Akashin Corporation

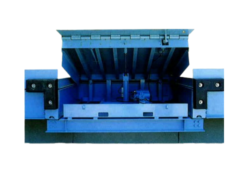

Akashin Alpha Series Accurate Mechanism Low-Cost and Low-Floor Electric Lift

Made In Japan

Manufacturer: Akashin Corporation

Model: Alpha Series

Feature

- Structure with less lateral shaking – This product can be used safely as it moves up and down horizontally via a pantograph arm (X-shaped arm).

- Compared to the chain type, it has a structure with no rattle – The electric motor holds the screw firmly at the stop position. There is no rattle like with the chain type, and it is always possible to perform stable lifting and lowering operations.

- Raises and lowers at a constant speed – The speed when going up and down is constant so that you can work efficiently.

- Can be maintained in the elevated state for a long time – Even if the table is left elevated for a long time, it can hold a constant height without naturally descending.

- Excellent stopping accuracy – Unique advanced functions achieve precise stopping accuracy (patent pending). Ideal for applications that require lift-stopping accuracy.

- Easy maintenance – Grease nipples are standard equipment, making lubrication easy and allowing for long-term, safe use.

- No oil leakage – There is almost no oil leakage or oil odor that is common with hydraulic lifts, keeping the work environment clean.

- Minimum height has been lowered by one step – The minimum height can be set lower, expanding the range of use more than ever before.

- Quiet when lifting – Compared to hydraulic lifts, the noise during lifting and lowering is extremely low, so there is no risk of scattering noise in the surrounding area.

- Continuous movement is possible (high frequency compatible) (300,000 times test cleared / α-0610-45-12 type) -Outstanding durability that easily clears the 300,000 times test. (However, this may vary slightly depending on the usage environment)

Application

Quiet, precise and clean, it can be used for a wide range of applications.

- Various conveyor lines

- Stage set

- Food factory production line

- Automobile factory production lines and assembly lines

- Automated Warehouse

- Chemical factory production line

- Working scaffolding

- Docking with the robot

- Various conveying lines

- Production and assembly lines in home appliance factories

Standard Specifications

| Operation | Two-point push button |

|---|---|

| Code | 3m |

| Standard paint color | Japan Paint 442 |

| Power supply | 3 phase 200V |

| Format | Load capacity | Lifting height | Table Dimensions | Minimum Height | Base Dimensions | Motor Capacity | Rise Time | Weight | |

|---|---|---|---|---|---|---|---|---|---|

| α-W×L-Head-Load | KG | S(mm) | W×L(mm) | H(mm) | W×L(mm) | KW | 50HZ | 60HZ | kg |

| α-0610- 45-06 | 600 | 450 | 640×1000 | 185 | 640×1000 | 0.4 | 16 | 15 | 260 |

| 0.75 | 10 | 9 | |||||||

| α-0810- 45-06 | 800×1000 | 0.4 | 16 | 15 | 275 | ||||

| 0.75 | 10 | 9 | |||||||

| α-1010- 45-06 | 1000×1000 | 1000×1000 | 0.4 | 16 | 15 | 285 | |||

| 0.75 | 10 | 8 | |||||||

| α-0612- 65-06 | 600 | 650 | 640×1200 | 185 | 640×1200 | 0.4 | 28 | twenty three | 275 |

| 0.75 | 17 | 14 | |||||||

| α-0812- 65-06 | 800×1200 | 0.4 | 28 | twenty three | 285 | ||||

| 0.75 | 17 | 14 | |||||||

| α-1012- 65-06 | 1000×1200 | 1000×1200 | 0.4 | 28 | twenty three | 305 | |||

| 0.75 | 17 | 14 | |||||||

| α-1212- 65-06 | 1200×1200 | 0.4 | 28 | twenty three | 345 | ||||

| 0.75 | 17 | 14 | |||||||

| α-0615- 80-06 | 600 | 800 | 640×1500 | 210 | 640×1500 | 0.4 | 33 | 27 | 310 |

| 0.75 | 20 | 17 | |||||||

| α-0815- 80-06 | 800×1500 | 0.4 | 33 | 27 | 325 | ||||

| 0.75 | 20 | 17 | |||||||

| α-1015- 80-06 | 1000×1500 | 1000×1500 | 0.4 | 33 | 27 | 340 | |||

| 0.75 | 20 | 17 | |||||||

| α-1215- 80-06 | 1200×1500 | 0.4 | 33 | 27 | 355 | ||||

| 0.75 | 20 | 17 | |||||||

| α-0618-100-06 | 600 | 1000 | 640×1800 | 210 | 640×1800 | 0.4 | 37 | 31 | 345 |

| 0.75 | 19 | 16 | |||||||

| α-0818-100-06 | 800×1800 | 0.4 | 37 | 31 | 365 | ||||

| 0.75 | 19 | 16 | |||||||

| α-1018-100-06 | 1000×1800 | 1000×1800 | 0.4 | 47 | 39 | 385 | |||

| 0.75 | twenty three | 19 | |||||||

| α-1218-100-06 | 1200×1800 | 0.4 | 47 | 39 | 395 | ||||

| 0.75 | twenty three | 19 | |||||||

| α-0610- 45-12 | 1200 | 450 | 640×1000 | 230 | 640×1000 | 0.75 | 15 | 12 | 345 |

| α-0810- 45-12 | 800×1000 | 800×1000 | 0.75 | 15 | 12 | 355 | |||

| 1.5 | 8 | 6 | |||||||

| α-1010- 45-12 | 1000×1000 | 1000×1000 | 0.75 | 15 | 12 | 370 | |||

| 1.5 | 8 | 6 | |||||||

| α-0612- 65-12 | 1200 | 650 | 640×1200 | 230 | 640×1200 | 0.75 | 26 | twenty two | 375 |

| α-0812- 65-12 | 800×1200 | 800×1200 | 0.75 | 26 | twenty two | 385 | |||

| 1.5 | 13 | 11 | |||||||

| α-1012- 65-12 | 1000×1200 | 1000×1200 | 0.75 | 26 | twenty two | 410 | |||

| 1.5 | 13 | 11 | |||||||

| α-1212- 65-12 | 1200×1200 | 0.75 | 26 | twenty two | 420 | ||||

| 1.5 | 13 | 11 | |||||||

| α-0615- 80-12 | 1200 | 800 | 640×1500 | 230 | 640×1500 | 0.75 | 31 | 26 | 425 |

| α-0815- 80-12 | 800×1500 | 800×1500 | 0.75 | 31 | 26 | 440 | |||

| 1.5 | 16 | 13 | |||||||

| α-1015- 80-12 | 1000×1500 | 1000×1500 | 0.75 | 31 | 26 | 455 | |||

| 1.5 | 16 | 13 | |||||||

| α-1215- 80-12 | 1200×1500 | 0.75 | 31 | 26 | 475 | ||||

| 1.5 | 16 | 13 | |||||||

| α-0618-100-12 | 1200 | 1000 | 640×1800 | 230 | 640×1800 | 0.75 | 38 | 32 | 465 |

| α-0818-100-12 | 800×1800 | 800×1800 | 0.75 | 38 | 32 | 485 | |||

| 1.5 | 19 | 16 | |||||||

| α-1018-100-12 | 1000×1800 | 1000×1800 | 0.75 | 38 | 32 | 510 | |||

| 1.5 | 19 | 16 | |||||||

| α-1218-100-12 | 1200×1800 | 0.75 | 38 | 32 | 525 | ||||

| 1.5 | 19 | 16 | |||||||

| α-1012- 65-20 | 2000 | 650 | 1000×1200 | 280 | 1000×1200 | 1.5 | 20 | 17 | 545 |

| α-1212- 65-20 | 1200×1200 | 1.5 | 20 | 17 | 565 | ||||

| α-1015- 80-20 | 800 | 1000×1500 | 280 | 1000×1500 | 1.5 | twenty five | twenty one | 615 | |

| α-1215- 80-20 | 1200×1500 | 1.5 | twenty five | twenty one | 640 | ||||

| α-1018-100-20 | 1000 | 1000×1800 | 300 | 1000×1800 | 1.5 | 32 | 27 | 680 | |

| α-1218-100-20 | 1200×1800 | 1.5 | 32 | 27 | 705 | ||||

*For continuous operation (within 3 minutes), please use at 80% of the load capacity. *All models in this catalog are designed for equal loads, so please contact us if you wish to use them with uneven loads.

We offer a wide range of options to enhance usability. Please choose the one that best suits your environment.

- Enlarging table dimensions – We can change the table dimensions according to your request.

- Foot switch – hands free and easy to operate.

- Four-sided bellows – Prevents foreign objects from getting caught in the lift body when the table is raised or lowered.

- Roll-up curtain – A screen that is attached to one side of a table.

- Anchor bracket – A bracket for fixing the main unit to the floor with anchor bolts.

Related Products

-

Akashin HE series Economy Type Transportation Support System Electric Dock Leveler

-

Akashin AK-04 High-altitude Work Vehicle Picking Lift

-

Akashin AD-21 Teachingless Surface Removal Machine

-

Akashin SW-11 Constant Pressure Swing Type Surface Removal Machine

-

Akashin ATP Series Right-Angle Direction Changer Pointer

-

Akashin HS Series Transportation Support System Electric Dock Leveler