Japan

Round Joint Key for Prestressed Concrete Precast Blocks

Product: Made in Japan

Manufacturer: Kozo Kanagu Kaihatsu

Model: Round Joint Key

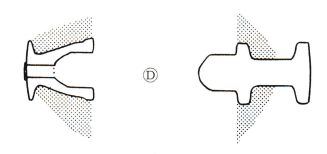

Disassembled condition after manufacturing

Stored condition

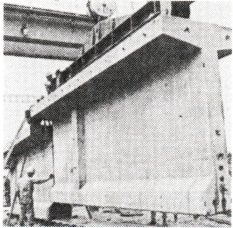

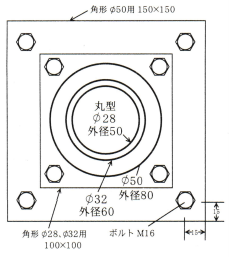

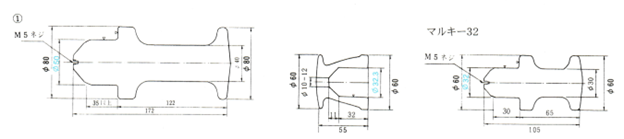

The method of the prestressed concrete precast block, which has superiority in quality control in concrete bridge manufacturing, takes advantage of the reduction of the construction period and also promotes saving the project cost for temporary facility, formwork usage, and land rental for site work. This product is utilized with conditions such as short-term execution, improper place for cast in-situ work, and advisable at one-place work in the method. There are three sizing as diameter 28mm, 32mm, and 50mm.

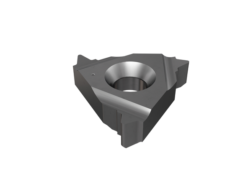

The product was developed by improvement of conventional square-shape type and has the marit to adopt are following.

- Since the size became smaller than the square shape type, the degree of flexibility for reinforcement arrangement in a section becomes higher.

- This product can make a more rigid connection rather than square-shape type usage because of no deformation by hot processing due to the finishing work by machining applied on the product after hot processing.

- There is no eccentric force in the connection part at disassembly work since only one bolt connects the components in the setting product.

- The exposed area, in contact with the concrete body, became lesser.

- The bolting connection part can be removed easily.

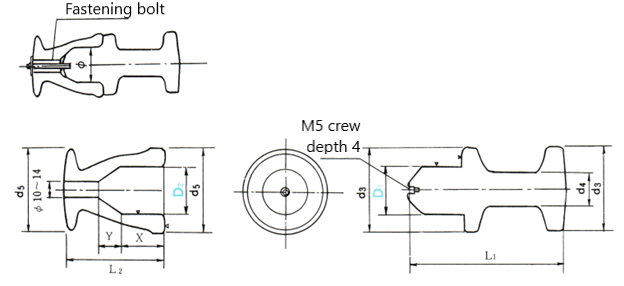

Specification

Material property; FCD450 or more than the equivalent | |||||||||||

| Model | L1 | D1 | D3 | D4 | L2 | D2 | D5 | X | Y | Capacity of key [ton] | Article |

| ɸ28 | 93 | ɸ28 | ɸ50 | ɸ20 | 59 | ɸ28.3 | ɸ50 | 27 | 13 | 6 | |

| ɸ32 | 105 | 32 | 60 | 30 | 55 | 32.3 | 60 | 32 | 11 | 8 | |

| ɸ50 | 172 | 50 | 80 | 40 | 79 | 50.3 | 80 | 37 | 17 | 19 | With reply |

Installation instructions:

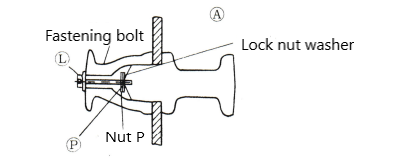

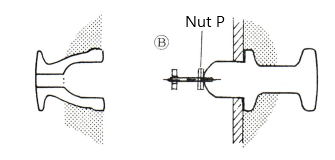

- Screw a bolt into the ‘male’ key, stand it up, and secure it with a lock nut washer and nut P as a precaution against loosening.

- Pass the ‘male’ key through the hole in the separator and crown it with the ‘female’ key.

- Since the other end of the bolt protrudes from the hole in the ‘female’ key, crown it with a plastic washer and then tighten it from the outside with a lock nut washer and nut L. (If the bolt is too long, please cut off the excess with pliers.) See Figure A.

- In this state, pour concrete and apply a vibrator, it will not loosen.

- When separating the blocks, the plastic washer in the ‘female’ key part will break, and the bolt will remain attached to the ‘male’ key. The keys will be separated, so loosen the fixed nut P and remove the bolt. See Figure B.

- If the bolt remains on the ‘female’ key side, slightly bend the bolt with radio pliers and then rotate the bolt to release it from the nut in the ‘female’ key part. See Figure.

- The PC blocks are shipped from the manufacturing site in the form shown in Figure ①.

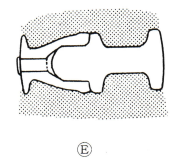

- At the site, they are joined as shown in the figure.

- Using a plastic washer makes it easier to handle, as the bolt will not remain in the ‘female’ key. It will not loosen even during concrete pouring, so you can use it with confidence.

Joint Key Test

- Test Purpose: The test was conducted to measure the endurance and displacement of the new joint key, to confirm its safety.

- Shape and Dimensions: The dimensions are as shown in the diagram below.

3. Test Method:

We applied epoxy resin to the joint surface in the same manner as fieldwork. We then applied a vertical load using an Amsler device within the usable time to generate displacement. We measured the amount of displacement using a 1/100 mm dial gauge..

Shear force = P/1.414

4. Test Results:

(1) The gap during the combination of male and female parts was 0.15 mm (difference in diameter of 0.3 mm), and the measured fit was 0.04 mm.

(2) This time, we conducted the test with a size of 32. We observed no abnormalities in the test body at the design endurance of 8T, and the displacement, including the fit, measured 0.25 mm.

At this time, the vertical stress was

n = 8000 / (30 x 20 x 1.414) = 9.4 kg/cm².

(3) The occurrence of cracks was observed at P=35T (shear force of 24.8T).

(4) The final load applied was up to P=50T (shear force of 35.4T), but it did not lead to failure.

Material list of round-shape type shear key for prestressed precast block

| Number | Name | Material | Quantity |

| 1 | Key (Male Type) | FCD 450 | 1 |

| 2 | Key (Female Type) | FCD 450 | 1 |

| 3 | Bolt/M5 Double cut | SS 400 | 1 |

| 4 | Nut and Spring Washer | 2 | |

| 5 | Seat Gold | Nylon Resin | 1 |

Round joint key material table for PC precast blocks

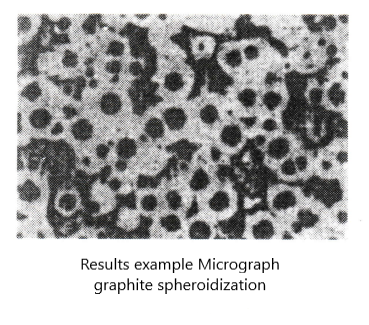

Test piece results (example) | ||||||||

| Test Piece | Material | Tensible test | Note | |||||

| Test piece Diameter (mm) | Gauge Length (mm) | Tensile Strength (N/mm²) | Yield Strength (N/mm²) | Elongation (%) | Cutting Point | |||

| (Standard) | FCD450 | 14 | 50 | More than 450 | More than 280 | More than 10 | ||

| 2536 | FCD450 | “ | “ | 477 | 321 | 24.8 | A | (JIS, cut from A-block) |

| 2544 | FCD450 | “ | “ | 480 | 333 | 22.3 | A | “ |