Simotec

Simotec Magnet Holder (Permanent Magnet Holder)

Manufacturer: Shimonishi Giken Kogyo Co., Ltd

Product name: Magnet Holder (Permanent Magnet Holder)

Features

- ・Black oxide finish (※) improves rust prevention

- *Black oxide treatment: A method of forming black rust on the surface through a chemical reaction, preventing further rusting.

- – Screw holes on the opposite side of the suction surface make installation easy

- ・By covering the magnet with a metal holder, the attraction force and mechanical strength are improved compared to the magnet alone.

- – To enhance the attraction force, the magnetic circuit concentrates the magnetic force, and even though it is small, it exerts a strong and uniform attraction force.

- ・We handle three types of magnets.

- *Features by type

- [Neodymium magnet type] Strong adhesion

- [Samarium-cobalt magnet type] High heat resistance and strong adsorption

- [Alnico magnet type] Ultra heat-resistant adsorption

Magnet holder types

■Neodymium magnet type

This is a magnet holder with the strongest adhesive force. However, its adhesive force weakens when heated, so it is not suitable for use in high temperatures. Its corrosion resistance is also inferior to other types, so many products are plated.

Because of its strong magnetic force, it is often used to secure heavy objects and small precision instruments.

■Samarium-cobalt magnet type

Although their attractive force is weaker than that of neodymium magnets, they have excellent corrosion resistance and heat resistance, and can maintain their performance even in high-temperature and chemically harsh environments. For this reason, they are used in aerospace and research facilities and other places where high reliability is required.

■Alnico magnet type

Although their adhesive power is weaker than that of neodymium magnets and samarium-cobalt magnets, their magnetic properties are less temperature-dependent, and they retain their high magnetic force even in high-temperature environments. They are also characterized by their high physical strength compared to other magnets. They are widely used in sensors, measuring equipment, educational applications, etc.

Purpose of use

- – Fixing workpieces under high temperatures, such as in welding and painting lines

- ・Workpiece clamping and holding for wire discharge machines

- – Fixing drawings, rulers, etc., and attaching them to jigs and tools

- ・Attachment to molds, etc.

specification

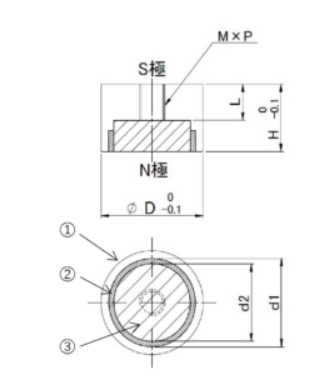

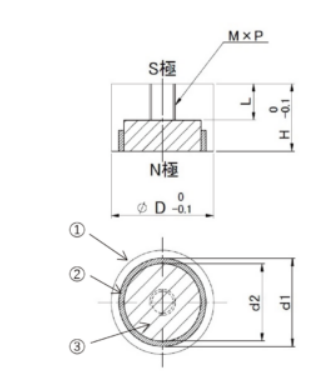

[Neodymium magnet type]

| Part Number | Diameter x Height (mm) | Thread depth (mm) | M×P | Adsorption force (N) | Heat-resistant temperature (℃) | Material |

|---|---|---|---|---|---|---|

| CE0189-A01A | 6×8 | 5.8 | 3×0.5 | 4.5 | 80 |  ①SS400 (black dye) ②Brass (C3604 cadmium-free) ③Neodymium magnet |

| CE0190-A01A | 8×8 | 5.8 | 3×0.5 | 6 | ||

| CE0191-A01A | 10×8 | 4.9 | 4×0.7 | 20 | ||

| CE0192-A01A | 13×10 | 5.8 | 4×0.7 | 50 | ||

| CE0193-A01A | 16×10 | 5.8 | 5×0.8 | 80 | ||

| CE0194-A01A | 20×13 | 6.8 | 5×0.8 | 135 |

[Samarium-cobalt magnet type]

| Part Number | Diameter x Height (mm) | Thread depth (mm) | M×P | Adsorption force (N) | Heat-resistant temperature (℃) | Material |

|---|---|---|---|---|---|---|

| CE0183-A01A | 6×8 | 5.8 | 3×0.5 | 2.9 | 230 |  ①SS400 (black dye) ②Brass (C3604 cadmium-free) ③Samarium-cobalt magnet |

| CE0184-A01A | 8×8 | 5.8 | 3×0.5 | 4.9 | ||

| CE0185-A01A | 10×8 | 4.9 | 4×0.7 | 20.0 | ||

| CE0186-A01A | 13×10 | 5.8 | 4×0.7 | 39.0 | ||

| CE0187-A01A | 16×10 | 5.8 | 5×0.8 | 59.0 | ||

| CE0188-A01A | 20×13 | 6.8 | 5×0.8 | 78.0 |

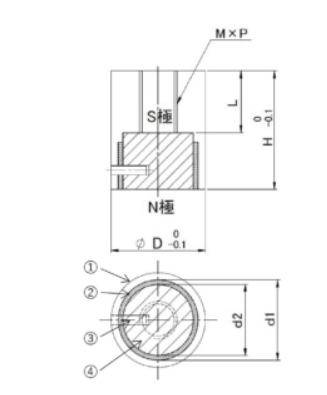

[Alnico magnet type]

| Part Number | Diameter x Height (mm) | Thread depth (mm) | M×P | Adsorption force (N) | Heat-resistant temperature (℃) | Material |

|---|---|---|---|---|---|---|

| CE0195-A01A | 10×15 | (8.1) | 5×0.8 | 5 | 300 |  ①SS400 (black dye) ②Brass (C3604 cadmium-free) ③Brass (C2700) ④Alnico magnet |

| CE0196-A01A | 13×15 | (8.1) | 5×0.8 | 6 | ||

| CE0197-A01A | 16×20 | (10.1) | 6×1.0 | 18 | ||

| CE0198-A01A | 20×25 | (13.1) | 8×1.25 | 29 |