Miura

Miura Flue Gas Desulfurization Equipment For Power Generation Facilities

Manufacturer: Miura Chemical Equipment Co., Ltd.

With air pollution now a social issue, harmful gases such as SOx (sulfur oxides), NOx (nitrogen oxides), and HCl (hydrogen chloride gas) emitted from business establishments are subject to strict regulations.

As an “exhaust gas treatment expert,” we have accumulated extensive know-how and a proven track record of delivery over the past 40 years, and we offer custom design, installation, and after-sales service for exhaust gas treatment equipment that meets increasingly sophisticated needs.

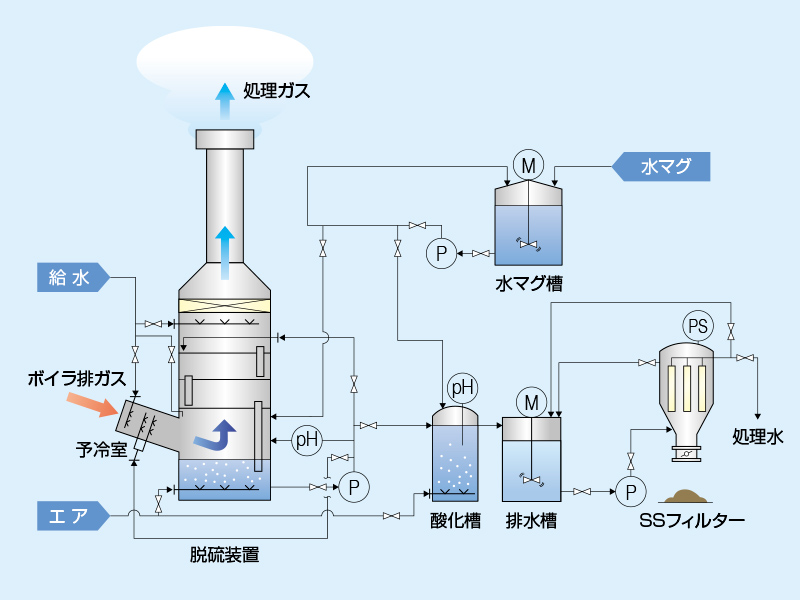

Flue gas desulfurization equipment for power generation facilities

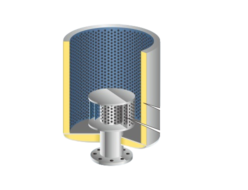

Exhaust gases from power generation boilers, diesel engines, and other sources contain SOx (sulfur oxides), and the system removes these components by bringing them into contact with an alkaline agent. First, the system cools the high-temperature, harmful gases in a pre-cooling chamber, and then it sends them into the desulfurization unit. Inside the desulfurization tower, the gases meet the circulating fluid supplied from above onto trays (perforated plates), so the gas and liquid contact each other intensively and the system absorbs and removes SOx efficiently.

To control the concentration of reactive salts, the operator continuously extracts part of the circulating fluid from the desulfurization unit. This circulating fluid contains many solids, such as magnesium sulfite and unburned carbon, which act as COD components. Therefore, the system first sends the fluid to the oxidation tank and reduces COD efficiently there, and then it passes the fluid through an SS filter to separate the solids before the operator finally discharges the treated liquid.