Nippon Avionics Co., Ltd.

Avio SW-D Series Ultrasonic Welding Machine

Manufacturer: Nippon Avionics Co., Ltd.

Model: SW-D Series

Features of SW-D Series

- Selectable Oscillation Mode

- Peak power control

- Energy control

- Timer control

- Continuous oscillation control

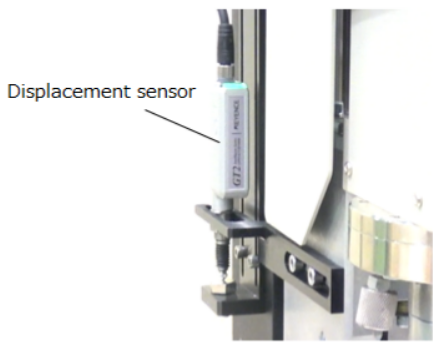

- External sensor control (Displacement sensor, Temp. sensor, etc.)

- Parameter setting

- Welding result display

- LCD touch panel

- Small size/ Light weight

- Detachable and to be used with multiple unit.

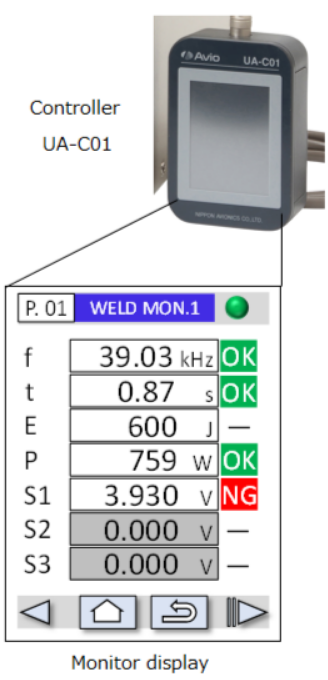

- Real-time Monitoring

- Peak power value

- Energy value

- Frequency

- Oscillation time

- External sensor value (3ch)

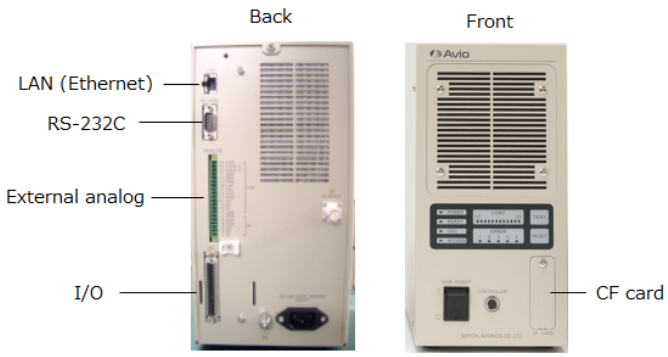

- Many Interfaces

- LAN(Ethernet)

- RS-232C

- Analog

- I/O

- CF Card

- More Convenient

- AC100-240V multi-power source

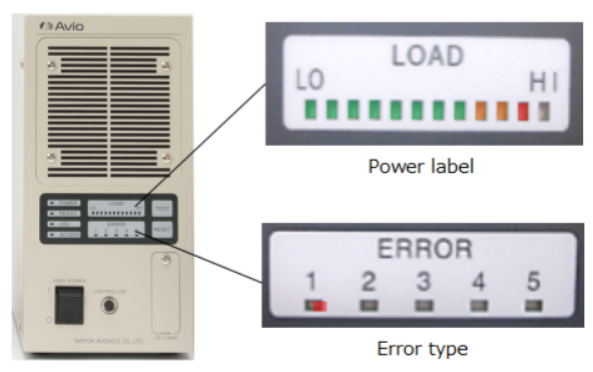

- LED error display

- Overcurrent protection, large ventilation fan

Ultrasonic Welding Machine Specifications

| Items | SW-D900S-20 | SW-D900S-27 | SW-D900S-39 | SW-D600S-39 | SW-D600S-48 |

|---|---|---|---|---|---|

| Max. Output Power | 900W (In continuous : 400W) | 600W (In continuous : 300W) | |||

| Frequency | 20kHz | 27kHz | 39kHz | 39kHz | 48.5kHz |

| Oscillation Method | Digital ATHMOS | ||||

| Amplitude Adjustment | 30~100% (1% step) | ||||

| Oscillation Control Mode | Time / Energy / Peak Power / External Sensor / Continuous | ||||

| Monitor Function (Pass / Fail Judgement) | Frequency / Oscillate Time / Energy / Peak Power / External Sensor | ||||

| Parameter Memory | 31 | ||||

| Interface | I/O / Analog / RS-232C / LAN / CF Card | ||||

| Input Power | Single Phase AC100~240V ±10% | ||||

| Power Consumption | 1,350VA | 900VA | |||

| Operating temperature | 5~50℃ (No freezing) | ||||

| Operating Humidity | Less than 90% (No condensation) | ||||

| Dimension | W150×D370×H310mm (Including protrusions) | ||||

| Weight | ≒ 8.5kg | ||||

Portable Controller Specifications

| Items | UA-C01 | |

|---|---|---|

| LCD | Size | 3.5 inch TFT LCD |

| Resolution | W320×H240 | |

| Color | 4,096 colors | |

| Touch Panel | Method | RESISTANCE FILM TYPE |

| Buzzer | available | |

| Language | English | |

| Power Input | Supplied From Welding | |

| Cable Length | 1.5m | |

Related Products

-

Avio CNT-320B Drive Unit For Resistance Welder

-

Avio High-End Model Small Size Ultrasonic Metal Welder

-

Avio N2 Gas Fully Automatic Parallel Seam Sealer

-

Avio NRW-IN400PA Resistance Welder Inverter

-

Avio Vacuum Fully Automatic Parallel Seam Sealer

-

Avio SW-D10KH-20/SH-H10K 10kW Ultrasonic Metal Welder For EV High Voltage Cables