Nitolex Corporation

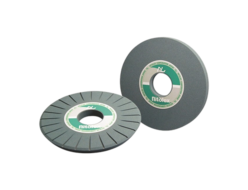

Nitolex Hybrix Wheels

Manufacturer: Nitolex Corporation

Model:Hybrix

Features

Glass grinding wheel

New diamond wheels modified Uplas bond, a composite of special ceramic bond and metal bond, specially designed for ceramics grinding such as quartz glass and soda glass.

Characteristics of Hybrix Wheels

When glass grinding, there are many ploblems they are rough surface finish and large scratches. They are caused sharpness decreases and wheel loading. There for this leads to increased dressing time and greatly decreases the work efficiency and wheel life. The new Uplas bond reduces wheel loading and keeps the wheel sharpness for longer to vastly reduce the dressing time and eliminate dressing completely, greatly improving work efficiency and stabilizing surface quality.

Applications / Types of Bond

| Bond Type | Grinding Type | Grain Size |

|---|---|---|

| KUB75G | Rough grinding | #60~325 |

| UB75G | Medium grinding | #400~2000 |

| UB73G | Finishing grinding | #1200~2500 |

* Other grain sizes are also possible (please apply to us)

Example Applications

Quartz glass

Vertical spindle surface grinder with round table(Sanshin Seiki SPG-750)

Wet (Water solution)

Allowance: 0.3mm Flatness: 5µ

Surface quality: Microscope (visual inspection)

Wheel speed: 15 m/s Work speed: 1 m/min

Depth of cut: 0.001 mm/s

Wheel: SD 1000 O UB73G 6A2M 350D x 75T x 250H x 5W x 5X

| Hybrix | Conv. Resin #800 | |

|---|---|---|

| Sharpness | Excellent (process as set) | Not completely ground |

| Surface finish | good | Unsatisfactory |

Soda glass

Vertical spindle surface grinder with round table (Ichikawa Grinder Mfg.)

Wet (Water solution)

Allowance: 0.1mm Flatness: 1µ Surface finish : Ra 0.4

Wheel speed: 10 m/s

Rough grinding Depth of cut: 20µ

Precision grinding Depth of cut: 4µ

Wheel: SD 1500 P UB73G 6A2M 250D x 60T x 80H x 10W x 10X

| Hybrix | Conv. Resin #1200 | |

|---|---|---|

| Sharpness | Excellent without wheel loading | — |

| Work quality | Flatness: good Surface finish: good Post processing good | — |

| Dressing | Not required | 2 times/day |

| Wheel life | 1.2 times longer | — |