Japan

Automatic Ultrasonic Inspection Equipment For Projection Welds

Made in Japan

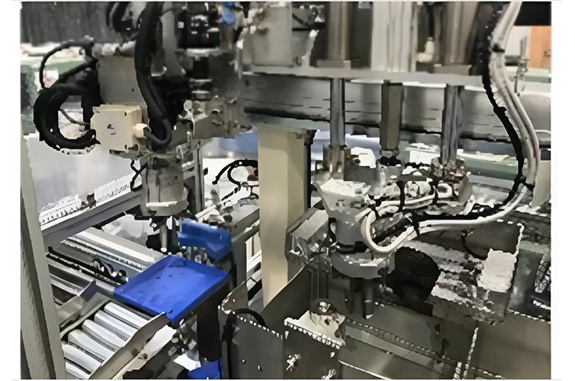

Product name: Automatic Ultrasonic Inspection Equipment For Projection Welds

Feature

- This equipment performs 100% inspection of projection welds of automobile parts using ultrasonic flaw detection.

- Judges the nugget diameter and joint status of the projection-welded part of the automatically transported workpiece without water immersion.

- This equipment laser marks inspected products after draining and transports them to the downstream process.

Specifications Automatic

| Item | Details |

|---|---|

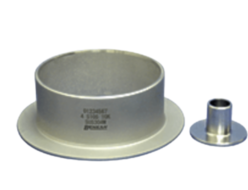

| Target work | |

| Shape | Circular part |

| Material | Fe-based |

| Dimensions, etc. | Φ200mm or less |

| Flaw detection method and inspection performance | |

| Flaw detection method | Local water immersion vertical flaw detection method |

| Target flaws | Nugget diameter, blowhole, joint pitch, etc. |

| Inspection performance | Measurement resolution of 0.1 mm or less |

| Processing capacity | 30 seconds/piece or less |