Nitolex Corporation

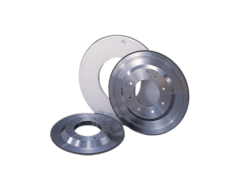

Nitolex Cera Dia Wheels

Manufacturer: Nitolex Corporation

Model:Cera Dia

Features

Cera Dia Wheels

High-performance, porous wheels with diamond abrasive, which has the highest hardness of all materials and ensures excellent sharpness and wear resistance, retained with a rigid, fine ceramic bond.

Increasingly advanced grinding technologies require higher grinding accuracy and greater adaptability to hard-to-grind materials. In addition, there has been a demand for cost reduction through automation and unmanned operation. The Cera Dia wheels make the most of diamond abrasive characteristics to meet those requirements

Characteristics

1.Higher retention force

Our ceramic bond strengthens the chemical bond with diamond grains and keeps them firmly anchored.

2.Sustainable sharpness

The porous structure delivers sharp cutting, high rigidity, and easy dressing, enabling accurate, efficient grinding with minimal distortion or dressing.

3.Adaptable to various materials and conditions

We adjust fillers such as alumina and silica carbonate to match different materials and grinding conditions.

4.All products made to order

We design each wheel to fit the customer’s specific application.

These advantages allow Cera Dia wheels to excel in medium- to fine-finishing, cut overall grinding cost, and support mirror grinding of ferrous metals.

Bond

Engineers select the optimal bond based on the operating conditions.

| Type | Characteristics | Grinding method | Work materials |

|---|---|---|---|

| CRD1 | Standard | Tool, surface, cylindrical, internal, etc. | PCD / PCBN / glass / ceramics Tungsten carbide / combinations of tungsten carbide and steel |

| CRD3 | High-efficiency grinding | Tool, surface, etc. | PCD / PCBN / glass / ceramics |

| CRF1 | Abrasion resistance | Tool, cylindrical, etc. | PCD / PCBN |

| CRF3 | Mirror grinding | Tool, surface | PCD / PCBN / ceramics |

| CRM1 | Soft material grinding | Generic | Aluminum / plastic / ferrite |

| NF02 | High-efficiency NANOFIX | Tool, surface, cylindrical, internal, other | Semiconductor parts / optical parts / glass Tungsten carbide / PCD / etc. |

| NF08 | Super-finishing NANOFIX | — | — |

Concentrations

Generally used concentrations:

| Work materials | Concentration |

|---|---|

| PCD / PCBN | 150 – 200 |

| Ceramics | 75 – 125 |

| Tungsten carbide | 50 – 125 |

| Ferrite / aluminum | 75 – 125 |

| Various kinds of glass | 50 – 125 |

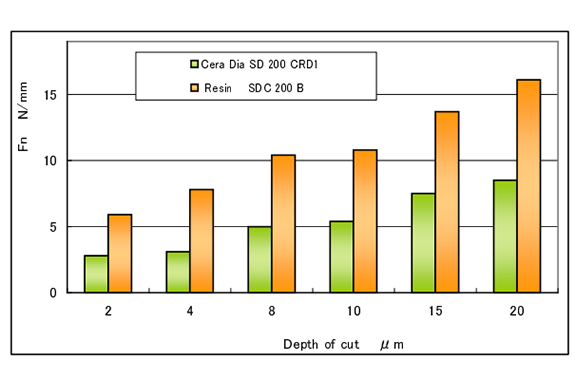

Data

Work material :Silicon Nitride (5% Yttria, 5% Alumina, Weibull coefficient 11.8)

Wheels:

Cera Dia SD 200 concentration: 100 CRD1

Resin SDC 200 concentration 100 B (competitor)

14A1 200D×20T×50.8H×10U×3X

Grinding method: Wet, up cut plunge grinding (Okamoto Machine Tool Works CGM-63)

Grinding conditions:

Wheel speed: 40 m/s

Depth of cut: 2 – 20 µm

Table speed: 12 m/min

Applications

Engineers optimize the abrasive, bond, filler, and porosity, and select the appropriate grade and concentration, to adapt Cera Dia wheels effectively to a wide range of grinding styles and materials based on many grinding cases.

Super-fine abrasive grinding

In recent years, industries have increased their requirements for surface quality and grinding accuracy, creating a need for grinding wheels with super-fine abrasives. Among all super-fine grinding wheels in the world, the Cera Dia wheels ensure efficient, accurate grinding with its excellent sharpness and sustainability. They are also useful in transitioning from loose to fixed abrasive.

Example 1

| Work piece | Lens molds |

|---|---|

| Material | Tungsten carbide |

| Allowance | 0.01 mm or less |

| Grinder | Spherical grinding type (curve generator) |

| Grinding Fluid | Water solution |

| Wheel Speed | 16 m/s |

| Cutting Speed | 2 m/min |

| Wheel | SD 1000 M 75 NF08 (NANOFIX) |

| Type | 1EB |

| Dimensions | 16D×3T×4H |

| Results | Excellent profile holding — Ra 0.01 or less. |

Example 2

| Work piece | Ceramic Sheet |

|---|---|

| Material | Silicon Carbide |

| Grinder | Surface Grinder |

| Grinding Fluid | Water Solution |

| Wheel Speed | 33 m/s |

| Wheel | SD 8000 N 125 NF08 (NANOFIX) |

| Type | 6A2 |

| Dimensions | 250D × 20T × 25.4H × 100W × 3X |

| Results | Mirror finish: excellent |

Vertical spindle parallel-surface honing / lapping

The excellent sharpness and durability of Cera Dia wheels significantly reduce grinding costs by boosting efficiency and extending dressing intervals, even when operators run the wheels at lower speeds in vertical-spindle double-sided grinding.They are especially useful for thin products.  Example 1

Example 1

| Work piece | Throw-away tips |

|---|---|

| Material | Cermet |

| Allowance | 0.4 mm on both sides |

| Grinder | Vertical spindle parallel-surface grinder |

| Grinding Fluid | Water solution |

| Wheel Speed | 1.1 m/s |

| Wheel | SD 600 P 100 CRD1 |

| Type | 1A2T |

| Dimensions | 350D × 48T × 145H × 100W × 3X |

| Results | Surface roughness Ry 2.0. The cycle time does not exceed 360 seconds in 14 cycles after dressing. The excellent sharpness and durability of Cera Dia wheels significantly reduce grinding costs by boosting efficiency and extending dressing intervals, even when operators run the wheels at lower speeds in vertical-spindle double-sided grinding. |

Example 2

| Work piece | Cemented carbide boards |

|---|---|

| Material | Tungsten carbide |

| Allowance | 0.2 mm |

| Grinder | Parallel vertical spindle grinder |

| Grinding fluid | Water solution |

| Wheel Speed | 1.35 m/s |

| Depth of cut | 0.003 mm/min |

| Wheel | SD 140 N 75 CRD3 |

| Type | 1A2T |

| Dimensions | 430D × 45T × 165H × 130W × 3X |

| Results | Surface roughness Ry 6.3 Flatness 30 µm The dressing intervals are 60% longer than those for existing wheels. |

Example 3

| Work piece | Ceramic Sheet |

|---|---|

| Material | Alumina |

| Allowance | 0.4 mm on both sides |

| Grinder | Double-disc surface grinder |

| Grinding Fluid | Water solution |

| Wheel | SD 325 N 100 CRD3 |

| Type | 1A2 |

| Dimensions | 635D × 60T × 232H × 200W × 3X |

| Results | Thickness ±3 μm The wheel achieves dressing intervals of 60 pieces, compared with the current wheel’s 10 to 20. |

Surface grinding

Users apply Cera Dia wheels to ceramics and also use them to grind cemented tungsten carbide and steel simultaneously. They are particularly effective for thin workpieces that require high sharpness.

Example 1

| Work piece | Ceramic Products |

|---|---|

| Material | Silicon Carbide |

| Allowance | 0.1 mm |

| Grinder | Surface grinder |

| Grinding Fluid | Water solution |

| Wheel Speed | 33.3 m/s |

| Depth of cut | 20 µm/pass |

| Wheel | SD 230 P 150 CRD1 |

| Type | 14A1 |

| Dimensions | 250D×19T×50.8Hx10U×3X |

| Results | Surface finish Ry 3.2 — excellent |

Example 2

| Work piece | Metal Parts |

|---|---|

| Material | Tungsten Carbide |

| Hardness | HRc 64–80 |

| Allowance | 0.2 mm |

| Grinder | Surface grinder |

| Grinding Fluid | Dry |

| Wheel Speed | 31 m/s |

| Work Speed | 2–10 m/min |

| Depth of cut | 10 µm/pass |

| Wheel | SD 500 P 100 CRD3 |

| Type | 1A1 |

| Dimensions | 180D×12T×51H×7U×3X |

| Results | Excellent in both sharpness and efficiency |

Example 3

| Material to be Ground | Plate |

|---|---|

| Material | FCD, SCM, etc. |

| Hardness | Hv500 or more |

| Allowance | 20 µm |

| Grinder | Rotary surface grinder |

| Grinding Fluid | Water solution |

| Wheel Speed | 25 m/s |

| Work Speed | 90 m/min |

| Depth of cut | 1 µm/pass |

| Wheel | SD 2000 N 100 CRF3 |

| Type | 14A1 |

| Dimensions | 350D×50T×127H×20U×5X |

| Results | Pretreated with CBN#325. Mirror grinding on ferrous metals eliminates the need for lapping and increases efficiency sixfold. Surface finish Ra 0.03. |

Tool grinding

The Cera Dia wheels are suitable for higher efficient, accurate grinding of cutting tools. Manufacturers use them for grinding PCD, PCBN, ceramics, and other hard materials.

Example 1

| Work piece | Cutting tools |

|---|---|

| Material | Fine particles PCBN |

| Allowance | 0.2–0.5 mm |

| Grinder | Tool grinder |

| Grinding Fluid | Water solution |

| Wheel Speed | 20 m/s |

| Cut | F 0.2 |

| Wheel | SD 1000 P 175 CRD1 |

| Type | 6A2BT |

| Dimensions | 350D×90T×260Hx15W×3X |

| Results | Chipping 10 to 20 µm |

Example 2

| Work piece | Tool tips |

|---|---|

| Material | PCD |

| Allowance | 0.07 mm |

| Grinder | Tool grinder |

| Grinding Fluid | Water solution |

| Wheel | SD 1000 Q 150 CRD1 |

| Type | 6A2BT |

| Dimensions | 350D×90T×260Hx5W×6X |

| Results | Chipping 20 µm — 50% increased service life |

Example 3

| Work piece | Cutter |

|---|---|

| Material | PCD |

| Allowance | 0.05–0.1 mm |

| Grinder | Tool grinder |

| Grinding Fluid | Water solution |

| Allowance | 0.1 mm |

| Wheel | SD 800 U 150 CRF1 |

| Type | 6A2 |

| Dimensions | 125D×18T×16Hx5W×5X |

| Results | Surface finish / sharpness / excellent life |

Example 4

| Material to be Ground | Tools |

|---|---|

| Material | PCD |

| Allowance | 0.02 mm |

| Grinder | Tool grinder |

| Grinding Fluid | Water solution |

| Wheel Speed | 7.9–23.6 m/s |

| Feed rate | 20 oscillations/min |

| Wheel | SD 1500 Q 150 CRD3 |

| Type | 11B2 |

| Dimensions | 150D×50T×50.8Hx15W×5X |

| Results | 30% improved grinding |

Example 5

| Work piece | Tool tips |

|---|---|

| Material | PCD |

| Allowance | 0.3 mm |

| Grinder | Tool grinder |

| Grinding Fluid | Water solution |

| Wheel Speed | 10.5 m/s |

| Depth of cut | 0.15 mm |

| Feed rate | Oscillation width 19 mm — 50 osc./min |

| Wheel | SD 1500 P 200 CRD1 |

| Type | 11A2B |

| Dimensions | 200D×40T×60H×20W×5X |

| Results | Chipping 10 µm excellent |

Example 6

| Work piece | Single-flute DC gun reamer |

|---|---|

| Material | PCD & tungsten carbide |

| Allowance | 0.05 to 0.1 mm |

| Grinder | NC tool grinder |

| Grinding Fluid | Water solution |

| Wheel Speed | 16.7 m/s |

| Depth of cut | 0.003 mm (total 0.15 mm) |

| Feed rate | 20 oscillations/min |

| Wheel | SD 600 Q 150 CRD1 |

| Type | 11V9BT |

| Dimensions | 100D×17T×38.1H×5U×3X |

| Results | Chipping 20–30 µm, depth of cut improved 60% |

Cylindrical grinding

Cera Dia wheels grind cemented tungsten carbide and steel simultaneously and also handle various ceramics effectively. Their sharpness makes them especially useful for thin products that require precise grinding.

Example1

| Work piece | Lathe center |

|---|---|

| Material | Tungsten carbide + SK5 |

| Allowance | 2.0 mm |

| Grinder | Cylindrical grinder |

| Wheel Speed | 33.3 m/s |

| Wheel | SD 400 M 100 CRD1 |

| Type | 14A1R |

| Dimensions | 300D × 30T × 127H × 8U × 3X |

| Results | Slightly uneven surface compared with resin wheel, improved performance |

Internal grinding

The wheel achieves excellent finishing accuracy and grinding efficiency through its high rigidity and sharpness.

Example1

| Work piece | Ceramics |

|---|---|

| Material | Zirconia |

| Allowance | φ0.03 mm |

| Grinder | Internal grinder |

| Wheel Speed | 30 m/s |

| Wheel | SD 800 N 200 CRD1 |

| Type | 1A1 |

| Dimensions | 8D × 6T × 1.5X |

| Results | Surface finish Ra 0.2 — excellent |