Nachi

Nachi SG Spiral Taps

Manufacturer: Nachi-fujikoshi corp

Model: SG Spiral

Features

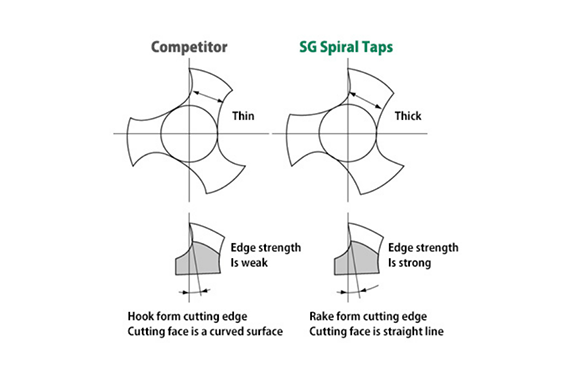

It is hard to be broken by high rigidity flute shape design

Sectional shape Comparison of the breaking torsion torque

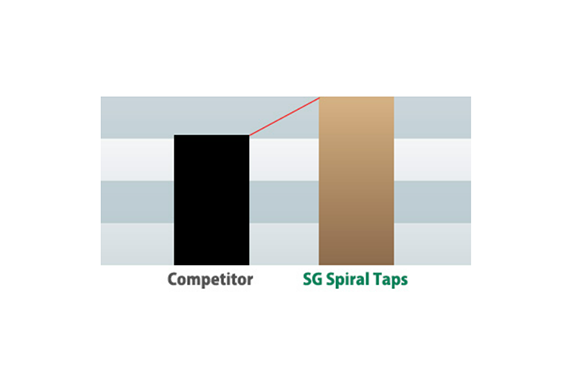

Comparison of the breaking torsion torque

The breaking torque of SGSP is 30% bigger than competitor. SGSP hardly breaks

SG Spiral Taps have wide width of land. and large cross section. Rigidity of stress concentration part is high. the breaking torque is big. so hardly breaks.

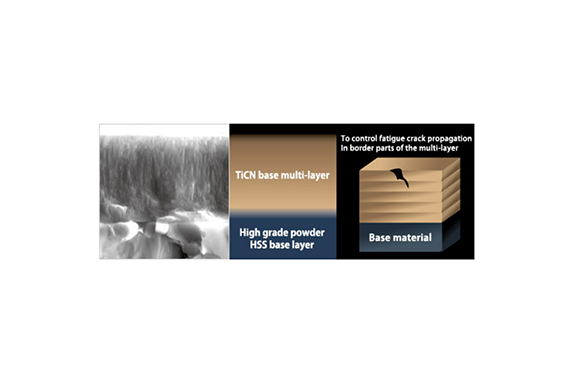

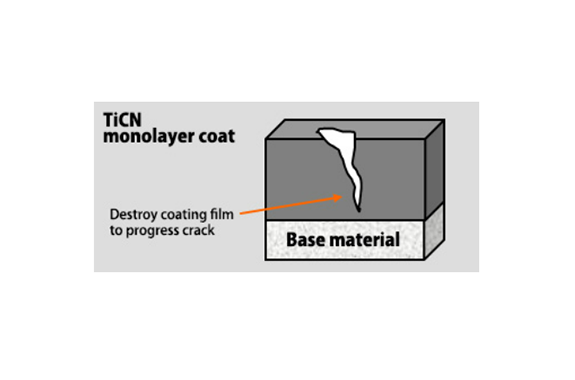

Cross section structure of SG coating

SG coating is dense quality film for specific use of tap Improve wear resistance and toughness by using fine multilayer film

Performance

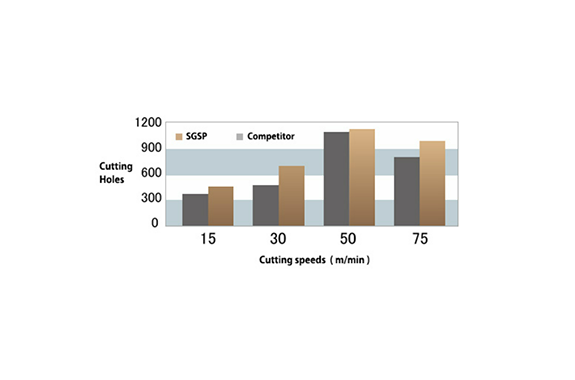

No matter what cutting speeds. stable cutting screw threads and long tool life

Comparison of cutting holes by cutting speeds

Thread size: M6 × 1

Work material: S50C (180HB)

Thread depth: 12mm

Drill hole Dia.: Ø5.1

Drill hole depth: 20mm (Blind holes)

Feed: Synchronized feed

Holder: Collet chuck

Machine: Vertical machining center

Cutting fluid: Water-soluble cutting fluid (External coolant)

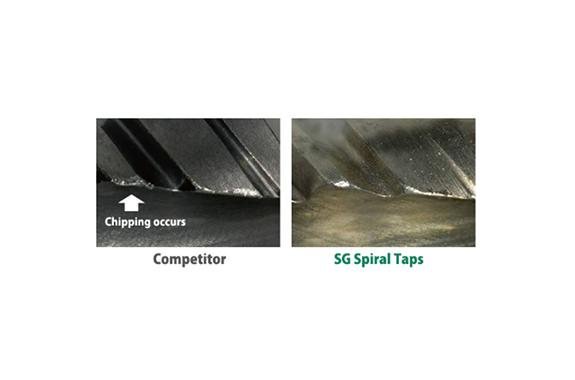

Comparison of wear after cutting 210 holes by cutting speed Vc30

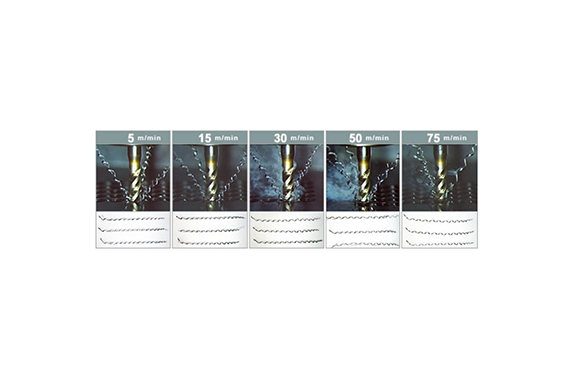

Cutting scenes and chips by every cutting speeds Corresponding to every work materials

Corresponding to every work materials

Cutting scenes and chips by every work material

Stable chips and cutting scene from Structural Steels to Stainless Steels. Aluminum Alloys Corresponding to every work materials

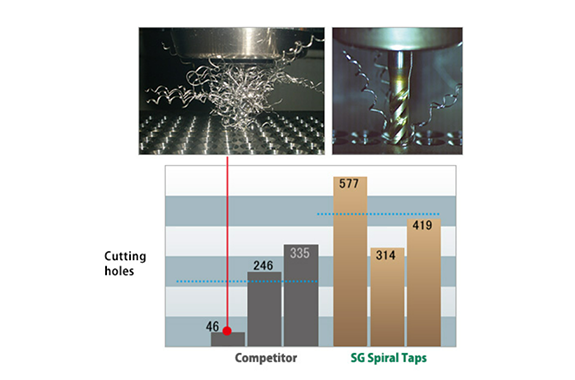

Long tool life with Stainless Steels

Comparison of cutting holes of SUS304

Thread size: M6 × 1

Work material: SUS304

Thread depth: 12mm

Cutting speed: 8m/min

Drill hole Dia.: Ø5.1

Drill hole depth: 19mm (Through holes)

Feed: Synchronized feed

Holder: Collet chuck

Machine: Vertical machining center

Cutting fluid: Water-soluble cutting fluid (External coolant)