negative pressure damage in air piping systems. |

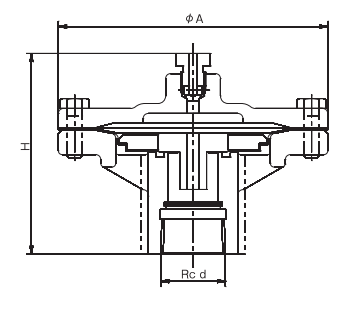

Structure / Dimensions / Weight

| Nominal Diameter | 20 | 50 | |

| Dimensions | d | ¾ | 2 |

| H | 80 | 109 | |

| A | 108 | 140 | |

| Weight | 1.5 | 4 | |

Air Intake Volume

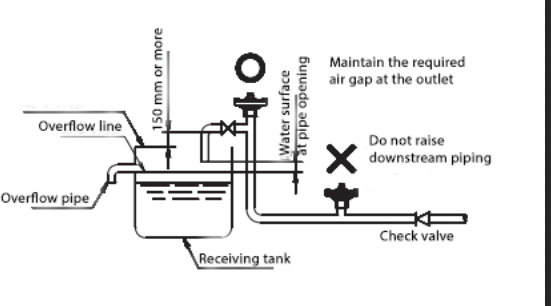

Usage Example

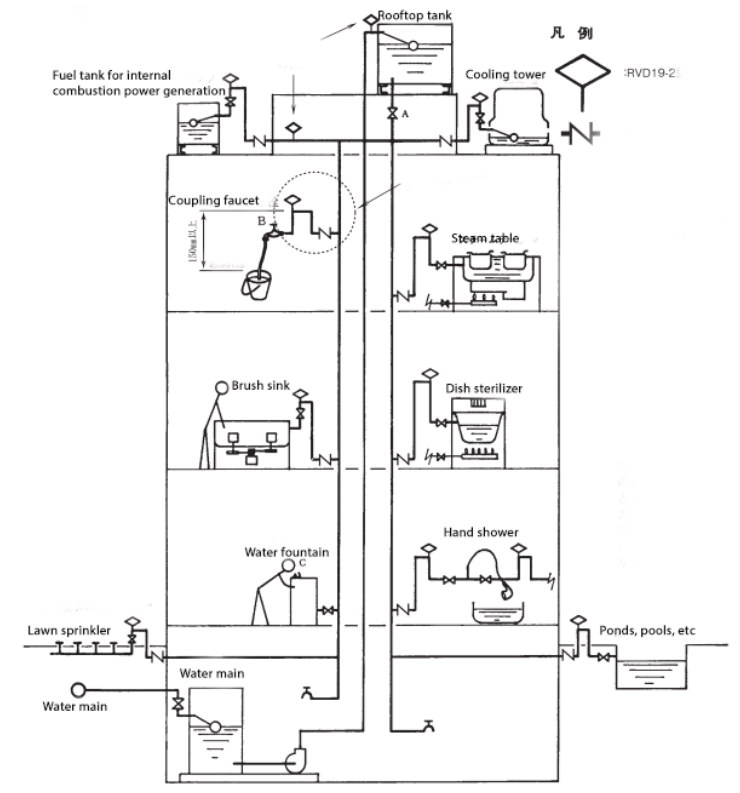

If a vacuum breaker is not installed in the diagram and, for some reason, valve A is closed, while a hose is submerged in a bucket at point B and water is drawn from a water fountain or another outlet at point C, the supply pipe may fall into negative pressure.

This can cause a reverse siphon effect, sucking water from the bucket into the drinking water system, leading to contamination.

However, if an RVD19-2 model is installed as shown in the diagram, when valve A is closed and negative pressure occurs near point B, the RVD19-2 quickly draws in air, preventing water from the bucket from being sucked into the system.

Precautions for Use

- Do not raise the downstream piping of the vacuum breaker.

- The vacuum breaker alone does not have a backflow prevention function. If used for backflow prevention, raise the pipe by at least 150 mm above the vacuum breaker as shown in the diagram, and install a check valve upstream of the vacuum breaker.

- Install it in a clean location and do not insulate the air intake opening.

- To prevent unexpected water leakage from the air intake, install it in a safe and drainable location.

Note:

If the water supply tank, etc., is filled above the inlet level, or if there is a risk of the water surface being higher than the tank, install a check valve and vacuum breaker to prevent backflow.

Also, install RVD19-2 where there is a risk of siphoning due to a sudden pressure drop.