Suntest

Suntest GY Series GYPS Probe

Manufacturer: Suntest Co.,Ltd

Model: GYPS

Magnetostrictive Displaiacement Transducer

Model GY Series are “Displacement Transducers” employing magnetostrictive phenomena, especially the Wiedemann effect. An ultra-sonic wave is generated by a moving magnet operating near a magnetostrictive wave guide on which the sonic wave propagates up to the head of the transducer.

Model GY Series are “Displacement Transducers” employing magnetostrictive phenomena, especially the Wiedemann effect. An ultra-sonic wave is generated by a moving magnet operating near a magnetostrictive wave guide on which the sonic wave propagates up to the head of the transducer.

The propagation time is precisely measured by state of the art technology and then the absolute displacement transducer is operational.

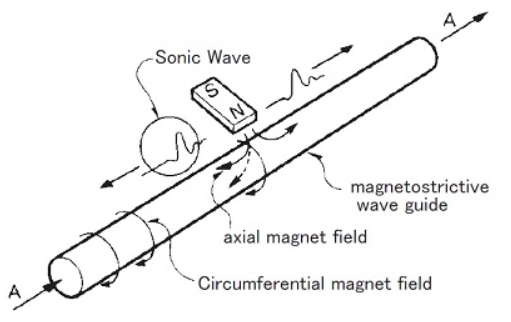

[ Principle ]

The figure shows the fundamental principle of operation.

When a current pulse like A is given to the wave guide, it generates a circumferential magnetic field on the wave guide, then placement of the movable magnet (polarized axially) as shown, only the axial magnetic field of the magnet affecting the wave guide produces a resultant field as indicated by the dotted line.

The vector combination of these two fields produces torsional strain, a phenomenon known as the Wiedemann Effect.

It is a form of vibration and propagates along the wave guide in the form of a transverse ultra-sonic wave.

The GY series displacement transducers detect the propagation time of the ultra-sonic wave.

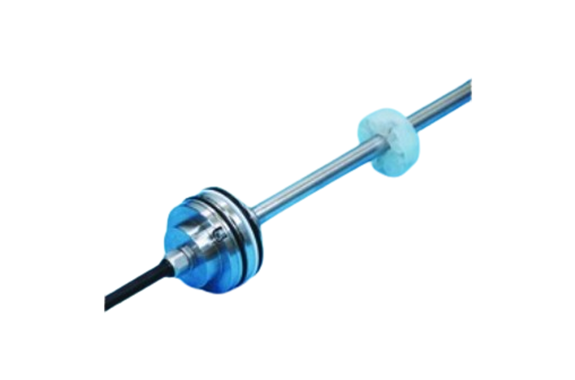

GYPS Probe (Analogue / PWM / CANopen/SAEJ1939)

for built-in small hydraulic cylinder

GYPS probe is the sensor for built-in hydraulic cylinder which has analogue output.

GYPS probe is the sensor for built-in hydraulic cylinder which has analogue output.

The sensor head is compact and the head dead zone is also short, so its total length becomes space saving.

With the dedicated software (GPM), zero and gain adjustment is possible at the user.

Max. effective stroke is 2400mm.

Specifications

| Non-linearity | ≦±0.1mm (30-250mm) ≦±0.04%FS (251-2000mm) ≦±0.8mm (2001-2400mm) |

|---|---|

| Resolution | ≦0.06mm *CANopen:≦0.1mm |

| Reapeatablity | ≦±0.06mm *CANopen:≦±0.1mm |

| Temp. drift | ≦±0.006%FS/°C |

| Voltage output | 0.25〜4.75V、0.5〜4.5V 0〜10V (load: Min.2kΩ) |

| Current output | 4〜20mA (load: Max.250Ω) |

| PWM output | 1kHz 5V 95-5% (load : Min.5kΩ) |

| CANopen | CiA-301 version 4.2 CiA-305 version 3.0.0 DS-406 version 4.2 |

| Power supply | +8〜36VDC (≦0.8W) |

| Sampling freq. | Std. 1kHz (Total rod length : 1300mm) |

| Max. Pressure | 45MPa (continuous operating pressure) |

| Operating Temp. | -20°C〜+85°C |

| Storage temp. | -20°C〜+85°C |

| Vibration | 20G (5〜2000Hz) |

| Shock | 100G (2msec) |

| IP grade | IP67 |

(*): Changed the values for CANopen output. (20230208)

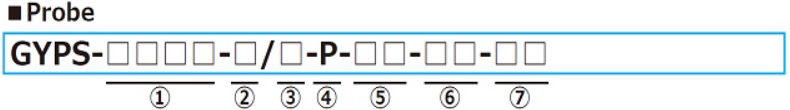

Model No.

① Effective stroke

30mm〜2400mm

② Head dead zone

15 :15mm(Std.)

□ :□mm (option)(specified by customers)

③ Tip dead zone

70 :70mm(Std.)

□ :□mm (option)(specified by customers)

④ Mount / Rod diameter

P :O-ring, rod Φ10 (Std.)

⑤ Associated magnet

< Magnet >

M3 :No.3

・Please consult if you select a magnet of the other than above.

・This Model code means only specifying associated magnet.

・Ordering magnet individually.

⑥ Cable connection

SG□F :pigtail / cable end : free

SG□A :pigtail / cable end : with connector for relay

(□ :cable length(m)、Max.10m)(*)

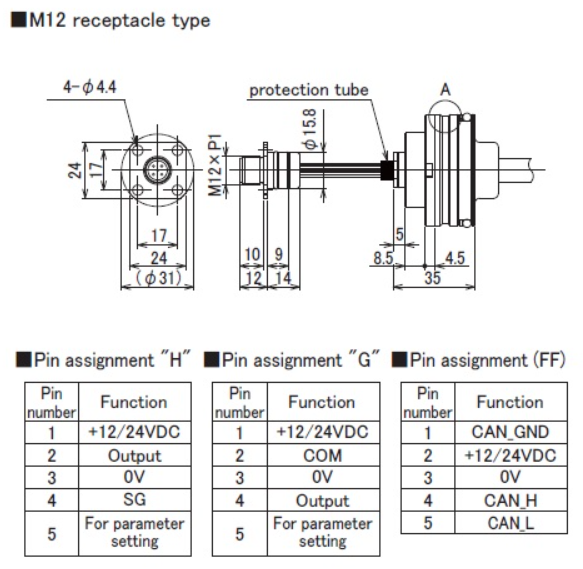

KV□△ :M12 receptacle type

□ :wire length (by 0.01m), Max.0.1m

△ :pin assignment( H: pin assignment “H”, G: pin assignment “G”,

FF: pin assignment “FF”)

(*) In case of using extension cable

Voltage output : sensor cable (m) + extension cable (m) ≦ 10m

Current output : sensor cable (m) + extension cable (m) ≦ 100m

PWM output : sensor cable (m) + extension cable (m) ≦ 10m

⑦ Position output

A1 :0.25〜4.75V (When magnet moves toward tip, output increase.)

A2 :4.75〜0.25V (When magnet moves toward tip, output decrease.)

A3 :0.5〜4.5V (When magnet moves toward tip, output increase.)

A4 :4.5〜0.5V (When magnet moves toward tip, output decrease.)

AD :0〜10V (When magnet moves toward tip, output increase.)

AR :10〜0V (When magnet moves toward tip, output decrease.)

BD :4〜20mA (When magnet moves toward tip, output increase.)

BR :20〜4mA (When magnet moves toward tip, output decrease.)

PWM1 :1kHz 5V (5〜95%)

PWM2 :1kHz 5V (95〜5%)

CO : CANopen

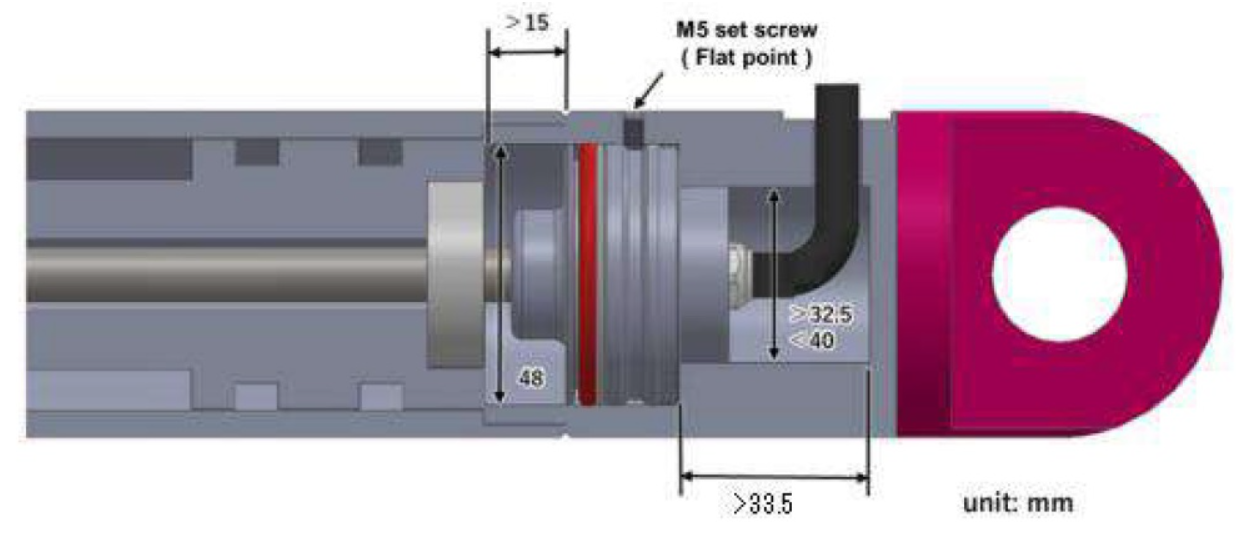

Dimensions

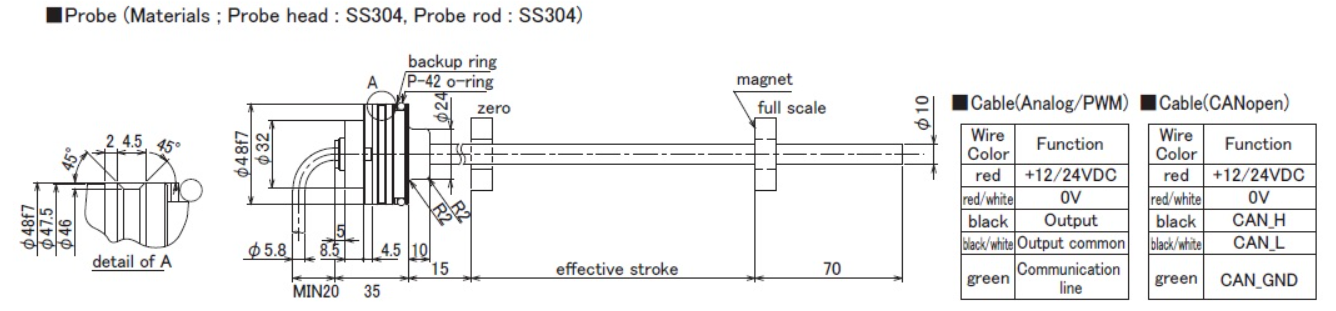

Probe

M12 receptacle

Installation example