Miura

Miura Denitration Equipment

Manufacturer: Miura Chemical Equipment Co., Ltd.

Denitration equipment

Boilers, diesel engines, gas turbines, and other combustion equipment emit NOx (nitrogen oxides), and these nitrogen oxides then cause acid rain and also promote the formation of photochemical smog. Selective catalytic reduction (SCR) is now the mainstream NOx reduction method due to its economy and reliability. At MIURA, we can propose optimal designs using the know-how we have gained from our extensive delivery track record.

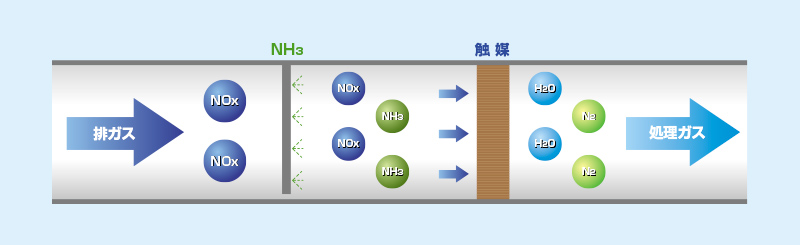

Principle

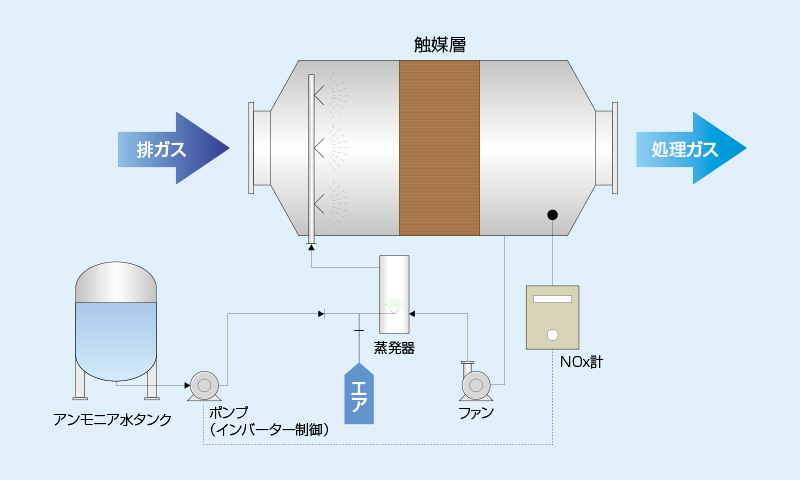

Denitration equipment using ammonia water

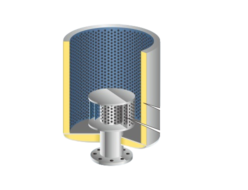

The denitration equipment offers both vertical and horizontal installation options, so the designer can match the layout to the exhaust gas characteristics and the available installation space. In the catalyst layer, the system places a catalyst module that consists of a bundle of 150 × 150 mm honeycomb catalysts.

Next, the operator sprays ammonia water with a two-fluid nozzle, then vaporizes it in an evaporator, and finally mixes it with the exhaust gas immediately before the catalyst layer. In addition, the control system automatically adjusts the injection rate of ammonia water according to the NOx concentration measured at the outlet, so the equipment maintains efficient denitration performance.

Application/Method

NH 3 (ammonia) or urea water is added as a reducing agent to exhaust gas containing NOx , which is then passed through a catalyst layer where it is reduced to harmless N 2 (nitrogen).

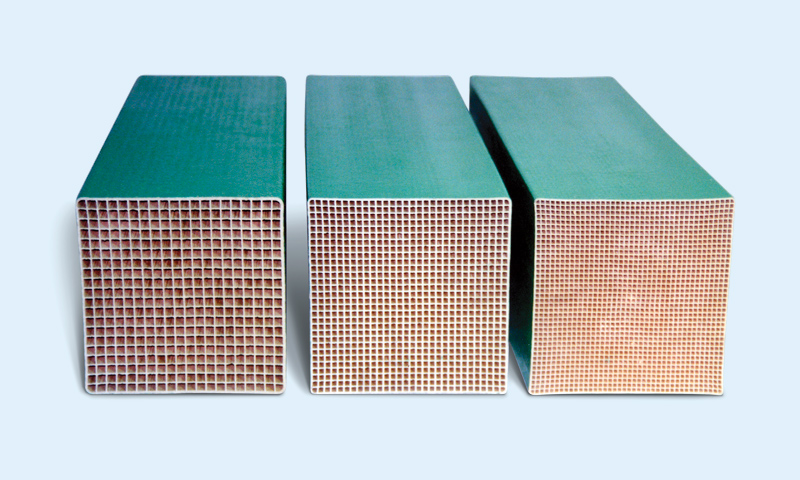

Denitrification catalyst

We select the most suitable catalyst depending on the exhaust gas properties.

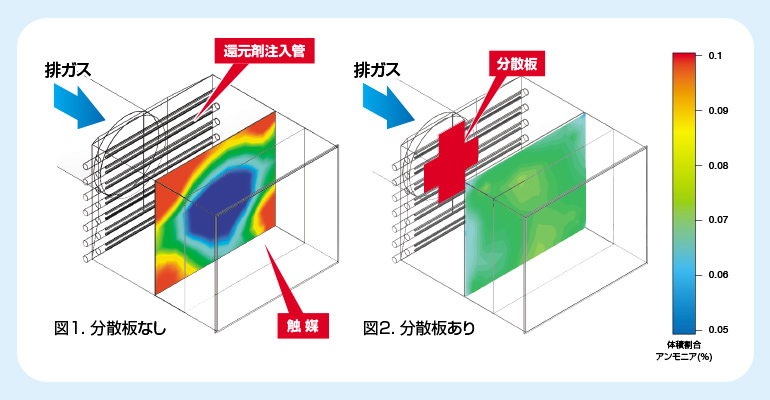

CFD (fluid analysis)

To maximize performance, it is important to disperse the reducing agent evenly in the exhaust gas. At Miura, we can confirm and examine dispersion using CFD.