Nachi

Nachi AQUA Drill EX FLAT Oil-Hole

Manufacturer: NACHI

Product name: AQUA Drill EX FLAT Oil-Hole

Features

Hole enlargement is reduced and a wide range of work materials are supported

●○ Applicable from carbon steel. alloy steel and cast iron to stainless steel. ○ Amount of oversize is reduced due to a double margin and the shape of the negative rake blade tip.

| Material Type | Details | Available |

|---|---|---|

| Structural Steels | SS400 | ○ |

| Carbon Steels | S45C / S50C | ○ |

| Hardened Alloy Steels | SCr / NAK | ○ |

| Mold Steels (Hardened) | 25–40 HRC | ○ |

| Hardened Steels | 40–50 HRC / 50–65 HRC | ○ |

| Stainless Steels | SUS304 / SUS316 / SUS420 | ○ |

| Ti/Ni Alloys | — | ○ |

| Cast Irons | FCD / FC | ○ |

| Aluminum Alloys | AC / ADC | ○ |

| Copper Alloys | Cu | ○ |

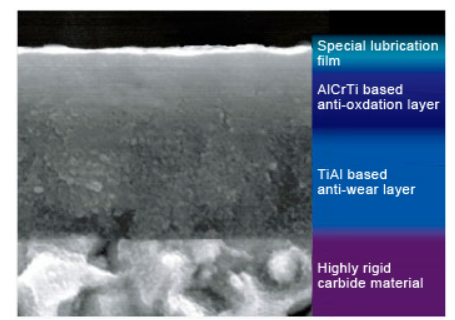

AQUA EX Coating

●Improved resistance to oxidation. heat and wear

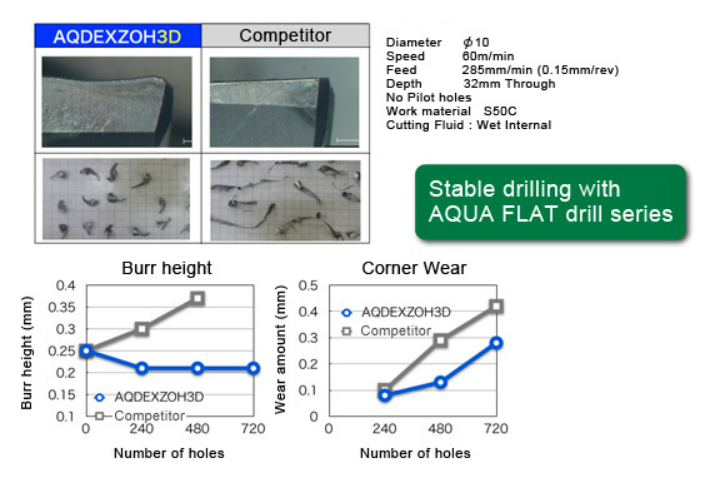

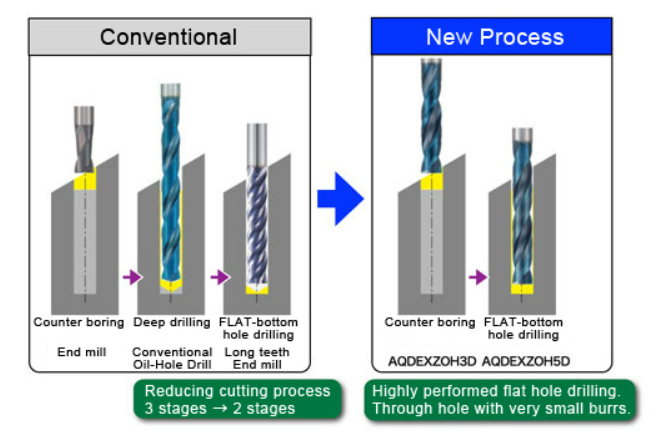

Deep hole drilling with AQUA FLAT Series

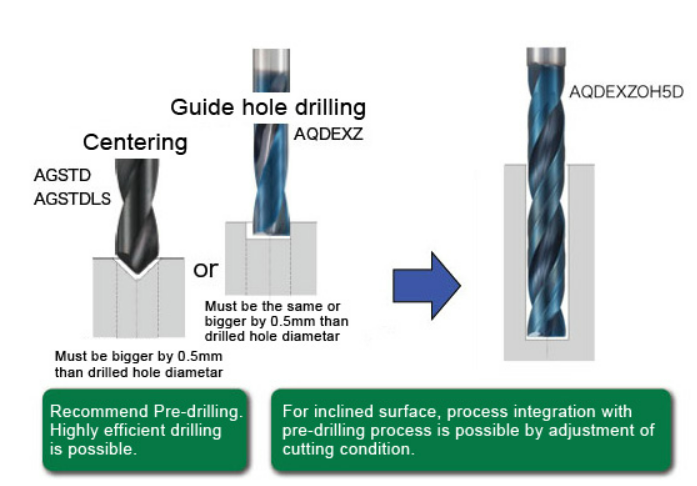

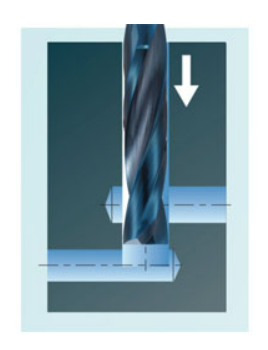

5D FLAT Oil Hole drilling on slope surface

Suitable for cross hole drilling in a deep work position

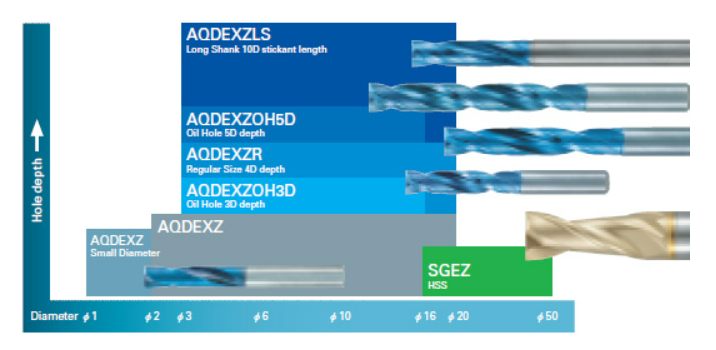

AQUA Drill EX Flat lineup

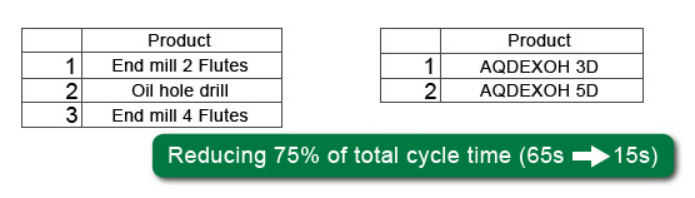

Performance

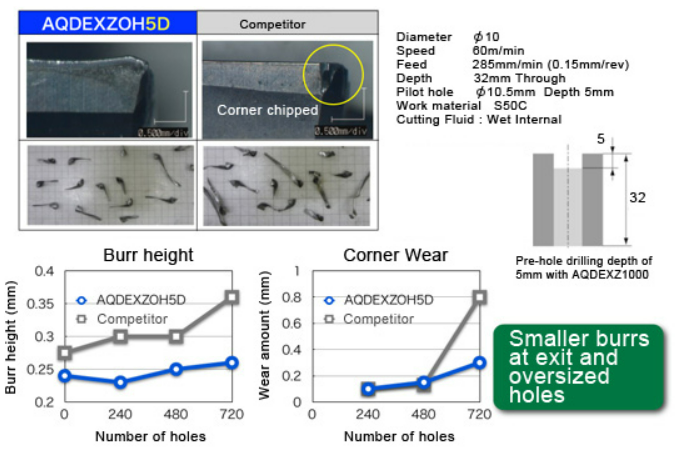

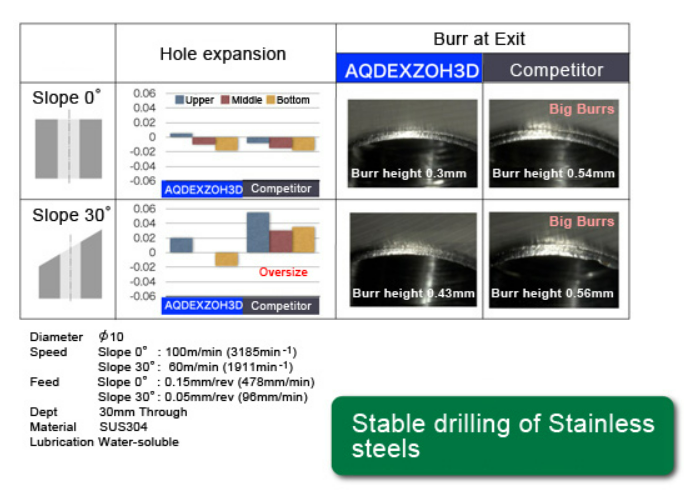

5D FLAT Oil Hole drilling on slope surface

| Process | Product | Size | Slope | Work Material | Depth | Cutting Speed | Feed Rate | Lubrication |

|---|---|---|---|---|---|---|---|---|

| Conventional 1 | End mill 2 Flutes | 30° | — | — | — | 50 mm/min (1592 min⁻¹) | 50 mm/min (0.03 mm/rev) 0.1D Step | External |

| Conventional 2 | Oil hole drill | 0° | — | — | 5D | 120 mm/min (3822 min⁻¹) | 955 mm/min (0.25 mm/rev) | Internal |

| Conventional 3 | End mill 4 Flutes | Ø10 | — | S50C | 50 mm blind hole | 50 mm/min (1592 min⁻¹) | 50 mm/min (0.03 mm/rev) | External (Water-soluble) |

| New 1 | AQDEXOH 3D | 30° | — | — | — | 80 mm/min (1011 min⁻¹) | 80 mm/min (0.05 mm/rev) | Internal |

| New 2 | AQDEXOH 5D | 0° | — | — | — | 120 mm/min (3822 min⁻¹) | 955 mm/min (0.25 mm/rev) | Internal |

| — | — | — | — | — | — | — | 100 mm/min (Between 3.5 ~ 5D) | — |

Sequential drilling (45°Slope → Flat surface)

Through Hole Drilling of Stainless steels (SUS304)

Wear comparison after 720 holes drilling

Wear comparison after 720 holes drillingWear and chip comparison after 720 holes drilling