Kitagawa Corporation.

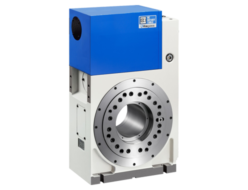

Kitagawa Short Taper Of Lathe Spindle Chuck Parts

Manufacturer: Kitagawa Corporation.

Model: Short taper of lathe spindle

Feature:

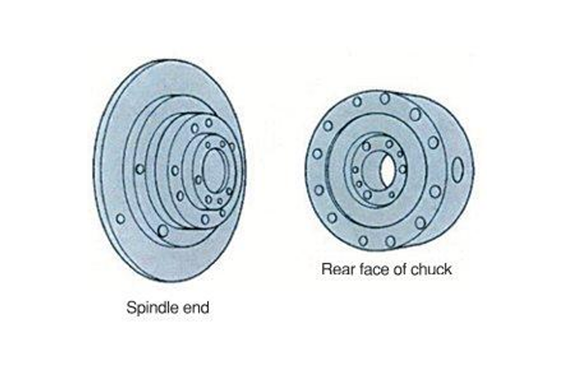

About lathe spindle end

“ISO, ASA, DIN, and other organizations (except JIS) stipulate the standards covering the lathe spindle end.

Japan major lathe manufacturers manufacture the great majority of lathe spindle end parts at standards of JIS-A1. A2 (IS0-A1. A2). However, manufacturers produce a part of lathe spindle end parts based on ASA-A1 and A2 standards.

Although the spindle end dimensions according to each standard are the same, the dimensional tolerance of a face plate (chuck or back plate) varies by a few microns.

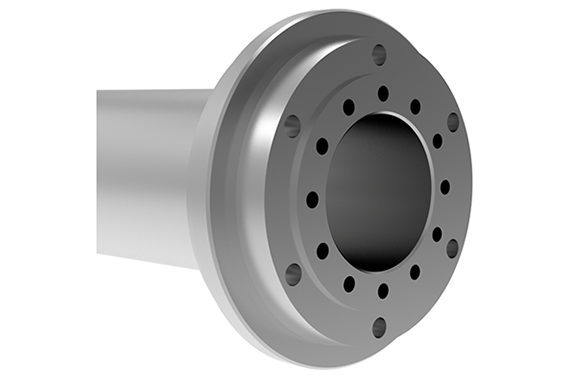

Mounting the short taper (direct type) chuck for spindle end

The taper diameter of the short taper chuck for the spindle end is small slightly and the chuck has the some amount of interference (tolerance). Setting the chuck creates a small gap between the mutual mounting end faces, and tightening the mounting bolts brings the chuck into close contact. (The face having mounting bolt holes is the mounting face.) Tighten the chuck evenly by screwing bolts diagonally.

When interference (tolerance) of the chuck is large or small, any gap may occur in diameter direction. In the former case, mounting the chuck may cause it to deform. In the latter case, a gripping accuracy becomes low for increasing a mounting error. Similarly, tightening the scroll chuck excessively when mounting it to the small end face of the spindle end taper will also cause it to deform.Thus, the handle operation or chuck motion becomes heavy extremely. Moreover, take care since the more interference,

the more failure becomes large.

X-See a lathe matching list of the short taper chuck.

If you need taper correction, please consult our company since we charge a separate correction fee.

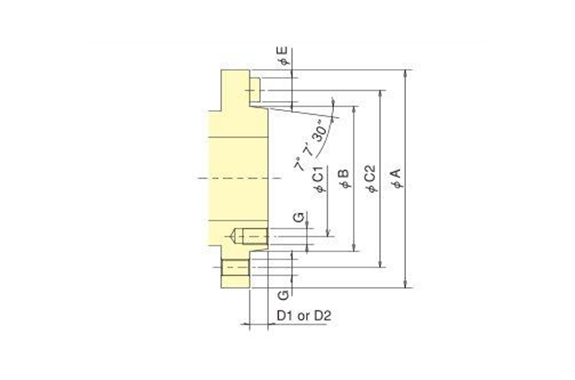

JIS B 6109-1: 2005

JIS B 6109-1: 2005

Machine Tool – Lathe Spindle End and Chuck mounting dimensions

Part 1: Extract ‘Mounting Short Taper”

| Code | Spindle Nose Number | ||||

| 5 | 6 8 11 | 15 | |||

| A | 133 | 165 | 210 | 280 | 380 |

| B | 82.563 | 106.375 | 139.719 | 196.869 | 285.775 |

| Cl | 61.9 | 82.6 | 1 1 1.1 | 165.1 | 247.6 |

| C2 | 104.8 | 133.4 | 171.4 | 235 | 330.2 |

| DI | 14.288 | 1 5.875 | 17.462 | 19.05 | 20.638 |

| D2 | 13 | 14 | 16 | 18 | 19 |

| E | 15.9 | 19.05 | 23.8 | 28.6 | 34.9 |

| G | MIO | M12 | M16 | M20 | M24 |

Note 1: C1 is Shown on A1 Spindle Nose

Note 2: D1 is shown on A1 Spindle Nose and 02 is done on A2 one

For order of separate jaw scroll chucks JN-RA for short taper

When placing an order, establish contact with your agent or our company to advise a manufacturer name

and type of a lathe used in a customer shop.

Since the dimensional tolerance of spindle end face may vary by manufacturers, it is necessary to correct the taper of the chuck rear body. (Please understand that there is a fluctuation of a delivery date and a price.)

Moreover. JN-RA types are standard and chuck mounting M bolts are packed together with the chuck.Since each chuck mounting bolt is manufactured at inch (UNIHI bolt or wit screw) by manufacturers, confer with our company.