MANABE ZOKI CO., LTD.

MANABE ZOKI MDR Series Slim Type Deck Crane

Manufacturer: MANABE ZOKI CO., LTD.

Model: MDR Series

In recent years, requests for the optimum use of space on deck, rationality, and efficiency of loading work have increased. To meet these requests, deck crane styles are also increasing, as are traditional derrick loading styles.

We have been manufacturing the “Manabe-Hydraulic Deck Crane” with our long experience in high-pressure hydraulic-type deck machinery and our exceptional skill.

MANABE-HYDRAULIC DECK CRANE got “easy control” mechanics, which is the advantage of hydraulic, and we are considering how to reduce reliance on endurance in any weather, etc.

FEATURES

GREAT EFFICIENCY

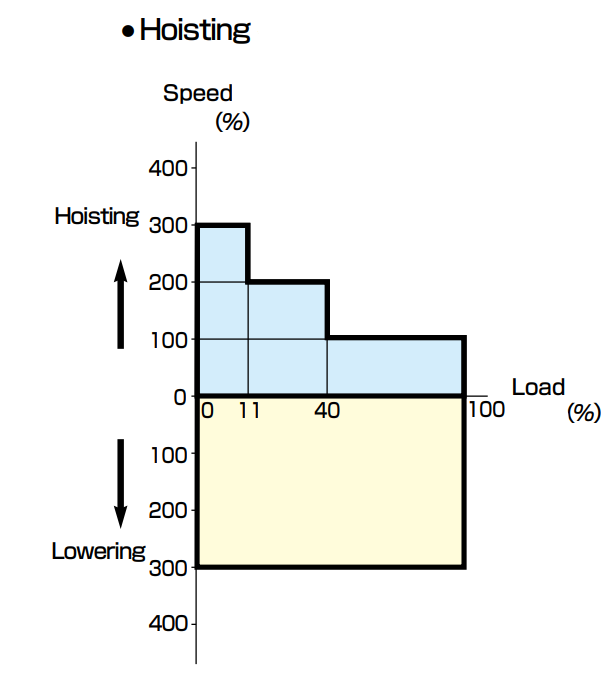

The hoisting speed can be automatically changed in three steps for each load.

Especially, the 「MANABE-HYDRAULIC DECK CRANE」 is capable of over three times as normal speed when you hoist with light loads or lower with any loads. (Standard type)

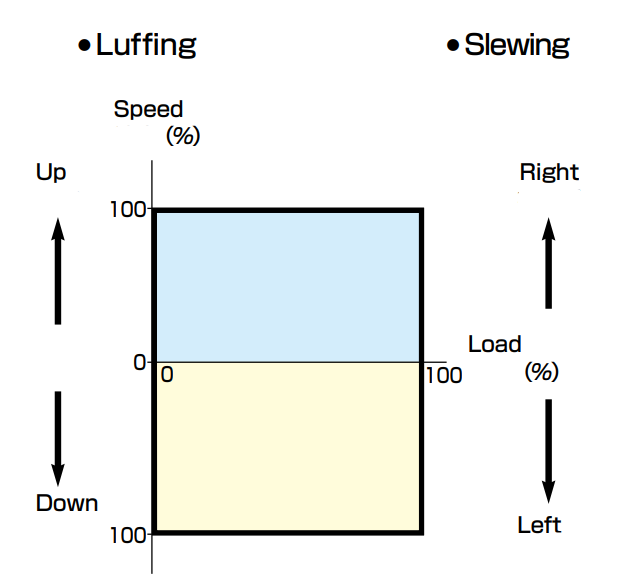

In addition, you can operate easily with two control levers (for hoisting, luffing, and slewing), so you can work efficiently by smoothly controlling the speed smoothly for each angle.

WIDE CARGO SPACE

- Wide space is secured for work by reducing the minimum slewing radius, and it is possible to use the space on deck effectively.

COMPACT INSTALLATION SPACE

- It is possible to reduce installation space because of the inside access from fixed post to cab. (For the deck crane of over 245kN capacity) Acquired AWWF.

EASY TEST and MAINTENANCE

- MANABE winches and the hydraulic equipment in crane house are high-pressure type and compact, besides optimum position, so you can test and manage easily.

VARIOUS SAFE DEVICES

- 「MANABE-HYDRAULIC DECK CRANE」 equips various safe devices which are limit devices of hoisting and luffing, besides the float switch and thermo switch.

If any trouble happened such as power cut during a cargo handling, the cargo handling will stop immediately with the mechanical brake of spring-on type and counterbalance valve installed on each hydraulic motor

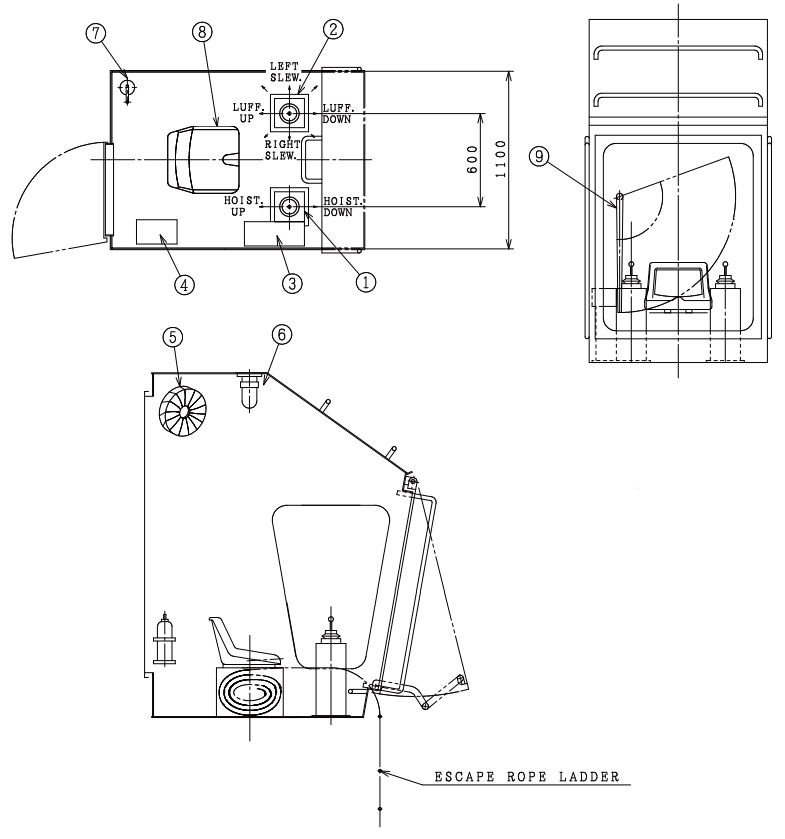

Cab

① Control stand for hoisting

② Control stand for luffing & slewing

③ Control panel

④ Heater

⑤ Fan

⑥ Room lamp

⑦ Fire extinguisher

⑧ Operator’s chair

⑨ Window wiper

Equipment

Equipment in the cab & machine room

・Control stand for hoisting

・Control stand for luffing and slewing

・Control panel

・Heater (1kW)

・Fan

・Room lamp

・Fire extinguisher

・Receptacle

・Screen wiper (manual type)

・Front openable window

(natural ventilation and emergency escape)Other equipment

・Cargo lamp: mercury lamp (400W × 2sets)

・Falling block (swivel with hook)

・Fixing bolt (with plain washer)

for mounting a crane: 1 set

・Equalizing beam (for only twin crane)

・Jib top piece for jib rest (standard length: 0.5m)

Optional Equipment

・Additional cargo lamp

・Crane post installed on the vessel

・Slewing limit device

・Attachments for grab-handling

・Protector around a crane for lumber-handling

Characteristic Curve

Standard(MDW-30※※S-115)

Safety Devices

MANABE-HYDRAULIC DECK CRANE has various safety devices for preventing from damage caused by mishandling or unskilled operation.

1 Upper limit device for hoisting (full drum)

2 Lower limit device for hoisting (empty drum)

3 Upper limit device for luffing (min. radius)

4 Lower limit device for luffing (max. radius)

5 Limit device for luffing at jib rest position

6 Differential limit device for preventing

the collision of the hook and the jib top

7 Slack-over detector

8 Emergency stop pushbutton

9 By-pass button for jibrest

10 Oil level detector in the head tank

11 Thermal detector of working oil

12 Automatic start or stop device of the oil cooler

13 Safety valves

The following safety devices are provided for twin crane in addition to safety devices of each single crane.

- 1 Synchronous control device for hoisting of master and slave crane

2 Synchronous control device for luffing of master and slave crane

3 Slewing limit device for preventing collision of two single crane under single mode operation

Specification

| Type | Hoisting Load (ton) | Slew.Radius | Hoisting Speed (txm/min) | Lowering Speed (m/min) | Luffing Time (sec) | Slewing Speed (min⁻¹) | Electric Motor for Pump Unit | Mass. (t) | |

|---|---|---|---|---|---|---|---|---|---|

| Max.(m) | Min.(m) | ||||||||

| MDR-3020S-115 | 30.7 | 20 | 3.0 | 30.7X21 12×42 3.5X63 | 63 | 50 | 0.70 | 115KW CONT. 270kW 15%ED | 39 |

| MDR-3022S-115 | 22 | 50 | 0.70 | 40 | |||||

| MDR-3024S-115 | 24 | 56 | 0.65 | 41 | |||||

| MDR-3026S-115 | 26 | 60 | 0.60 | 44 | |||||

| MDR-3028S-115 | 28 | 66 | 0.60 | 46 | |||||

| MDR-3030S-115 | 30 | 3.5 | 66 | 0.45 | 49 | ||||

| MDR-3032S-115 | 32 | 68 | 0.45 | 51 | |||||

| MDR-3020S-150 | 30.7 | 20 | 3.0 | 30.7X26 3.5X52 | 52 | 50 | 0.70 | 150kW CONT. 360kW 15%ED | 40 |

| MDR-3022S-150 | 22 | 50 | 0.70 | 41 | |||||

| MDR-3024S-150 | 24 | 56 | 0.65 | 42 | |||||

| MDR-3026S-150 | 26 | 60 | 0.60 | 45 | |||||

| MDR-3028S-150 | 28 | 66 | 0.60 | 47 | |||||

| MDR-3030S-150 | 30 | 3.5 | 66 | 0.45 | 50 | ||||

| MDR-3032S-150 | 32 | 68 | 0.45 | 52 | |||||

| MDR-3620S-115 | 36 | 20 | 3.0 | 36×18 14×36 4×60 | 60 | 60 | 0.60 | 115KW CONT. 270kW 15%ED | 45 |

| MDR-3622S-115 | 22 | 60 | 0.60 | 46 | |||||

| MDR-3624S-115 | 24 | 65 | 0.50 | 48 | |||||

| MDR-3626S-115 | 26 | 66 | 0.50 | 48 | |||||

| MDR-3628S-115 | 28 | 66 | 0.45 | 53 | |||||

| MDR-3630S-115 | 30 | 3.5 | 66 | 0.40 | 55 | ||||

| MDR-3632S-115 | 32 | 68 | 0.40 | 59 | |||||

| MDR-3620S-150 | 36 | 20 | 3.0 | 36×22 4×44 | 44 | 60 | 0.60 | 150kW CONT. 360kW 15%ED | 46 |

| MDR-3622S-150 | 22 | 60 | 0.60 | 47 | |||||

| MDR-3624S-150 | 24 | 65 | 0.50 | 49 | |||||

| MDR-3626S-150 | 26 | 66 | 0.50 | 52 | |||||

| MDR-3628S-150 | 28 | 66 | 0.45 | 54 | |||||

| MDR-3630S-150 | 30 | 3.5 | 66 | 0.40 | 56 | ||||

| MDR-3632S-150 | 32 | 68 | 0.40 | 60 | |||||

| MDR-4020S-115 | 40 | 20 | 3.0 | 40×16 16×32 5×52 | 52 | 70 | 0.55 | 115KW CONT. 270kW 15%ED | 48 |

| MDR-4022S-115 | 22 | 70 | 0.55 | 49 | |||||

| MDR-4024S-115 | 24 | 70 | 0.45 | 51 | |||||

| MDR-4026S-115 | 26 | 78 | 0.45 | 52 | |||||

| MDR-4028S-115 | 28 | 80 | 0.45 | 56 | |||||

| MDR-4030S-115 | 30 | 3.5 | 80 | 0.40 | 59 | ||||

| MDR-4032S-115 | 32 | 80 | 0.40 | 61 | |||||

| MDR-4020S-150 | 40 | 20 | 3.0 | 40×20 5X40 | 40 | 70 | 0.55 | 150kW CONT. 360kW 15%ED | 49 |

| MDR-4022S-150 | 22 | 70 | 0.55 | 50 | |||||

| MDR-4024S-150 | 24 | 70 | 0.45 | 52 | |||||

| MDR-4026S-150 | 26 | 78 | 0.45 | 55 | |||||

| MDR-4028S-150 | 28 | 80 | 0.45 | 57 | |||||

| MDR-4030S-150 | 30 | 3.5 | 80 | 0.40 | 60 | ||||

| MDR-4032S-150 | 32 | 80 | 0.40 | 62 | |||||

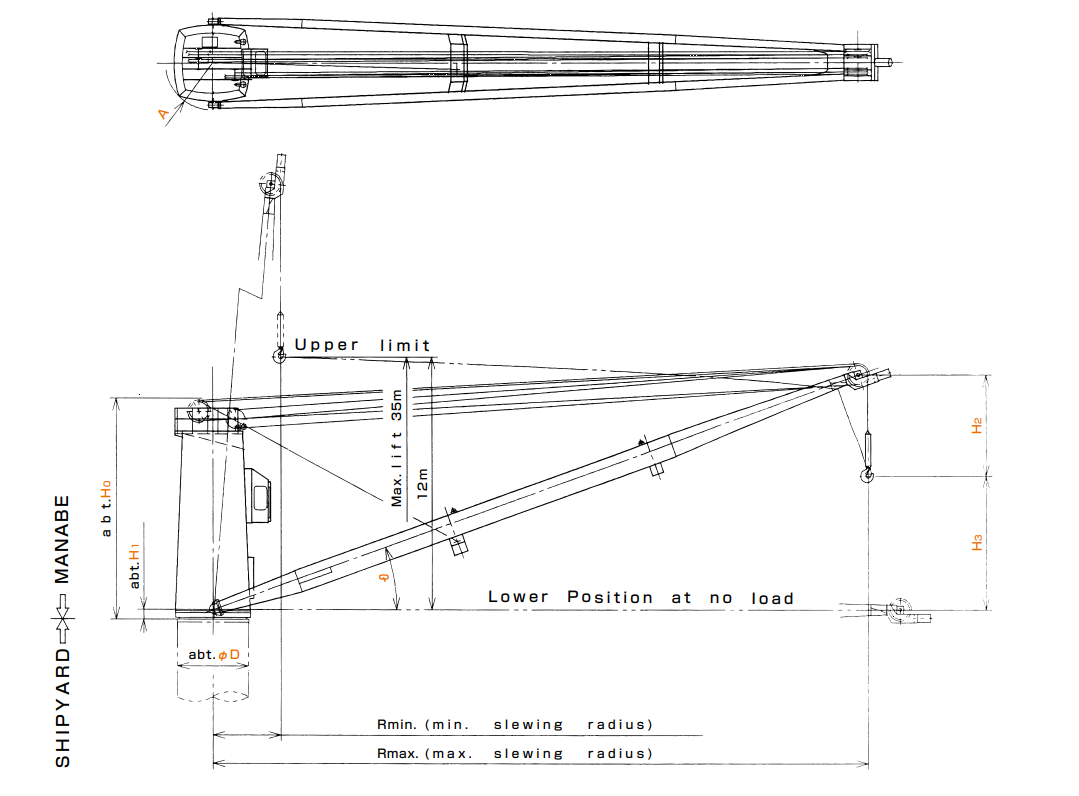

Common Particulars

1 Access : Inside

2 Max. Lift : 35m

3 Allowable list of ship

Cargo handling: 5 (°=3°heel +2 cargo swing ° ), 2(trim) °

Cargo swing in min.slewing radius area is not included.

Sailing : 35°

4 Simultaneous operation

At no load or list 0°under loading.

Speed at load for hoisting is 40%(High Speed Type)

5 Slewing angle : 360° endless

6 Electric source : AC3φ 440V 60Hz

: AC1φ 100V 6

Dimensions

<

| Type | Hoisting Load (ton) | Slew.Radius | Jib angle at Max. Slew.Radius | Dimension (m) | Crane Post | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max(m) | Min.(m) | H0 | H1 | H2 | H3 | A | ΦD (m) | Tilting Moment (kN m) | |||

| MDR-3020S | 30.7 | 20 | 3.0 | 25° | 8.9 | 0.40 | 3.5 | 5.7 | 2.8 | 2.6 | 7387 |

| MDR-3022S | 22 | 6.6 | 8162 | ||||||||

| MDR-3024S | 24 | 20° | 5.1 | 8966 | |||||||

| MDR-3026S | 26 | 5.8 | 9751 | ||||||||

| MDR-3028S | 28 | 9.1 | 6.6 | 10595 | |||||||

| MDR-3030S | 30 | 3.5 | 7.3 | 11380 | |||||||

| MDR-3032S | 32 | 8.0 | 3.0 | 2.8 | 12263 | ||||||

| MDR-3620S | 36 | 20 | 3.0 | 25° | 9.0 | 0.40 | 3.5 | 5.6 | 2.8 | 2.6 | 8711 |

| MDR-3622S | 22 | 6.6 | 9633 | ||||||||

| MDR-3624S | 24 | 20° | 5.1 | 10556 | |||||||

| MDR-3626S | 26 | 5.8 | 11331 | ||||||||

| MDR-3628S | 28 | 9.3 | 6.6 | 3.0 | 2.8 | 12459 | |||||

| MDR-3630S | 30 | 3.5 | 7.3 | 13440 | |||||||

| MDR-3632S | 32 | 9.4 | 0.50 | 8.0 | 14421 | ||||||

| MDR-4020S | 40 | 20 | 3.0 | 25° | 9.1 | 0.40 | 4.0 | 5.1 | 3.0 | 2.8 | 9712 |

| MDR-4022S | 22 | 6.1 | 10889 | ||||||||

| MDR-4024S | 24 | 20° | 4.6 | 11870 | |||||||

| MDR-4026S | 26 | 9.3 | 5.3 | 12851 | |||||||

| MDR-4028S | 28 | 6.1 | 13930 | ||||||||

| MDR-4030S | 30 | 3.5 | 9.4 | 0.50 | 6.8 | 15107 | |||||

| MDR-4032S | 32 | 7.5 | 16285 | ||||||||