BINZEL JAPAN Ltd

Binzel Japan SWR Spool Welding Robot

Manufacturer: BINZEL JAPAN Ltd

Model: SWR

Collaborative robots maximize productivity and performance

The spool welding robot SWR increases the productivity of pipe production plants and at the same time reduces the costs of pipe production. Efficient welding technology and statistical reports create a synergy that guarantees consistent quality. The collaborative welding robot maximizes productivity and space efficiency while reducing operating costs. Novarc Technologies and ABICOR BINZEL offer the SWR spool welding robot in an international collaboration.

Benefits at a glance:

You can perform continuous welding from the root to the cap.

The NovEye ® camera and NovData ® data acquisition system allow constant, clear monitoring of the process and its results.

It has an open platform format with a footprint of 1.2m x 1.2m, allowing the use of up to five positioners in a small space.

You can weld pipe spools using gas metal arc welding and metal cored arc welding.

Flux cored arc welding is an optional package.

They provide it as a mass production facility.

Overview of spool welding robot:

High technical expertise by ABICOR BINZEL

This spool welding robot offers a perfect combination with ABICOR BINZEL welding equipment for consistent quality and best results. In particular:

ABIROB ® W Torch

TH6D Seam Tracking

Master Liner

EWR2/EWR2Net as optional equipment

Top quality monitoring

The innovative NovEye ® camera and NovData ® software provide welders and other operators with clear and excellent monitoring for welding and welding parameter settings.

Welding performance (current value, heat input, moving speed, wire melting speed, etc.)

Welding during operation

Daily Driving Report

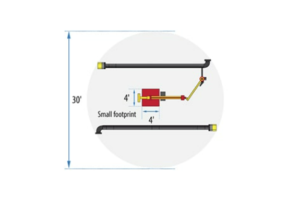

Small footprint

With a small footprint of 1.2m x 1.2m and a maximum range welding arm, the spool welding robot can be deployed in busy pipe manufacturing plants:

With a small footprint of 1.2m x 1.2m and a maximum range welding arm, the spool welding robot can be deployed in busy pipe manufacturing plants:

You can use up to five positioners.

The existing positioner can be used for SWR.

Easy to use

The operation method of the spool welding robot is designed for welding operators and supervisors. It can weld pipes from root to cap.

Even novice welding engineers and operators can operate it.

No special programming knowledge is required.

No heavy safety fences are required.

Simply connect, set and weld.