Nachi

Nachi GP/SP Hob Hyper DuAl Gear Cutters

Manufacturer: Nachi-fujikoshi corp

Model: GP/SP Hob

Features

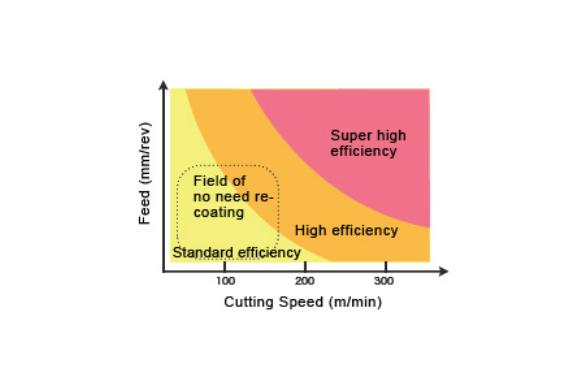

Selection of hob to suit the application

| Type | Wet Hobbing (Oil, Emulsion) | Dry Hobbing | |||

|---|---|---|---|---|---|

| Standard Efficiency | High Efficiency | Super High Efficiency | High Efficiency | Super High Efficiency | |

| Re-grinding + Re-coating (Full coating) | Hyper DuAl GP | Hyper DuAl GP | Hyper DuAl SP | ||

| Without re-coating (No coating on cutting face) | DuAl VX | DuAl EX | |||

Hob coating performance

| Property | DuAl VX | DuAl EX | Hyper DuAl GP | Hyper Dual SP |

|---|---|---|---|---|

| Wear resistance | ◯ | ◎ | ◎ | ◎ |

| Toughness | ◯ | ◯ | ◎ | ◯ |

| Heat resistance | △ | ◯ | ◎ | ◎ |

| Stability | ◎ | ◎ | ◎ | ◎ |

| Coolant | Wet & Dry | Wet & Dry | Efficient Wet & Dry | Super-efficient Dry |

| Hardness of coating | 2300 ~ 2500 | 2300 ~ 2500 | 2400 ~ 2600 | 2500 ~ 2700 |

| Heat resistance temp. | 850°C | 950°C | 1100°C | 1150°C |

Ideal selection of coating to suit the wear condition.

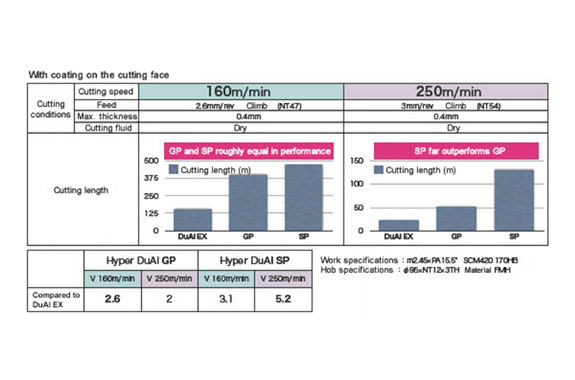

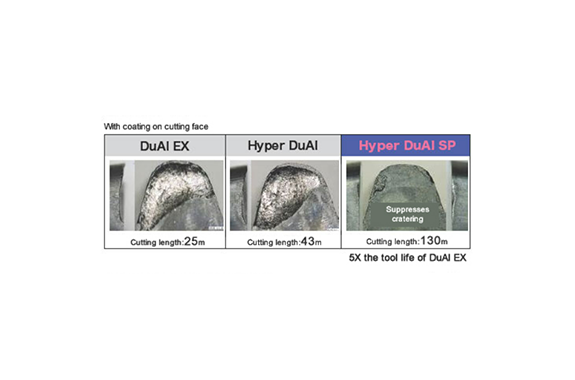

Performance comparison of Hyper DuAl GP/SP

Hyper DuAl GP: Extended tool life under conventional hobbing conditions.

Hyper DuAl SP: Outstanding performance under harsh conditions.

In some cutting areas, the performance of Hyper DuAl SP may be compromised under wet or conventional hobbing conditions.

Performance

Ultra-high speed hobbing with Hyper DuAl SP Hob Work Spec.: m2.9 × PA16° × NT50, SCM420

Work Spec.: m2.9 × PA16° × NT50, SCM420

Hob Spec.: φ95 × NT12 × 3TH

Material: FMH

Conditions: V = 250, 300 m/min, f = 3.0 mm/rev, Climb, dry hobbing (Chip thickness: 0.4 mm)

Excellent stability in ultra-high-speed hobbing (250 m/min or more) Advantage with work materials prone to cratering and wear

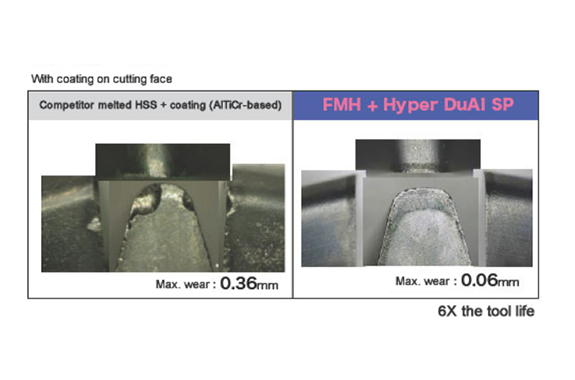

Hobbing of difficult-to-machine materials with Hyper DuAl SP Hob

Work Spec.: m1.78 × PA14.5° × NT80 × HA21° RH S45C 250HB

Face Width: 27 mm

Hob Spec.: φ70 × NT12 × 3TH

Material: FMH

Conditions: V = 110, 148 m/min, f = 3.0, 2.8 mm/rev, Climb, dry hobbing

No. of Cuts: 700

Superior wear resistance and stability with difficult-to-machine materials

Advantage with work materials prone to cratering and wear

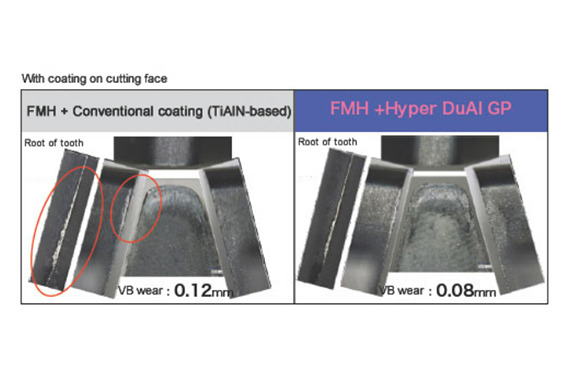

Dry hobbing with Hyper DuAl GP Hob

Work spec.: m1.75 × PA17.5° × NT43 × HA34° LH SCr420H

Hob spec.: φ85 × NT16 × 4TH

Material: FMH

Conditions: V = 150 m/min, f = 2.0 mm/rev, Climb, dry hobbing

No. of cuts: 1,900

Extends tool life 1.5 times with superior coating

Suppresses VB wear of the root of the gear tooth by increasing adhesion