Nachi

Nachi GSX MILL VL Roughing

Manufacturer: Nachi-fujikoshi corp

Model: GSX MILL VL

Outline

Carbide roughing end mill ideally suited to high-efficiency pre-finish machining

End mill featuring unequal spacing of teeth and variable leads to suppress chattering vibration Pre-finish model added to the GSX MILL VL series

Optimizes cutting-edge design and nick shape for enhanced chipping resistance and high-efficiency machining

Supports a wide range of machining

Demonstrates outstanding cutting performance in any application from grooving to pocket machining

Lineup

Ø4-Ø20 (13 sizes)

Features

Features a design optimized for unequal spacing of teeth and variable leads to improve chipping resistance and enable high-efficiency machining

Nick shape

Suitable for unequal spacing of teeth and variable leads Excellent chipping resistance

Flute geometry

Stiffness to withstand heavy cutting Chip evacuation performance that enables pocket machining Applicable work materials

Applicable work materials

| Product | Low-Carbon Steels SS400, S10C | Carbon Steels S45C, SCM440 | Pre-Hardened Steels SUJ, NAK | Tempered Steels SKD, SKH | Hardened Steels 40–65HRC | Stainless Steels SUS304 | Titanium / Ni Alloys |

|---|---|---|---|---|---|---|---|

| Hardness (approx.) | ~150HB | ~225HB | ~275HB | 30–40HRC | 40–65HRC | — | — |

| AGPSD | ◎ | ◎ | ◎ | ○ | ○ | ○ | ○ |

| AGPLSD | ◎ | ◎ | ◎ | ○ | ○ | ○ | ○ |

| AGPMSD | ◎ | ◎ | ○ | ○ | ○ | ○ | ○ |

| AGPMLSD | ◎ | ◎ | ○ | ○ | ○ | ○ | ○ |

◎: Optimal

○: Acceptable

×: Not Recommended

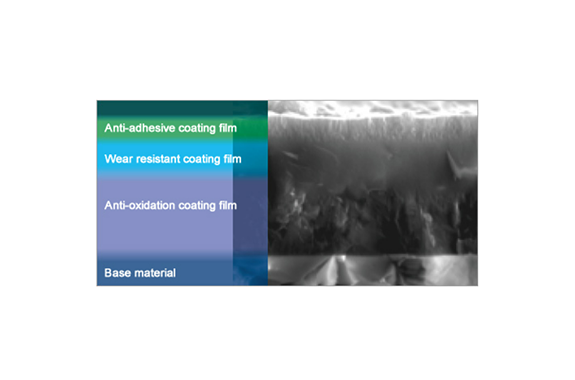

GSX II coating

Achieves excellent heat resistance with enhanced oxidation resistance and heat dissipation.

Features a new layered structure for high hardness.

Optimizes the crystal structure of the film for increased resistance to wear and adhesion.

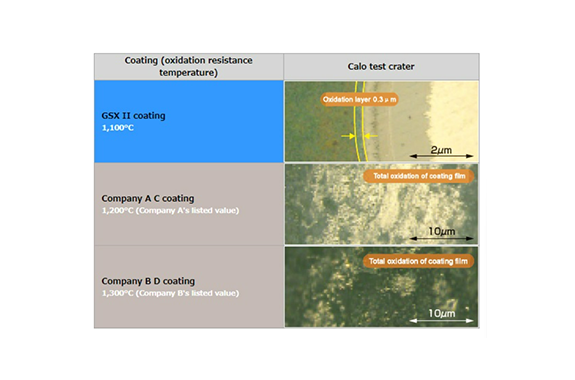

Heat resistance far superior to competitors

Oxidation resistance evaluation (calo test crater after being held for 1 hour in the atmosphere at 1.100°C)

Oxidation resistance tests conducted under NACHI standards showed GSX II coating limits oxidation to 0.3µm from the surface. whereas coating products of competitors resulted in total oxidation of the coating layer.

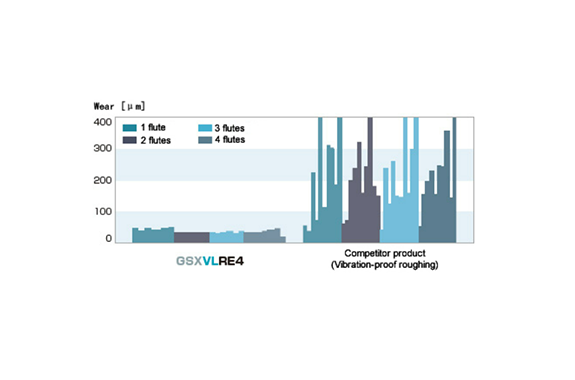

Performance

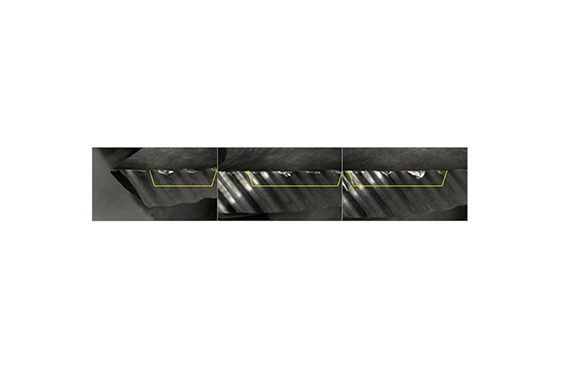

Improves chipping resistance for a longer tool life

Comparison of wear after grooving 10m with S50C

Tool: GSXVLRE4 Ø10

Speed: 130 m/min

Feed: 1000 mm/min

0.06 mm/tooth

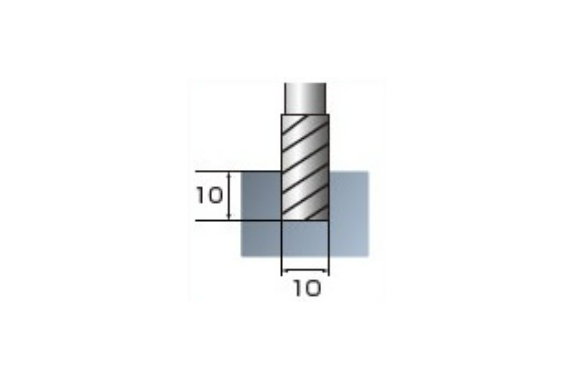

Depth of cut: ap 10 mm grooving

Work material: S50C

Coolant: Emulsion

Cutting length: 10 m

GSXVLRE4

GSXVLRE4 is capable of continuous machining with no chipping

Competitor products

Chipping occurs frequently