Nachi

Nachi Skiving Cutter

Manufacturer: Nachi-fujikoshi corp

Features

Optimal tool design

We utilize gear processing technology and tool design technology to implement analyses of cutting mechanisms in order to achieve higher precision and longer tool life.

Surface treatment tailored to skiving processing

We add surface modification to film component design and optimization of the film formation process to establish the surface treatment technologies necessary for skiving processing.

Performance

Comparison with competitor

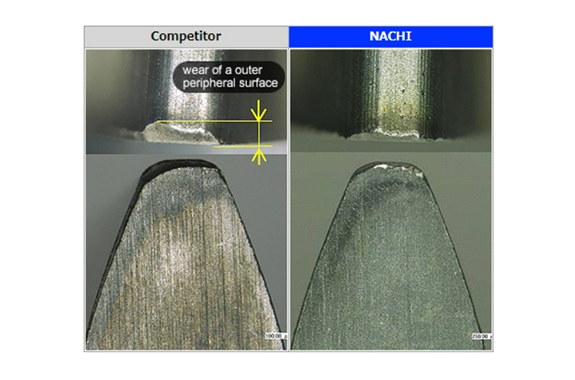

Damage comparison of cutter

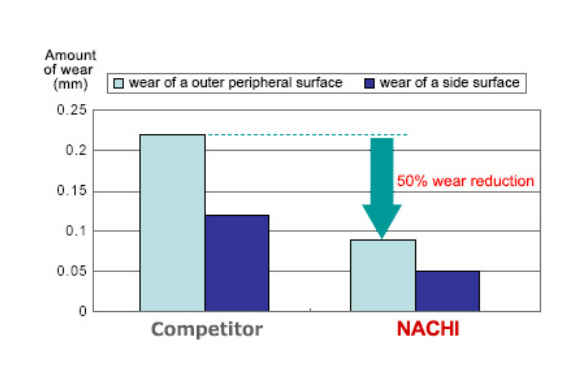

Cutter abrasion amount comparison

NACHI Skiving Cutter Compared to the products of other companies, the damage is less and the cutter service life is approximately twice as long.

Processing specifications

| Workpiece Spec | Cutter Spec | Machining Condition |

|---|---|---|

| Module × Pressure Angle m1.2 × PA18° | No. of Teeth 50 | Cutter Rotation 1st pass / 2nd pass 1410 / 1410 min⁻¹ |

| Tooth Direction Internal Teeth | Helix Angle 5° LH | Cutting Speed 100 / 100 m/min |

| Helix Direction 17° RH | Material FAX55 | Feed Rate 0.1 / 0.1 mm/rev |

| Material SCM415 | Coating Hyper DuAl SP | Cutting Fluid Oil |

| Face Width 22 mm | Coating Side (Tooth face) | No. of Workpieces 200 pcs |