Nitolex Corporation

Nitolex Tufflex Wheels

Manufacturer: Nitolex Corporation

Model: Tufflex

Features

Heat-resistant resin bond wheel

Tufflex wheels are high-performance wheels made of polyimide resin specially modified by us for super abrasive wheels to ensure excellent sharpness and durability at the same time.

Tufflex wheel ultra-heat-resistant resin

Tufflex wheel ultra-heat-resistant resin

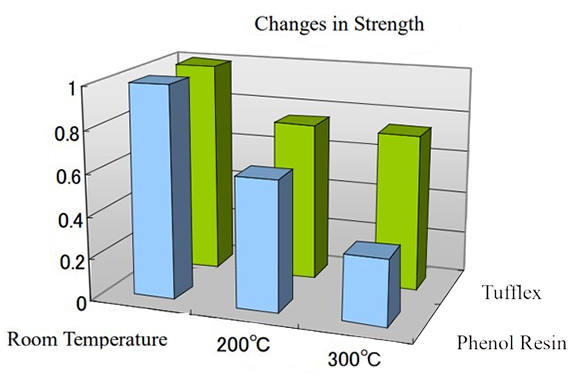

1. Strength does not decrease when hot. In bending strength tests while heated, phenol resin fell to 30% of its room temperature strength when heated to 300°C, while Tufflex maintained 70% strength.

2. Tufflex has a higher heat deformation temperature than phenol resin.

3. Tufflex demonstrates high gripping strength of grain while grinding.

Features of Tufflex Bond

High performance grinding

Efficient grinding is realized by the excellent sharpness ensured by strong gripping strength of grain and the use of a heat-resistant bond that has a hither heat deformation point and does not degrade in strength when hot.

Excellent Profile Holding

Demonstrates particular efficiency in grinding requiring profile holding due to excelling durability.

Excellent wheel life

Greatly improved wheel life due to excellent durability.

Application CBN Wheels

Bonds

| Grinding conditions | Bonds | |

|---|---|---|

| Wet | Tool steel medium/heavy grinding | PT8 series |

| Die steel medium/heavy grinding | IPT series | |

| Tool/die steel heavy grinding | FPT · TPT series |

Sintered Alloy

Nippei vertical spindle surface grinder – wet (water solution)

Wheel speed: 16 m/s Work speed: 35 m/min Depth of cut: 0.20 mm

Wheel: CBN 80 R 125 TPT87 6A2 40D x 35T x 5W x 3X

| Tufflex | Conv. Resin | |

|---|---|---|

| Sharpness | Excellent | Normal |

| Surface roughness | 0.3 µm Ra | 0.35 µm Ra |

| Dressing interval | Not required | Not required |

| Wheel life | 210% of conv. | — |

Die steel

Okamoto surface grinder – wet (water solution) creep grinding

Wheel speed: 30 m/s Work speed: 120 mm/min Depth of cut: 1.5 mm

Wheel: CBN 140 M 125 PT82 1L1 200D x 10T x 31.75H x 3X

| Tufflex | Conv. Resin | |

|---|---|---|

| Sharpness | Feed: 120 mm/min | 60 mm/min |

| Dressing interval | 5 pieces | 2 pieces |

| Wheel life | 200% of conv. | — |

Applications Diamond wheel

Bonds

| Grinding conditions | Bonds | |

|---|---|---|

| Wet | Carbide/ceramics medium/heavy grinding | PT8 series |

| Cermet grinding | VPT・RPT series | |

| Carbide/steel simultaneous | JPT series | |

| Dry | Carbide medium/heavy grinding | PTN series |

Example Applications

Carbide

Makino Seiki wet (oil-based) drilling groove grinding

Work: φ6 mm (Grinding length 80 mm) Removal stock: 2.5 mm

Wheel speed: 25 m/s Work speed:70mm/min Depth of cut: 2.5 mm

Wheel: SDC 270 P 125 PT81 14FF1 150D x 10T x 31.75H x 6U x 5X

| Tufflex | Conv. Resin | |

|---|---|---|

| Feed | 70 mm/min | 30 mm/min |

| Dressing interval | 50 pieces | 40 pieces |

| Wheel life | 125% of conv. | — |

| Grinding efficiency | 230% of conv. | — |

Alumina

Washino surface grinder – wet (water solution)

Work: 30 mm x 10 mm x 25 mm Removal stock 0.1 mm

Wheel speed: 25 m/s Work speed: 10 m/min Depth of cut: 10 µm

Wheel: SDC 230 N 100 PT81 14A1R 200D x 25T x 31.75H x 3U x3X

| Tufflex | Conv. Resin | |

|---|---|---|

| Depth of cut | 10 µm | 5 µm |

| Dressing interval | 15 pieces | 8 pieces |

| Wheel life | 200% of conv. | — |