Nachi

Nachi Diamond Coated Drill

Manufacturer: Nachi-fujikoshi corp

Model: Diamond Coated

Outline

Diamond coating

Powder HSS with SG Coating and the tool life is 2-3 times of conventional drills.

Long tool life

The tool life is 10 times of conventional carbide drill in drilling high silicon aluminum

Precision

It is possible to acquire excellent surface roughness

Series

Diamond Coated Drill

Diamond Coated FF Drill

Features

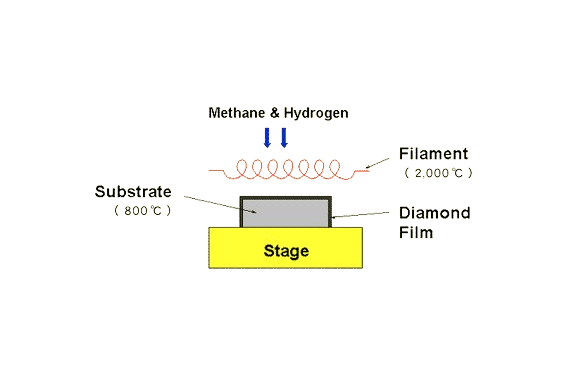

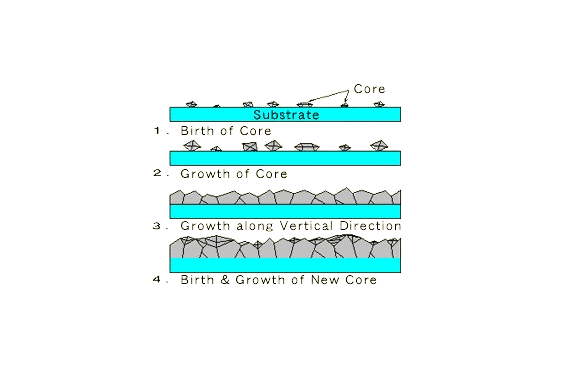

Mechanism of Diamond Coating

Growth Process of Diamond Film Growth process of Diamond film is called as Volmer-Weber type and generally increase its thickness by birth and growth of core repeatedly.

Growth process of Diamond film is called as Volmer-Weber type and generally increase its thickness by birth and growth of core repeatedly.

100% pure diamond coating Applicable on unique cutting edge Applicable on Micro tool

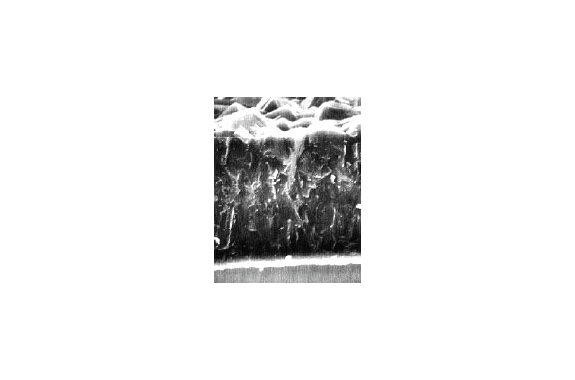

Cross section photo of diamond film

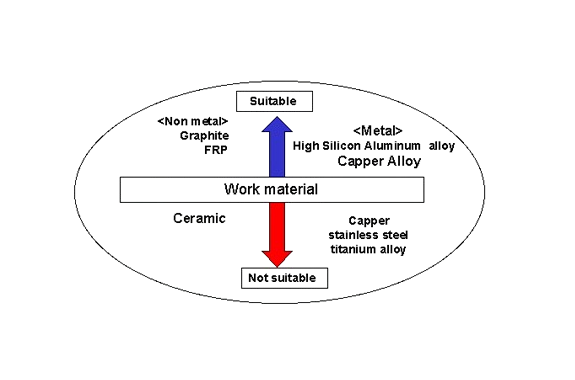

Work materials of Diamond Coated tools

Performance

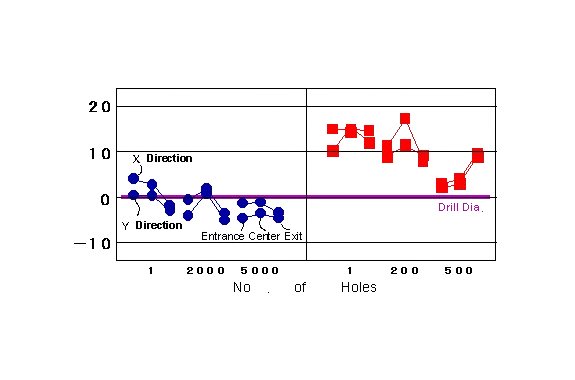

Comparison of Drilling accuracy

Cutting Conditions

Drill Diameter : 3.0

Feed : 0.1mm/rev

Material: AS390

Depth: 10mm

Through Hole (Al-17%Si Alloy)

Coolant : Emulsion Speed: 80m/min

Machine : Vertical MC

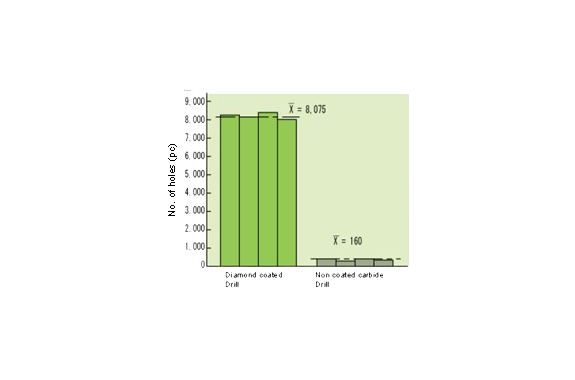

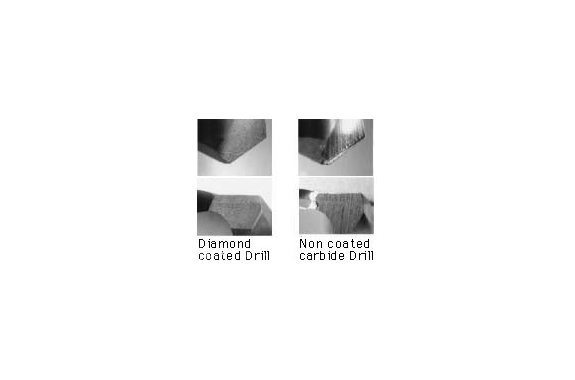

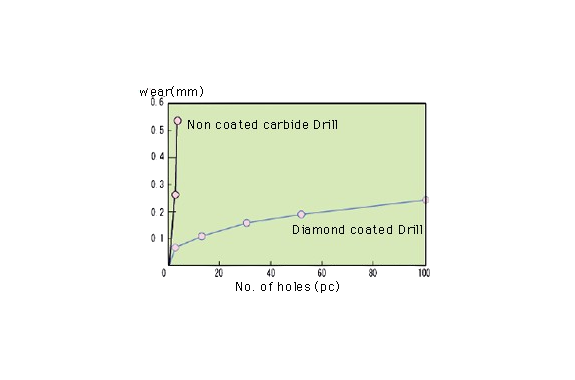

Performance of drilling High silicone

Conditions

ConditionsDrill : 6mm

Speed : 800m/min

Feed : 0.20mm/rev

Depth : 20mm

Through Material : AS390

Coolant : Emulsion

Performance of drilling MMC

Performance of drilling MMC

Examples

| Drill Diameter | Material | Comparison of Tool Life | Drilling Condition | |

|---|---|---|---|---|

| 2.5 | ADC12 (Al–12%SiAlloy) | 20,000 Holes | 258,000 Holes | Rotation: 20,000 min⁻¹ Feed: 0.08 mm/rev Coolant: Emulsion |

| 6.0 | A390 (Al–17%SiAlloy) | 100 Holes | 2,300 Holes | Rotation: 8,000 min⁻¹ Feed: 0.1 mm/rev Coolant: Emulsion |

| 3.0 | GFRP | 3,000 Holes | 30,000 Holes | Rotation: 40,000 min⁻¹ Feed: 0.013 mm/rev Coolant: Dry |

| 1.5 | Pre-Sintered WC–Ceramics | 100 Holes | 14,000 Holes | Rotation: 1,000 min⁻¹ Feed: 0.01 mm/rev Coolant: Dry |

| 2.0 | Pre-Sintered Al₂O₃–Ceramics | Half Day to 3 days | More than 3 months | Rotation: 3,300 min⁻¹ Feed: 0.003 mm/rev Coolant: Dry |