Nitolex Corporation

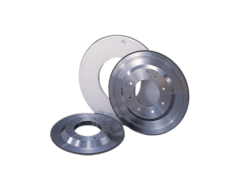

Nitolex Uplas Wheels

Manufacturer: Nitolex Corporation

Model: Uplas

Features

New Bond Wheels

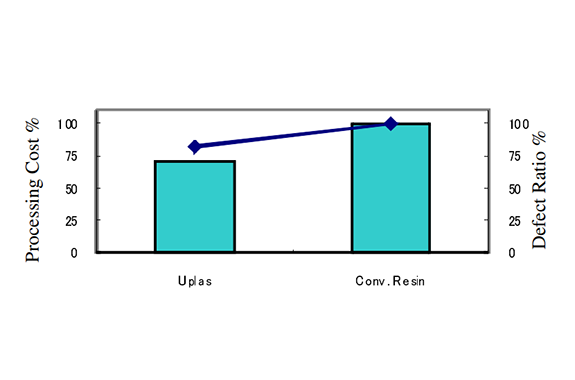

Uplas wheels are high-performance wheels using a compound bond manufactured by sintering special ceramic and metal bonds with our original technology. Uplas wheels take advantage of extremely sharp ceramics bond and a metal bond with extended wheel life.

Characteristics of Uplas Bond

High performance

Excellent sharpness and longer wheel life are realized by the strong abrasive retention and moderate fructure of the bond.

Wide rang of applications

The bond strength can be adjusted over a wide range to adapt the wheel to a variety of materials and grinding conditions.

Easily Truing/Dressing

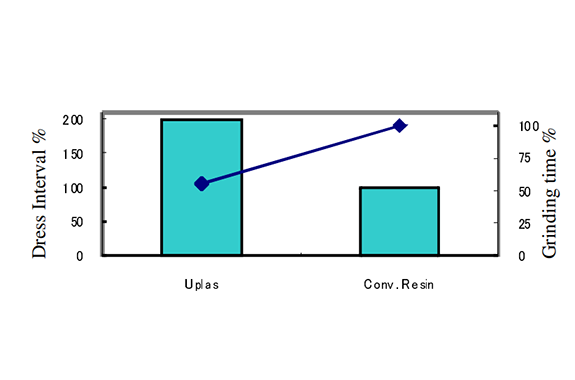

Truing with WA or GC wheels is twice as efficient and dressing with them is five or more times as efficient as with resin bonded wheels, increasing production capacity

Types of Bond

| Materials | Bonds | |

| High-speed steel, sintered alloy, etc. | UB75 The sharpness and wheel life are maximized with grain sizes between #60 and #325. | FUB75 A modified version of UP75 with improved sharpness. Especially useful for harder materials. |

Application

High-speed steel

NC tool grinder Makino CNR-60

Creep grinding – wet (straight oil)

Wheel speed: 24 m/s

Work speed: 20 mm/min

Depth of cut: 4 mm

Wheel: CBN 140 R 125

FUB75

1F1 75D x 12T x 20H x 10X

Types of Bond

| Materials | Bonds | Bonds |

| Cemented carbide Cermet | UB75 The sharpness and wheel life are maximized with finer grain sizes between #270 and #1000. | RUB75 A modified version of UB75 bond with improved sharpness at #400 or coarser. |

| PCD/PCBN | UB73 Excellent surface quality and average performance of metal and vitrified bonds are obtained with grain sizes between #400 and #2500. | |

| Alumina, silicon nitride, silicon carbide, etc. | KUB75 A bond specialized for ceramic materials at grain sizes between #60 and #1000, and ensuring excellent sharpness and wheel life, especially for resin bonds. | |

| Others | CF50 Specialized for tungsten | UF50 · UB55 Supporting individual special applications |

Applications

Cemented Carbide

Mitsubishi CNC cylindrical grinder A32-P

Cylindrical grinding

Wet (oil)

Improved stock removal rate 20%

Work diameter:16 mm

Stock Removal: 0.04 mm

Wheel speed: 30 m/s

Work speed: 15 m/min

Feed speed: 330 mm/min

Depth of cut: 20µm

Wheel: SD 800 N 100 UB75

Cermet

| Surface finish | 2S (excellent) |

| Sharpness | Low grinding noise / low chipping |

| Dressing interval | 50 pieces (conventionally 25 pieces) |

Makino C-40 Automatic Wet (water solution)

Creep grinding

Work Chip breaker

Feed speed: 15 mm/min

Depth of cut: 0.5mm

Wheel speed: 28 m/s

Wheel: SD 600 L 100 UB75

1A1 100D x 10T x 20H x 5X

Alumina

Okamoto surface grinder

Wet (water solution) traverse grinding

Wheel speed: 33 m/s

Work speed: 16 m/min

Feed speed: 20 mm/pass

Depth of cut: 10 µm

Wheel: SD 140 T 100 KUB75

1A1R 450D x 40T x 127H x 5X Silicon nitride

Silicon nitride

Centerless grinder Chubu Machinery Works

Wet (water solution)

Wheel speed: 25 m/s Feed speed: 17 mm/min

Depth of cut: 0.5 mm

Wheel: SD 120 T 125 KUB75

9A1 200D x 60T x 32H x 5X