Chiyoda Tsusho, Japan

Chiyoda Tsusho Pulse Blowing Controller

Made in: Japan

Manufacturer: Chiyoda Tsusho

Forte

● Reduces air blow air consumption by about 50% The valve release and closing time are the same. With the same working time as conventional continuous blowing, air consumption can be reduced by 1/2.

● No power supply required (no electrical wiring required) The internal cylinder is operated only by the power of the primary air, and only by the air from the supply port.

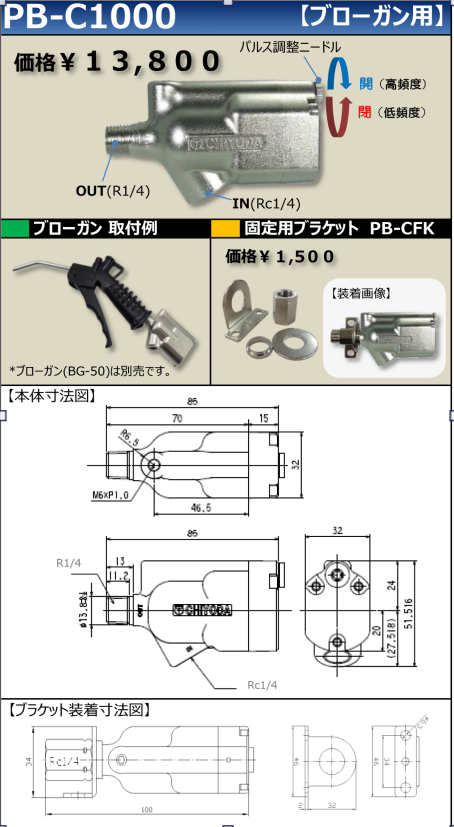

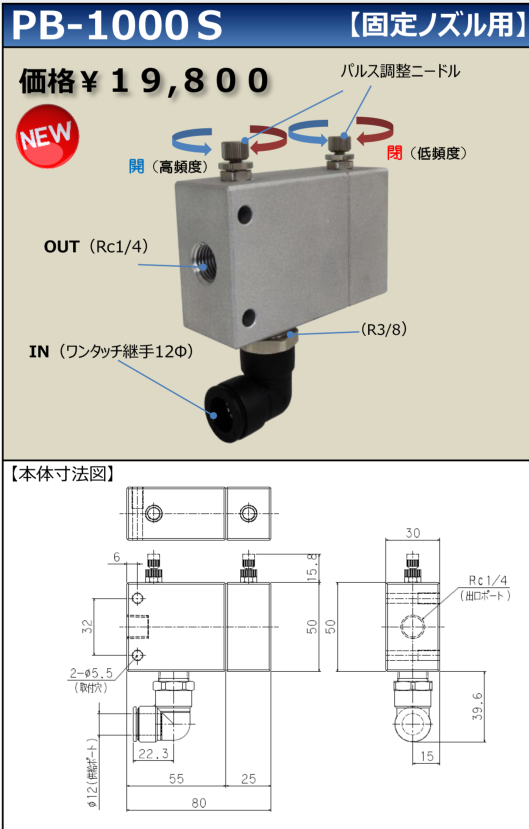

● Pulse adjustment is easy to adjust only the pulse adjustment valve, turn it to the right to low frequency (long pulse interval), turn it left to high frequency (pulse interval becomes faster).

Features of Pulse Blow

● Reduced air consumption for air blow by 1/2 Valve opening and closing times are the same. Air consumption can be reduced to 1/2 of his for the same working time as conventional continuous blowing.

● No power supply required

Only the air from the supply port (IN) operates the internal cylinder to generate pulses.

● Easy pulse adjustment

Only the pulse adjustment needle is adjusted, turned right for low frequency (longer pulse intervals) and left for high frequency (faster pulse intervals).

● Increased air blow effect

Objects such as chips can be efficiently removed by generating shock waves.

Specifications

| PB-C1000 | PB-1000S | |

| Working fluid | Compressed air | |

| Working pressure range | 0.3~1MPa | 0.3~0.7MPa |

| Operating temperature limit | 0~60°C | |

| Pulse control range | MAX 15 Hz | 2〜15Hz |

| Weight | 180g | 344g |

Performance comparison table

| PB-C1000 | PB-1000S | |

| Pulse adjustment | ◎ | Ο |

| Power | Ο | ◎ |

| Compact | ◎ | Ο |

| Blow gun mounting | Ο | - |

| Cost | ◎ | Ο |

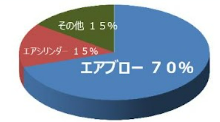

Air blow usage

Air blow is required when draining the water after processing in the processing factory.

Air blowers are said to account for about 70% of the air used in the entire factory.

About 50,000 yen of electricity is used per year for one air blower.

Related Products

-

Kyowa TP-2KCM TP-M High-speed Torque Transducer

-

Kyowa TE-55 P12-7×3 – ST40X-18S-CV1(80) Cable

-

Hammer Caster 502BPS-CU Big Size Urethane Thermosetting Wheel

-

Meiko Engineering JA Expansion Joint

-

TSURUMI PUMP PARTS: SHAFT SLEEVE Parts & Accessories

-

SAKUSAKU SDHR61925C2 Internal Coolant Holder For Internal Grooving