Nissan Tanaka

NISSAN TANAKA Low Spatter Adhesion Ozzle

Manufacturer: Nissan Tanaka

Product’s name: Low Spatter Adhesion Nozzle

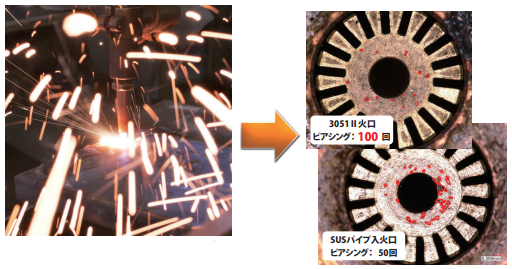

[Durability test by piercing]

One Point! What is a Diverging Nozzle!

– Correctly known as a Divergent Nozzle, it is a type of nozzle used for high-speed cutting with high oxygen cutting pressure.

– Structurally, it differs from a straight nozzle in that the oxygen cutting hole exit widens towards the end.

– This allows for the generation of supersonic oxygen cutting airflow, enabling high-speed cutting.

One Point! What is Concentrated Flame Type!

– The Concentrated Flame Type refers to a nozzle where the preheated gas flow path has a tapered shape.

– Its distinctive feature is that the preheated flame is concentrated at a single point.

– This enables the completion of preheating and piercing operations before cutting starts in a shorter time.

– Due to the concentration of the preheated flame, the setting and adjustment of the nozzle height become more crucial.

Advantages

– By changing the material of the internal nozzle, it suppresses an increase in surface roughness due to heating and reduces spatter adhesion.

– Significantly reduces maintenance frequency, thereby improving nozzle lifespan and operational efficiency.

– Environmental impact is reduced by extending nozzle lifespan and eliminating polyethylene bags for packaging.

– The 3057BBⅡ is designed for high concentration of preheating flame, allowing for quicker completion of piercing and preheating before cutting.

Nozzle Condition Table

| No | 3051Ⅱ nozzle for LPG | ||||||

| Cutting Thickness [mm] | Cutting Speed (※1) [mm/min] | Gas Pressure [MPa] | Gas Consumption [L/h(nor)] | ||||

| Oxygen | LPG | Cutting Oxygen | Preheating Oxygen | LPG | |||

| 0 | 6~9 | 600~530 | 0.3 | 0.02 | 1.1 | 1.1 | 300 |

| 1 | 9~16 | 530~450 | 0.35 | 0.02 | 2 | 1.3 | 350 |

| 2 | 16~32 | 450~400 | 0.35 | 0.02 | 0.1 | 1.3 | 350 |

| 3 | 32~40 | 400~350 | 0.35 | 0.03 | 5.1 | 1.3 | 350 |

| 4 | 40~60 | 350~250 | 0.45 | 0.04 | 8.5 | 1.5 | 400 |

| 5 | 60~100 | 250~150 | 0.5 | 0.04 | 12.5 | 1.5 | 400 |

| 6 | 100~170 | 150~100 | 0.55 | 0.05 | 16.5 | 1.85 | 500 |

| 7 | 170~250 | 100~80 | 0.55 | 0.05 | 23.5 | 3 | 800 |

| 8 | 250~300 | 80~70 | 0.55 | 0.05 | 28.5 | 3.35 | 900 |

| 9 | 300~350 | 70~45 | 0.6 | 0.05 | 36 | 3.65 | 800 |

| No | 3055Ⅱ Diverging Nozzle for LPG 5K | ||||||

| Cutting Thickness [mm] | Cutting Speed (※1) [mm/min] | Gas Pressure [MPa] | Gas Consumption [L/h(nor)] | ||||

| Oxygen | LPG | Cutting Oxygen | Preheating Oxygen | LPG | |||

| 0 | |||||||

| 1 | 9~16 | 640~540 | 0.5 | 0.02 | 2.4 | 1.12 | 300 |

| 2 | 16~32 | 540~470 | 0.5 | 0.025 | 3.6 | 1.3 | 350 |

| 3 | 32~40 | 470~420 | 0.5 | 0.025 | 4.8 | 1.3 | 350 |

| 4 | 40~50 | 420~350 | 0.5 | 0.03 | 5.6 | 1.85 | 500 |

| 5 | 50~100 | 350~250 | 0.5 | 0.03 | 8.8 | 1.85 | 500 |

| 6 | 100~150 | 250~175 | 0.5 | 0.03 | 13.5 | 3 | 800 |

| 7 | 150~250 | 175~90 | 0.5 | 0.04 | 24 | 3.65 | 980 |

| 8 | |||||||

| 9 | |||||||

| No | 3057Ⅱ Diverging Nozzle for 7K (※2)/ 3057BBⅡ Diverging Nozzle for 7K (Preheating Taper) | ||||||

| Cutting Thickness [mm] | Cutting Speed (※1) [mm/min] | Gas Pressure [MPa] | Gas Consumption [L/h(nor)] | ||||

| Oxygen | LPG | Cutting Oxygen | Preheating Oxygen | LPG | |||

| 0 | 6~9 | 740~700 | 0.7 | 0.02 | 1.1 | 1.12 | 300 |

| 1 | 9~16 | 700~600 | 0.7 | 0.02 | 2.5 | 1.12 | 300 |

| 2 | 16~32 | 600~500 | 0.7 | 0.025 | 3.8 | 1.3 | 350 |

| 3 | 32~40 | 500~450 | 0.7 | 0.025 | 5.4 | 1.3 | 350 |

| 4 | 40~50 | 450~400 | 0.7 | 0.03 | 7.3 | 1.85 | 500 |

| 5 | 50~100 | 400~250 | 0.7 | 0.03 | 10 | 1.85 | 500 |

| 6 | 100~150 | 250~180 | 0.7 | 0.03 | 14 | 3 | 800 |

| 7 | 150~250 | 180~100 | 0.7 | 0.04 | 22 | 3.65 | 980 |

| 8 | 250~300 | 100~70 | 0.7 | 0.04 | 35 | 3.65 | 980 |

| 9 | |||||||

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka

Related Products

-

NISSAN TANAKA 113Z, 513Z Cutting Torch Z (B Type)

-

NISSAN TANAKA 0MC Series Analytical Pressure Regulators

-

NISSAN TANAKA KT-160NII, KT-160NII (Circle Option) Oxy-Fuel Gas Portable Free Line Cutting Machine

-

NISSAN TANAKA AU150B-H12 Ⅱ Pressure Regulator For Other Applications

-

NISSAN TANAKA Weld Monitoring Camera

-

NISSAN TANAKA COMET(CMH Series) Industrial Pressure Regulator