Nitolex Corporation

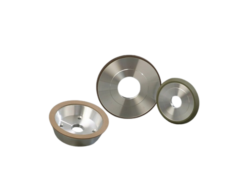

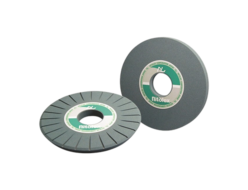

Nitolex SP Wheels

Manufacturer: Nitolex Corporation

Model: SP

Features

The SP wheels are CBN bonded wheels developed for compression springs surface grinding of disc type grinding (double disc surface grinding)

The SP wheels prove excellent grinding performance with the special bond and solve problems in the springs business world.

In addition, they open a way to full automation and lower personal expence.

Characteristics

1. No dressing

Dressing is not necessary with its sharp edge that doesn’t load.

2. Reduced the inspection charge of spring load and free length.

As compared with conventional wheels, the SP wheels are only worn to about one hundredth, The spring load and free length have been constanted. Therefor it greatly saves the inspection time.

3. Vastly reduced wheel turnorver rate.

Because of longer wheel life, the wheel turnover rate can be reduced to a tenth or less.

4. Adapted various materials

SP wheels grind excellent sharpness both steel wire and stainless steel wire. Wheels no longer need to be replaced depending on the materials..

5. Clean operation

Almost few fine particule of grinding wheels, the work environment is comfortably improved.

Coiling surface grindineg for compression springs

| SP wheels | Conventional | |

|---|---|---|

| Wheel | CBNC 80 R 225D×38T×26H×84.5W×3X | A 46 P V 255D×40T×86H |

| Material | Coil spring (sus, swp) wire diameter 0.5–1.6 mm | |

| Grinder | Syowazoki VP2-20-S (Dry) | |

| Dressing | Non-necessity | 2 to 3 times/day |

| Wheel life | 10 months | 20 days |

| Results | Reduced the inspection charge of spring load and zero defects due to deformation. | |

Snap ring surface grinding

| SP wheels | Conventional | |

|---|---|---|

| Wheel | CBNC 100 P 455D×48T×87.5W×3X | SA 80 M B 455D×65T×280H |

| Material | Snap ring (S60C HV440–450) φ32.5 | |

| Grinder | Nippei V-18 | |

| Dressing | 0.5 times/week | 3 times/day |

| Wheel life | 6 months | 0.5 months |

| Results | Reduced much personal expenses of inspection free length and wheels turnover rate. | |

* The CBN abrasive, manufactured with the ultra-high temperature/pressure technology, is the hardest material in the world after diamond. It is twice as hard as conventional grain WA and GC and help maintain sharp edges to realize efficient grinding.