Simotec

Simotec Skived Heat Sink

Manufacturer: Shimonishi Giken Kogyo Co., Ltd

Product name: Skived Heat Sink

overview

Fins are create by skiving, a processing method that thinly peels off the surface of the material. This method is suitable for creating thin, narrow-pitch fins. Therefore, when combined with a forced-air cooling fan, it is possible to create a high-performance heat sink.

Materials with high thermal conductivity, such as aluminum and copper, can be used.

Features

- – The base and fins are integrate for efficient heat transfer.

- ・Compared to general extrusion molding, it is possible to create thinner, narrower pitched, and taller fins.

- ・No mold is require making it suitable for small-lot production

Purpose of use

- ・Cooling of semiconductor elements and electronic circuits

- ・Power supplies, power semiconductor cooling, etc.

General processing conditions

Fin thickness: 0.2mm or more

Spacing: 0.2mm or more

Fin height: 90mm or less

Varies depending on shape.

Specification example

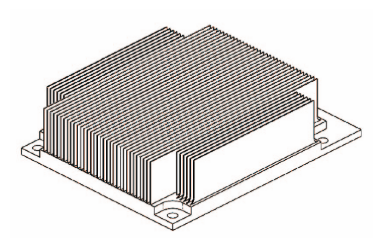

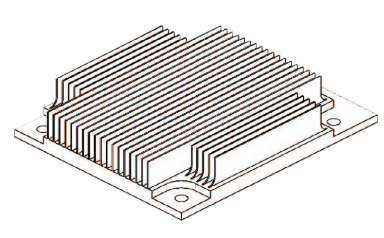

| Supported heat output | Structural diagram | External dimensions (reference value) W x D x H | Thermal resistance (reference value) |

|---|---|---|---|

| ~200W |  | 91×113×28 mm | 0.19℃/W (wind speed approximately 5m/s) |

| ~40W |  | 57×67×12 mm | 0.90 ℃/W (wind speed approximately 3.5m/s) |