Made in Japan

Manufacturer : Nippon Chemical Screw

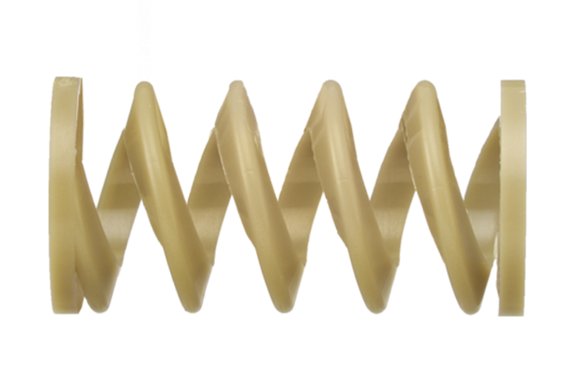

Model :PEEK/PB(Inner diameter-Outer diameter-free length)L

Polyetheretherketone plastic spring.

| Continuous use temperature | 260°C/500°F |

| Combustion quality | UL94V-0 |

| Inner diameter | 1 | 2.2 | 4 | 4 | 4 | 4 | 4 | 4.5 | 5 | 5 |

| Outer diameter | 2 | 3 | 6 | 8 | 8 | 8 | 8 | 10 | 9 | 9 |

| free length | 8 | 20 | 25 | 20 | 30 | 40 | 50 | 18 | 20 | 30 |

| Close contact length | 5 | 10.7 | 12.5 | 12.5 | 18 | 24 | 30 | 11 | 12 | 18 |

| spring constant | 0.54 | 0.06 | 0.38 | 1.57 | 0.833 | 0.624 | 0.45 | 3.48 | 0.903 | 0.679 |

| ─ | ─ | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Inner diameter | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 7.5 | 8 | 8 | 8 | 8 | 8 |

| Outer diameter | 9 | 9 | 10 | 10 | 10 | 10 | 12 | 10 | 12 | 12 | 12 | 12 | 14.5 |

| free length | 40 | 50 | 20 | 30 | 40 | 50 | 25 | 17.2 | 20 | 30 | 40 | 50 | 23 |

| Close contact length | 24 | 30 | 11 | 18 | 24 | 31 | 14.5 | 6.5 | 12 | 18 | 24 | 30 | 11 |

| spring constant | 0.535 | 0.428 | 0.62 | 0.992 | 0.761 | 0.78 | 3.96 | 0.053 | 0.49 | 0.365 | 0.333 | 1.03 | 0.52 |

| ─ | ─ | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

- Spring constant (N/mm), adhesion length, and spring constant are reference values.

- Durability and chemical resistance vary depending on usage conditions, so be sure to test under usage conditions.

- Constant of sprong (N/mm).

- Closed length and spring rate are reference values.

- Since durability and chemical resistance change based on usage conditions, please test under actual usage conditions beforehand.

Sales unit Quantity

Torsional rupture torque

Tensile rupture force

- We use raw materials that are RoHS2 compliant.

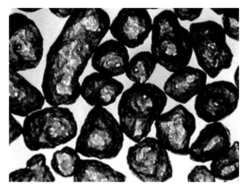

- Black spots (sludge) may appear on the exterior.

- The remaining gate at the screw tip is less than 5% of the length (L).

- Please use in combination with a nut made of the same material as the thread pitch may shift during molding.

- If a nut is not used, the fit with the female thread should be 20 mm or less.

Features

- The values in the table are reference values and are not guaranteed values.

- Please use a torque driver and torque wrench for tightening. The recommended tightening torque is 50% of the breaking torque value under use.

- Heat resistance and chemical resistance vary depending on usage conditions, so be sure to test under usage conditions beforehand.

- There may be slight discoloration depending on the lot and various conditions.

- Inventory sizes, shapes, and manufacturers of materials used are subject to change without notice.