Nachi

Nachi GSX MILL Ball Carbide End Mills

Manufacturer: Nachi-fujikoshi corp

Model: GSX MILL Ball

Outline

Ball end mill that covers from common applications to high-speed applications

Smooth streamlined ball nose-shaped edge improves chip removal.

High-speed milling is possible for raw materials. stainless steel. and hardened steels.

GSX II coating with superior heat. wear and adhesion resistance to achieve long tool life.

GSX II coating

With outstanding heat, wear, and adhesion resistance, GSX II coating significantly prolongs tool durability.

| Code | Structural Steels (SS400) | Carbon Steels (S45C, S50C) | Hardened Steels Alloy Steels (SGr, NAK) | 25–40HRC | 40–50HRC | 50–65HRC | Stainless Steels (SUS304, SUS316) | SUS420 | Titanium/Nickel Alloys | Cast Irons (FCD/FC) |

|---|---|---|---|---|---|---|---|---|---|---|

| GSXB | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ○ | — | ◎ |

Features

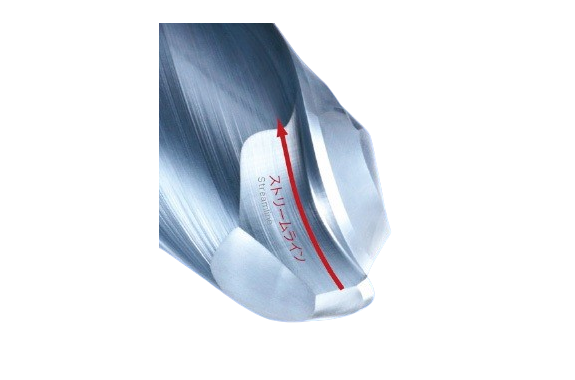

Streamlined shape

Smooth streamlined ball nose-shaped edge R

Smooth streamlined ball nose-shaped edge R

educes cutting resistance

Improves chip removal Suitable wide range of work materials.From general-purpose to ultra high speed milling.

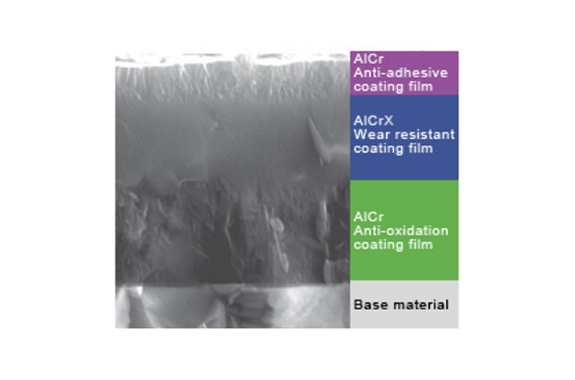

GSX-II Coating

Excellent heat resistance

Achieve high heat Resistance with Al-rich composition. Multi layer structure

Multi layer structure

High hardness of coating in according to multi layer structure with AlCr and AlCrX.

Crystal structure

Great wear and resistance with optimum crystal structure.

Evaluation of oxidation resistance

Status of coating films after keeping with 1.100°C in the air after 1 hour.

Performance

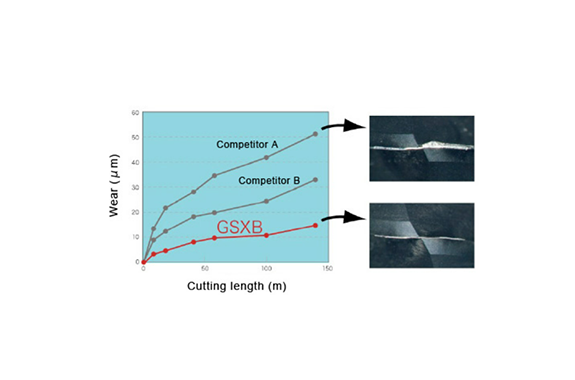

Wear comparison with SKD11 (raw material) Cutting tool: R1.5

Cutting tool: R1.5

Cutting Speed: 180 m/min

Feed: 3,000 mm/min (0.079 mm/tooth)

Coolant: Air blow

Depth: ap = 0.06 mm

Pf = 0.15 mm

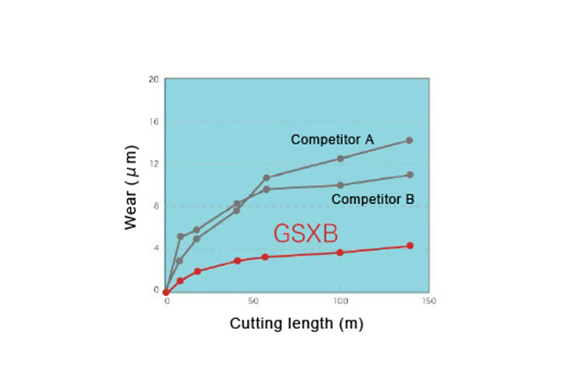

Wear comparison with SKD61 (53HRC) Cutting tool: R1

Cutting tool: R1

Cutting Speed: 119 m/min

Feed: 1,700 mm/min (0.045 mm/tooth)

Coolant: Air blow

Depth: ap = 0.04 mm

Pf = 0.10 m