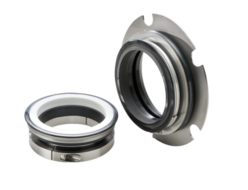

DGS Tandem Seal

This seal is used where small product leakages of process gas are acceptable, such as in gas pipeline compressors. It functions as a safety seal on the atmosphere side. The tandem arrangement ensures a high degree of operational safety. The seals on both the product and atmosphere sides can withstand the full pressure. Under normal operating conditions, the seal on the product side absorbs the full pressure. The space between the product-side seal and the atmosphere-side seal connects to the primary vent (flare) through a connection “B”. The pressure sealed by the atmosphere-side seal matches the primary vent pressure, resulting in minimal leakage to the secondary vent (atmosphere). If the main seal fails, the second seal serves as a safety backup.

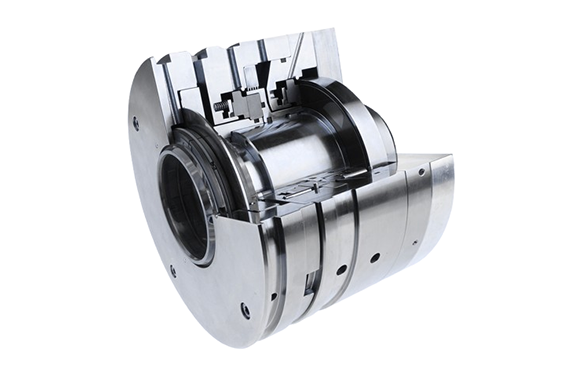

DGS Tandem Seal with Intermediate Labyrinth

This seal is used where product leakages to the atmosphere and nitrogen leakages from a dual seal to the product are unacceptable, such as in H2, ethylene, or propylene compressors. In this arrangement, the primary seal on the product side reduces the pressure, and all process gas leakage is discharged through connection “B” to the primary vent. The atmospheric side seal is supplied with secondary seal gas (nitrogen) via connection “C”. The pressure of the secondary seal gas ensures that nitrogen flows through the labyrinth and into the primary vent connection “B” along with the entire process gas leakage.

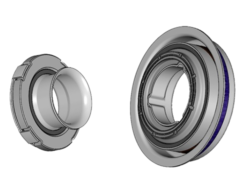

DGS Dual Seal

This seal is used when product leakages to the atmosphere are not permissible, and tandem arrangements are unsuitable due to low product gas pressures. Buffer gas leakages into the product are acceptable (buffer pressure p3 > p1). This seal is applied when a neutral buffer gas, at an appropriate pressure, is available. It is commonly used in the chemical industry, such as in HC gas compressors. Buffer gas, typically nitrogen, is supplied between the seals via connection “C” at a higher pressure than the product pressure. Part of the buffer gas leakage escapes to the atmosphere side, while the remaining part leaks into the product.