NITIVY

NIVITY Solvron Water-Soluble Yarn

Solvron™ Water-Soluble Yarn

Solvron™ is a special yarn that is soluble in plain warm or hot water.

We have a wide range of product types depending on thickness and dissolving temperature, and the yarn is widely used to save labor in manufacturing processes and to add value to products.

Characteristics of Solvron™

- Tenacity

- High tenacity as a water-soluble yarn.

- Fineness

- Produced in a wide range of fineness 31-330dtex.

- Solubility

- Dissolvable at temperatures 30- 95℃ or higher.

- Shrinkability

- High shrinkage in water type is also available.

- Dyed yarn

- Red and blue dyed types are also available.

- Biodegradability

- Environmentally-friendly materials are used for the raw materials, which are degradable by micro-organisms.

Acquisition of OEKO-TEX®Standard 100 Certification Product Class I

Solvron™ has acquired Product Class I, the most strict standard of the OEKO-TEX® Standard 100 Certification.

OEKO-TEX® Standard 100 Certification

This certifies that textile products do not contain harmful chemical substances with the world’s highest safety standard for more than 350 harmful substances.

Product Class

The regulatory value standards grow stricter the closer a product is to bare skin, including contact with sensitive skin such as that of babies. Class I has the most stringent standards and has been proven to be safe for use with baby-related products.

Class I Articles for babies and toddlers Class Ⅱ Articles with direct contact to the skin Class Ⅲ Articles without direct contact to the skin Class Ⅳ Home textiles Solvron™ Usage Example

Solvron™ is used in many applications, taking advantage of its unique characteristics.

Improving Productivity and Added Functionality

For production of twistless yarn, hard-twist yarn and hollow yarn

For reinforcement of ultra-fine yarn / fluffy yarn

For open work design of woven fabric

For pile-knit fabric without using a special machineSolvron™ dissolves in water and does not remain in final products, but is used to add value to fibers by reinforcing fibers used together, softening the texture, and saving labor in the manufacturing process.

Properties Table

Type Temperature for dissolving treatment Size Availavle

(T:dtex / F:filament)Dry tenacity

(cN/dtex)Dry elongation

(%)Solubility in water

(℃)Shrinkage in water

(%)Shrinkage stress in water

(cN/dtex)Maximum

(water temperature)At 25℃ At 25℃ SH 95℃ or higher

(203°F)62T/18F 3.3~4.3 11~18 89~97 35~55

(85℃)0~5 0.04~0.15 SF 55℃ or higher

(131°F)31T/12F

44T/12F

62T/24F

88T/24F

110T/25F

220T/50F

330T/100F3.3~4.4 11~24 31~41 40~60

(40℃)ー 0.10~0.30 SS 30℃ or higher

(86°F)62T/18F

110T/30F

220T/60F2.7~3.7 15~25 15~24 ー ー ー Dope dyed yarn SF 55℃ or higher

(131°F)62T/18F(Red/Blue) 3.2~4.2 11~21 31~41 40~60

(40℃)– 0.10~0.30 High-Shrinking yarn SHC 90℃ or higher

(194°F)250T/100F 3.8~5.0 10~18 81~89 55~65

(60℃)40~50 0.20~0.40 * The following is also available. [Twist yarn / Ply yarn]

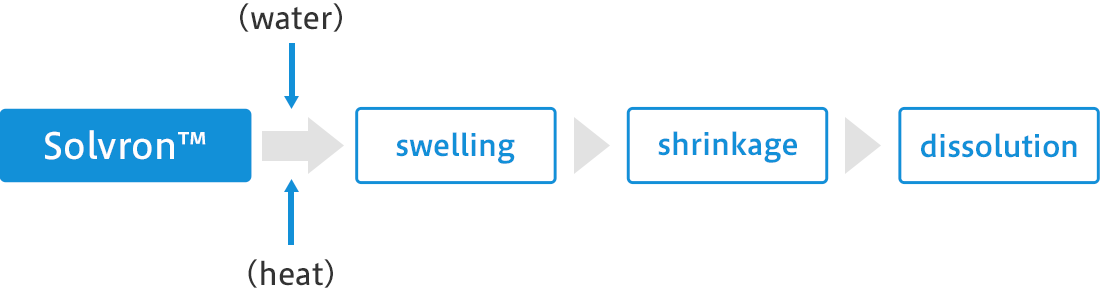

Solvron™ is a water-soluble vinylon made using polyvinyl alcohol (PVA).

It dissolves in water through the process shown in the diagram.

<Cautions when using>

Temperature and humidity control

Please take care to keep dry, as Solvron™ is likely to be influenced by humidity.

For example, opening a box of Solvron™ that has just been transferred from a cold storage area to a warm working area may cause condensation to form on the surface of the yarn. This, in turn , can lead to partial dissolving and difficulty with unreeling.

Boxed Solvron™ should be given 24-48 hours to adapt to any significant change in temperature before the box is opened.Storage Methods

Avoid high temperature and humidity. For long-term storage, store at a temperature of 15-25℃ and humidity of 50-70% RH.

Restrictions on Use

Solvron™ shrinks rapidly when wet. Do not immerse it in water while wrapped around a body part, as it is dangerous.

Dissolving Method

Please note the following to save energy and improve the quality of the product.

1. Dissolution Temperature

- Depending on the type of Solvron™ used, please heat up the treatment bath water to the desired temperature in advance before adding the material to be dissolved.

- During the dissolution process, please continue heating to maintain the temperature of the treatment bath water.

2. Dissolution Bath Ratio

- Please use a large amount of bath water to disperse the dissolved Solvron™.

(The suitable bath-ratio of water to Solvron™ is 1:30 based on weight)

3. Dissolving Time

- The dissolving time differs depending on the usage conditions.

Ex.) It takes about 10-20 minutes if the Solvron™ is in direct contact with the treatment bath water, and about 30-60 minutes depending on the extent of weaving and knitting.

4. Dissolution Facilitation

- It is easier for the material to dissolve, if it has less tension and the treatment bath is stirred sufficiently.

5. Rinsing

- After dissolving the Solvron™, rinse the material again in overflowing new warm water to completely remove the Solvron™.

(Note) If the Solvron™ remains after the Solvron™ dissolution process and is left to dry, it is extremely difficult to re-dissolve it.

6. Factors Affecting Dissolution

- When dry heat setting, the temperature for dissolving treatment may increase depending on the temperature.

- If tension is applied during dissolution, the temperature for dissolving treatment may increase.

- Solubility will decrease in the presence of formalin, heavy metals or other materials.

(Note) Dissolution may not always be possible, depending on the circumstances.

7. Wastewater Treatment

- The activated sludge method is effective in treating wastewater with Solvron™.

- The activated sludge method is an environmentally friendly method of wastewater that uses sludge with activated ability (a mass of microorganisms) to treat sewage and wastewater.

Solvron™ fields of use and examples

Apparel / Home Textiles

・Towel

・Shirts

・Sweater

・Lace

・Other woven and knitted products

Industrial Materials

・Automotive: interior materials, heat-resistant cushioning materials, airbag parts

・Covers for rollers in offset printing machines

・Fishing nets