Japan, UHT CORPORATION

UHT CORPORATION FP Series Flexible Substrate Punching Machine

Made in Japan

Manufacturer: UHT CORPORATION

Model: FP series (FP-1213, FP-1018)

Features

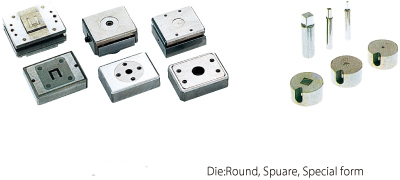

- Combining different types of 12-axis punches without a special die allows various types of machining.

※FP-1213:12-axis, FP-1018:10-axis - Easier data inputting by teaching.

- Installing the testing system.

Characteristics

- Materialized high-speed punching 600 holes/min.

- High-precision machining by image processing system.

- The testing installation can control quality.(OP.)

- A specisl form punch allows complicated pattern machining.

- The conversational touch panel using the new type controller facilitates operation.

- Built-in device removing static electricity

Standard Specifications

| Model name | FP-1213 | FP-1018 | |

|---|---|---|---|

| Work | Material | Flexible substrate (FPC) | |

| Thickness | Max. 1.0mm | ||

| Size | Max. W510×D330mm (Max. 360mmOP.) | Max. W610×D460mm | |

| Machining area | Max. W500×D320mm (Max. 350mmOP.) | Max. W600×D450mm | |

| Basic work holder | Max. W560×D380mm (Max. 405mmOP.) | Max. W660×D510mm | |

| Way of installing | Taped to V/F finger (Eguipped with 0 corre ction me chanism) + Work holder (Taped outside and inserted into the machine) | ||

| Feeding position | Hand-feeding from the left side of the machine | ||

| The Number of The Punch Units PU-25 loading shaft | 12 axis | 10 axis | |

| Decided by you (See the applicable sheet) | |||

| Capability | Punching precision | ±10μm (precision at the machining point within 25mm pitch in the standard punching range using UHT test film) | |

| Punching speed | Max. 600 holes/min (NC machining on PU-25 at 1mm pitch in Y direction) | ||

| Moving speed | Max. 30m/min. (simultaneous 2-axis control) | ||

| Control function | Control unit | UHT make controller exclusively for mechanism control(MJUC) | |

| Operation | Graphical operation by 6.5 inch touch panel | ||

| Testing item (OP) | Positioning a hole to a mark | ||

| Data | Machining data preparation | Dedicated interactive software on PC Teaching input method | |

| Data storage capacity | 1 file (30,000 positions) | ||

| Network | Transmission of machining data from PC to the machine through LAN | ||

| Static eliminating unit | Air/ionizers installed in the upper and lower parts of the left side of the main body | ||

| Dust disposal | 3-line sucking type | ||

| Safety device | Hood, Door sensor | ||

| Power source | 3φ AC200V ±10% 2kVA | ||

| Air pressure source | 0.4~0.7MPa | ||

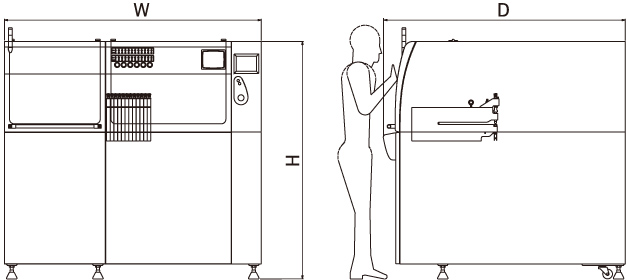

| Machine size | W1770×D1550×H1600mm | W1850×1725×1600mm | |

| Machine weight | Approx. 1200kg | Approx. 1300kg | |

| Working condition | Temperature | 10~35℃ (22±2℃ recommended) | |

| Humidity | 40~60%(Non-bedewing) | ||

| Main options | 1. Automalized module 2.Specifications of main body side applicable to servo unit 3.Powerbox 4.P.C 5. CAD converting software 6. Punch break detecting software 7. Punch unit/die 8.Punch setter 9.Lift car 10,Work holder 11.Front safety sensor | ||

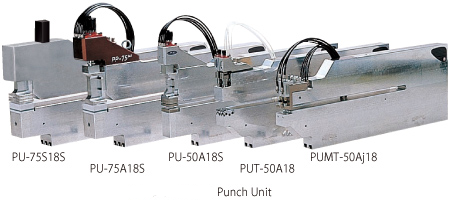

Compatible Unit

| Punching Area | Compatible Unit | ||||||

|---|---|---|---|---|---|---|---|

| FP-1213 | 13 inch | PU-25A13 PU-25A13S PU-25A13φ6 | PU-50A13 PU-50A13S PU-50BA13 PU-50BA13S PU-50S13S PUT-50A13 PUT-50Lj13S PUT-50L13S | PU-75A13 PU-75A13S PU-75S13S PU-75A13da | PU-100A13S PU-100S13S | PU-125A13S | PU-150A13S |

| FP-1018 | 18 inch | PU-50A18 PU-50A18S PU-50BA18 PU-50BA18S PU-50S18S PUT-50A18 PUT-50A18S PUMT-50Aj18 PUT-50Lj18S PUT-50L18S | PU-75A18 PU-75A18S PU-75S18S PU-75A18da | PU-100A18S PU-100S18S | |||

Outline Drawing