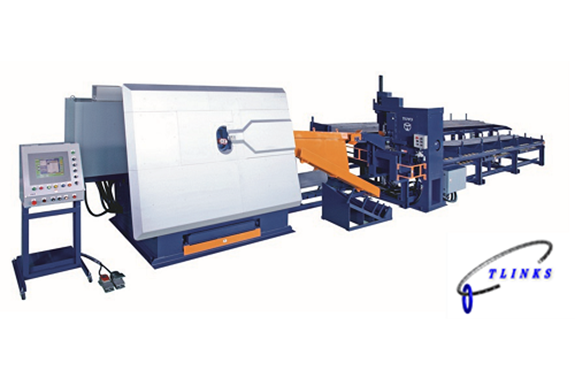

Japan, Toyo Kensetsu Kohki

TOYO KENSETSU KOHKI TBC-16RBⅡV AUTO CUTTING & BENDING

Products Made in Japan

Manufacturer: TOYO KENSETSU KOHKI

Model: TBC-16RBⅡV

Features

- AUTO CUTTING & BENDING

- Bar (Small)

- Reduce manpower

- IT

- Complicated processing

- Rebar fabrication

- Precast concrete

| Model | TBC-16RBⅡV |

|---|---|

| Capacity | SD345: D10-1 ~ D16-1 SD390: D10-1 ~ D13-1 |

| Required breaker capacity | 75A |

| Bending unit revolution | MAX187.0rpm |

Machine & Processing

Specifications

| Specifications | TBC-16RBIV (12m) |

| Required breaker capacity | 75A |

| Processable material length | 4,000~12,000mm |

| Max. q’ty loadable on the material plat form | D10:400pcs., D13:220pcs., D16:140pcs. |

| Bending angle | Upward 5°~135°Downward 5°~180° |

| Bending unit revolution | MAX 187.0 rpm |

| Feeding speed | MAX 155.0 m/min |

| Total motor capacity | 20.9kW (including air compressor) |

| Dimensions (L×W×H) | 16,400×2,105×2,200mm |

| Total weight | 6,500kg |

Similtaneous Max. Bending Quantity (pcs)

| Rebar diameter | D10 | D13 | D16 |

| Fulcrum roller dia. | Φ35 | Φ35Φ39 | Φ48 |

| SD345 | 1 | 1 | 1 |

| SD390 | 1 | 1 | _ |

Details

・Anyone is welcome to operate TBC-16RB IIV due to its user-friendly design.

・TBC-16RB IIV is capable of processing complicated shapes and shapes taking time to set in an automatic way, which raises productivity of other machines, contributing to efficiency increase at fabrication plant as a whole.

・Material is supplied to TBC-16RB IIV automatically from material platform, and then cutting and bending is carried out in an automatic way.

・Material to process can be selected from 2 kinds of rebar and it can be supplied automatically.

・TBC-16RB IIV is most suitable for processing complicated or small dimensions shapes and high-mix low-volume production.

・Remnant materials are cut to the length for reuse.

・PC is equipped, which enables you to send processing data from office to TBC-16RB IIV. (Under network environment)

・30000 kinds of processing data can be registered.