Nachi

Nachi AQUA Drill EX for Nickel Alloy

Manufacturer: NACHI

Product name: AQUA Drill EX for Nickel Alloy

Outline

■AQUA Drill EX for Nickel Alloy

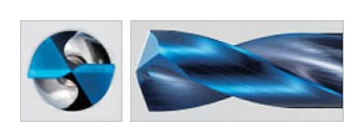

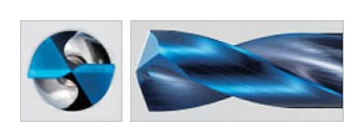

●Coated carbide drill for heat-resistant alloy○ Carbide material is optimal for Nickel Alloys. combining excellent wear resistance with chipping resistance.

Flute geometry combines cutting performance with strength to minimize chipping

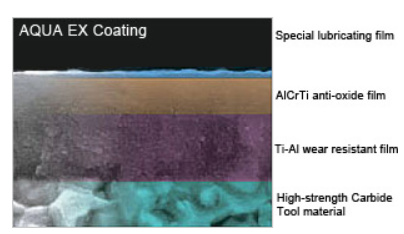

○ Highly lubricant AQUA EX coating improves wear resistance. heat resistance. and prolongs tool life.

Material characteristics of heat-resistant alloy and characteristics required for cutting tools

| Material characteristics of heat resistant alloy | Cutting conditions | Characteristics required for cutting tools for heat resistant alloy |

|---|---|---|

| Highly compatible with tool materials | Poorly finished surface | • Tool materials: Blade break resistance, wear resistance, hardness in hot temperature |

| High heat resistance | Cutting blade chipping | • Tool shape: Blade shape that optimizes sharpness and strength |

| Low thermal conductivity | High cutting temperature | • Coating properties: Materials with low compatibility with work materials, heat resistance, thermal insulating properties, wear resistance, lubrication properties |

| Subject to work hardening | Subject to tool abrasion | — |

| High cutting resistance | — |

Comparison

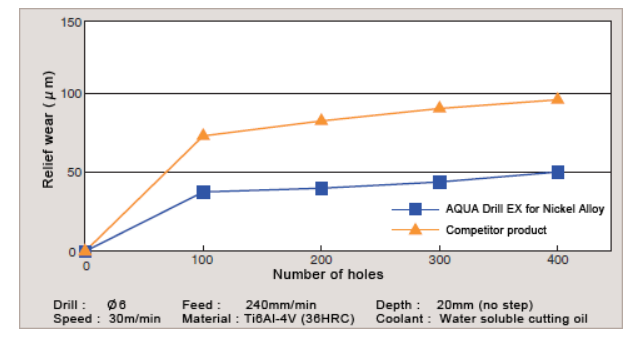

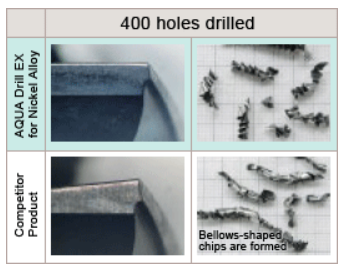

Comparison of Titanium Alloy (Ti6Al-4V) drilling