Nachi

Nachi GS MILL Hard Carbide End Mills

Manufacturer: Nachi-fujikoshi corp

Model: GS MILL

Outline

Super high speed milling

Newly developed ultra aluminum rich Al-Ti-Cr multi-layered “GS

Hard Coat” allows super high speed milling up to 800m/min.

Unique geometry improves chip removal and tool rigidity.

Improved durability due to new ultrafine particle. cemented carbide.

Long tool life

Ultra micro grain low-cobalt carbide with high hardness improves tool material strength and curtails micro-plastic deformation that can occur at very high speeds. The result is better durability.

Features and Performance

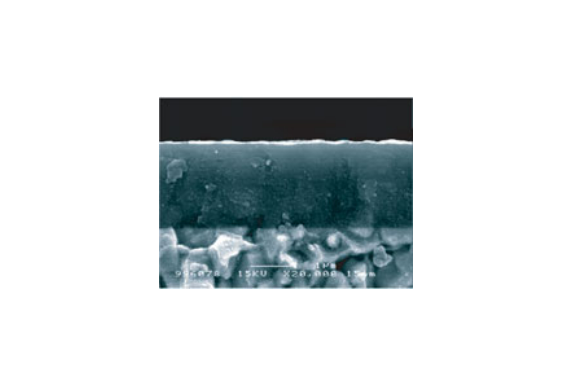

GS Hard Coat

Top layered film consists of newly developed ultra aluminum rich Al-Ti-Cr coating. with 3 times better oxidation resistance at 1.100 deg Centigrade.

Improved heat and wear resistance at ultra high-speed milling

AlCrTi oxidation prevention layer

Microstructure provides higher film strength

Ti-Al wear resistance layer

High-strength Carbide material

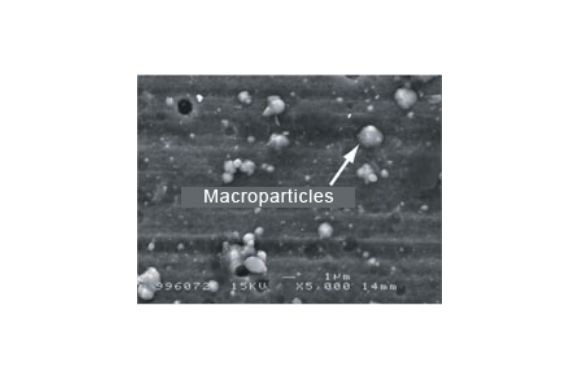

Fewer macroparticles on film surface result in improved smoothness

Reduced abrasion and better deposition resistance

Improved wear and adhesion resistance

GS Hard Coating

Conventional coating

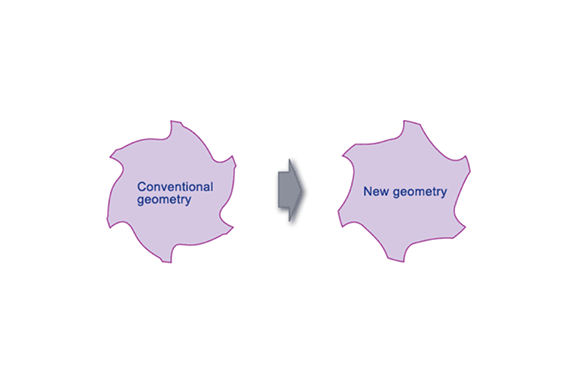

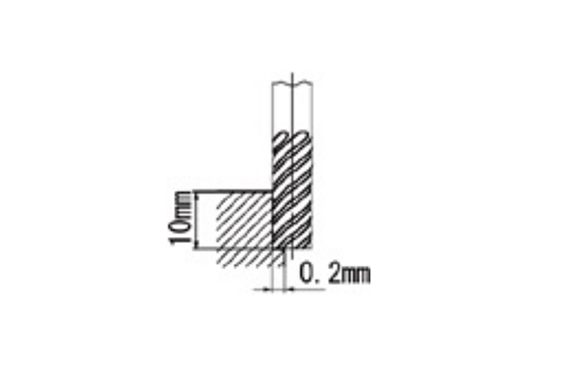

New geometry

Smoothly curved flute geometry improves chip removal.

Wide land improves tool regidity

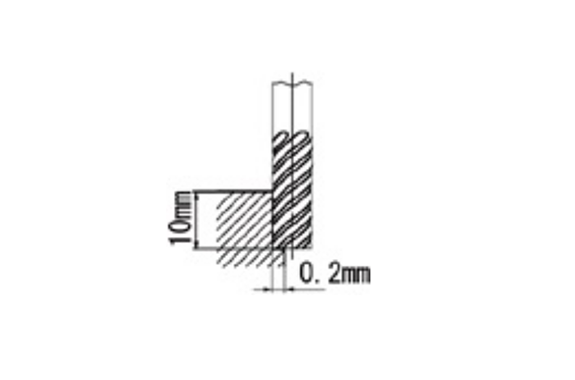

Ext. Diameter 10 (6 Flutes) : SKD61 (53HRC)

Cutting speed 800 m/min

Wear less than 1/3

Ext. Diameter 10 : SKD11 (60HRC)

Milling condition

Milling conditionTool: GSH6100SF

Speed: 800m/min (25.000min-1)

Feed : 10.500mm/min (0.07mm/tooth)

Material : SKD61 (53HRC)

Coolant: Air blow Cutting length : 75m

Milling condition

Tool: GSH6100SF

Speed: 70m/min (2.230min-1)

Feed: 900mm/min (0.067mm/tooth)

Material: SKD11 (60HRC)

Coolant: Air blow

Cutting length : 70m