EIKOH, Japan

EIKOH Hexavalent Chromium Remover

Made in Japan

Manufacturer: Eikoh Co., Ltd.

New Product Announcement

Thank you for using our hexavalent chromium removal agent. Previously, GL-AO-C6R-I35 effectively treated finished leather, mainly used in leather product factories for post-processing. However, being a liquid, it incurred high transportation costs, raising the product cost. Additionally, it was difficult to use in the leather manufacturing process (pre-processing).

Through intensive development, we have launched a new product that solves all these issues.

New product name

GL-AO-C6R-N2 Series

Model number

For front-end process: GL-AO-C6R-N2(B) for 50L/100L

For back-end process: GL-AO-C6R-N2(A) for 1L/10L

*This product is a new technology announced at the Japan Horological Society on September 15, 2017.

How to use

For front-end process AO-C6R-N2(B): Powder type

Preparation of processing solution

Add 0.3 to 1.1 wt% of AO-C6R-N2(B) to the dry weight of the leather during finishing after dyeing and fat-liquidizing, and then dry.

When putting the leather into the drum, it is effective to use warm water of about 40°C to make the agent more easily soluble.

For N2(B), add this product to the drum after dyeing and fat-removing processes.

The recommended amount to add is 0.3 to 1.1% of the weight of dry leather. However, if the concentration of the treatment agent in the water is less than 1.1%, use 1.1%.

(A small amount of treatment agent in a large amount of water will not be effective enough. To dissolve the agent easily, raise the water temperature to around 40°C to speed up the process, but do not raise it above 70°C.)

For post-processing AO-C6R-N2(A): Powder type

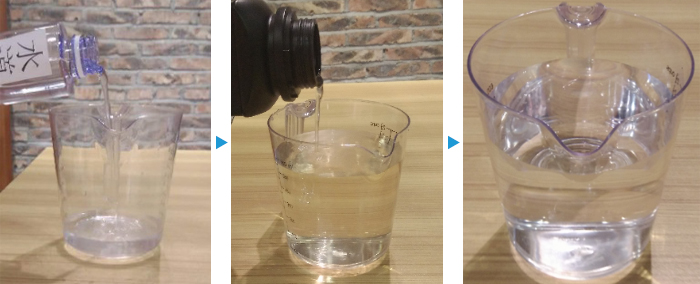

Preparation of processing solution

Make a mixture of 600mL water + 400mL IPA.

Add one bag of AO-C6R-N2(A) for 1L, dissolve, and it’s done.

How to use

AO-C6R-N2(A) (Used in the same way as the conventional I35.)

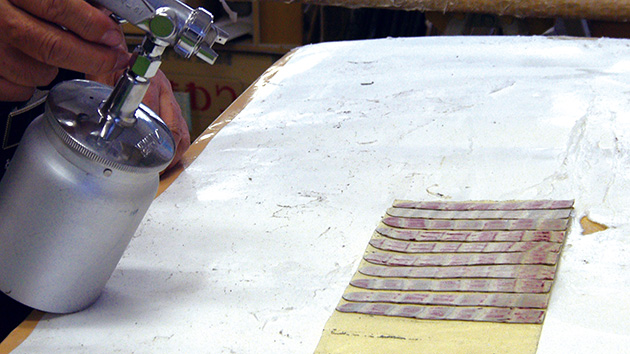

Processing method

Fill a spray bottle. (You can also apply it by brush or by dipping.)

Just apply it to a cloth, let it dry and you’re done.

Hexavalent chromium removal agent proposed by Eiko

Many leather products in the world are chrome-tanned.

This chrome tanning process uses trivalent chromium , but it has been discovered that this treated leather turns into hexavalent chromium

when exposed to sunlight, ultraviolet rays, and temperature. In Europe, restrictions have been put on products that contain hexavalent chromium , and products that contain hexavalent chromium can no longer be exported. (European REACH Regulation Annex XVII Entry 47*1)

The remover we recommend is a product developed by Citizen Watch Co., Ltd. to comply with European regulations.

*1 As of May 2015, leather parts that may come into contact with the skin and contain 3 ppm or more of hexavalent chromium can no longer be placed on the market.

Major features of the hexavalent chromium remover developed by Citizen Watch Co., Ltd.

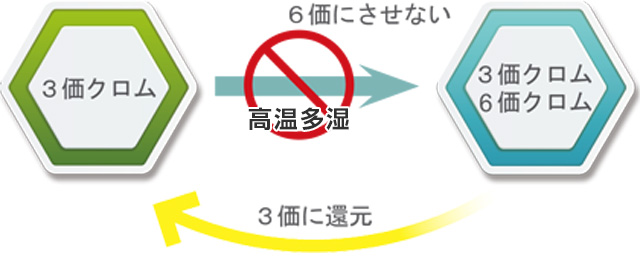

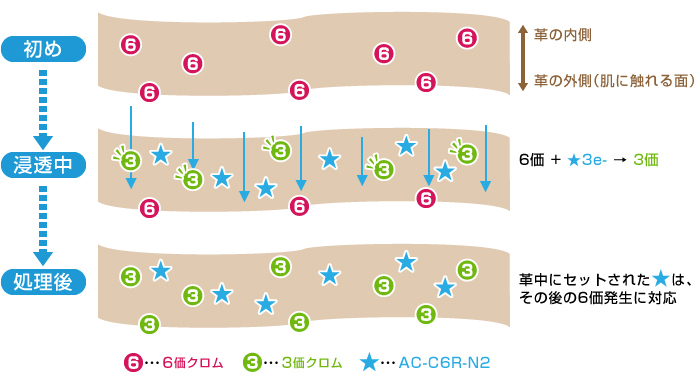

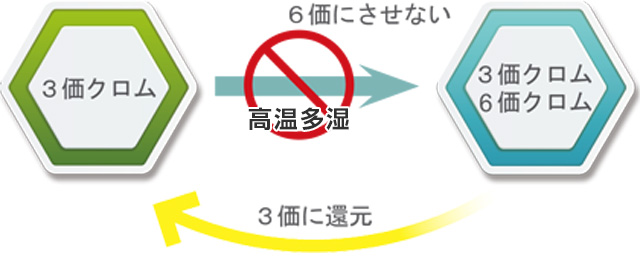

- 1. Reverting hexavalent chromium to trivalent chromium (reduction action)

- 2. Prevents trivalent chromium from becoming hexavalent chromium (antioxidation)

- 3. The above effects are maintained for a long period of time. (It has been adopted for leather bands by Citizen Watch Co., Ltd., and the long-term effect has been proven.)

Chrome and tanning

“Tanning” is the process of processing animal skin to obtain leather. Tanning can be done using either tannin or trivalent chromium, but most products are tanned with chromium because it produces high-quality leather that is heat-resistant and elastic. Products tanned with trivalent chromium are

harmless and safe immediately after processing, but over time, the trivalent chromium in the product changes to hexavalent chromium due to exposure to ultraviolet rays and temperature changes.

The generation of hexavalent chromium and the current state of leather

The table on the bottom right shows the measured chromium content of the product.

Measurement results for chrome-tanned leather products

| Product name | Total Chromium | Hexavalent chromium content |

|---|---|---|

| Product A | 16362 ppm | 3 ppm |

| Product B | 12598 ppm | Below detection limit |

| Product C | 10080ppm | Below detection limit |

| Product D | 9481 ppm | Below detection limit |

| Product E | 7141 ppm | 8 ppm |

Hexavalent chromium was detected in leather that should only contain trivalent chromium. Moreover, the leather with the smallest total amount of chromium contained the most?

Measurement method: Measured according to the REACH-specified measurement method (ISO17075)

Measurement organization: SGS Singapore (certified organization)

Unit explanation: ppm = concentration of 1 mg (about 1 earpick?) in 1 kg. 1000 mg = 1 g

⇒Hexavalent chromium is produced unknowingly depending on the storage environment before the product is sold.

Mechanism of formation of hexavalent chromium

Trivalent chromium can change into hexavalent chromium when exposed to heat, light, humidity, etc.

When leather is exposed to conditions that favor oxidation, trivalent chromium changes into hexavalent chromium.

⇒Even if it is confirmed that a product does not contain hexavalent chromium immediately after production, it may later unintentionally contain hexavalent chromium.

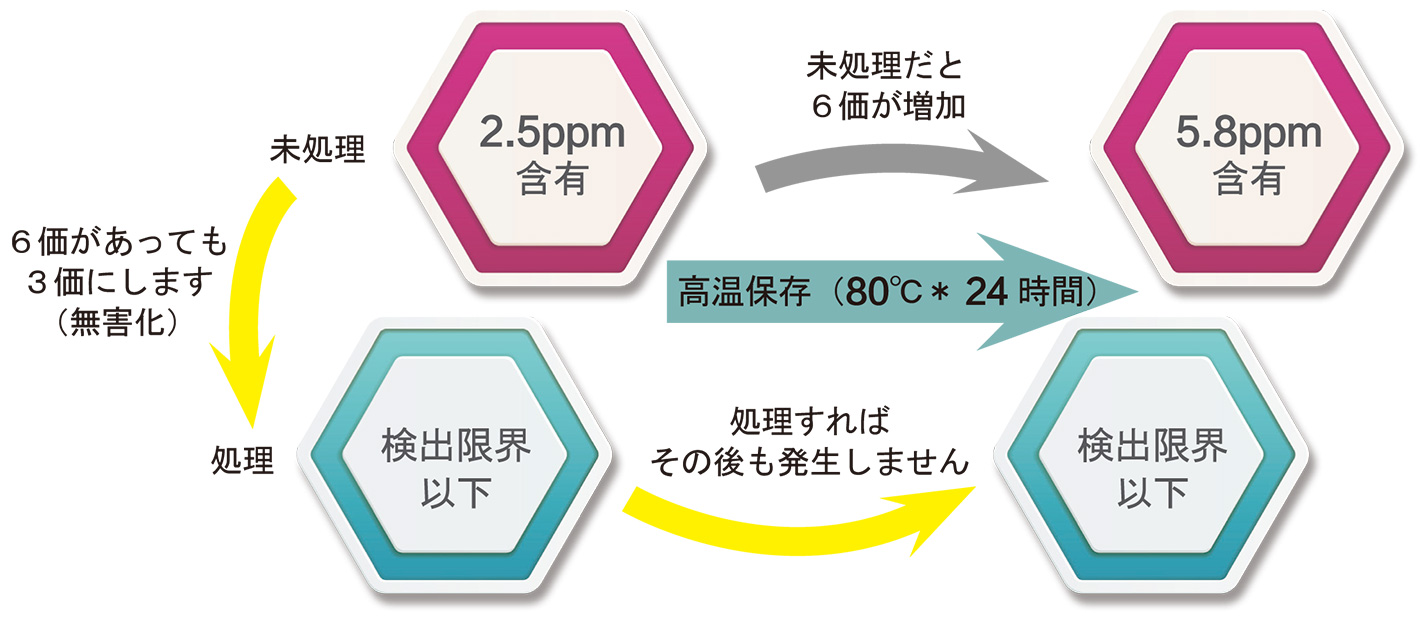

Changes in leather during processing (image)

In addition, please read the instruction manual before using this product.

Regarding hexavalent chromium regulations

The EU REACH Annex XVII restriction on hexavalent chromium in leather products that come into contact with the skin prohibits the inclusion of 3 ppm or more, and came into force on May 1, 2015.

For example, leather band products for Europe are subject to this restriction. Products that contain leather parts that may come into contact with the skin and whose leather parts contain 3 mg/kg (0.0003% by weight, 3 ppm) or more of hexavalent chromium in a dry state must not be placed on the market.

Penalties are based on the laws of the regulated countries.

Transition from ROHS to REACH

| European Regulations | Hexavalent chromium regulations | Measuring method | Differences in measurement methods |

|---|---|---|---|

| ROHS Directive | 1000ppm | IEC62321:2008 | 95 degrees for 3 hours |

| REACH Regulation | 3 ppm | ISO17075 | Room temperature for 3 hours |

European REACH Regulation Annex XVII Entry 47 will come into force on May 1, 2015

Regulatory Compliance (Hexavalent Chromium) Solutions

By applying the GL-AO-C6R series to leather, you can obtain leather that complies with regulations.

The GL-AO-C6R series has the function of returning the generated hexavalent chromium back to trivalent chromium (reduction), and can inhibit the conversion of the residual components of this product remaining in the leather from trivalent chromium to hexavalent chromium.

Application method

Apply the product from the back with a spray bottle. Of course, you can also immerse the product in water. It will be even more effective if you also treat the front side of the product.

Checking the effect

Crocodile skin example

If treated with this agent, no hexavalent chromium will be produced.

Confirmed using crocodile leather that had already generated hexavalent chromium during storage.

The above values are the hexavalent chromium content measured according to ISO17075.

Q&A

- What is the form?

- It is a powder packaged in an aluminum pouch.

- What water is used?

- City water can also be used. However, using pure water will be more effective as it contains fewer impurities.

- What about storage?

- Store in a location that is not exposed to direct sunlight, high humidity, or high temperatures.

- time limit?

- It will last for one year if unopened, but please use it within the same day after opening.

- Can I purchase from overseas factories?

- This is possible in some countries, so please contact us for details.

- Is it safe?

- Many watch bands have been used since 2014, and there have been no reported issues, but we cannot guarantee that all of them will work.

- What is the effect on leather?

- We cannot guarantee that it will work on all types of leather, but it can be used on many types of leather. Please check the effects of the product before use.

- Can the leather be treated from the surface?

- Do not use on white, yellow, or leather with a resin layer on the surface.

Related Products

-

Daitoukeiki WF12B type guage WF Enclosed Guages(Resin)

-

Gentos Flash Series (White Box Version) FLP-2106 Twist Focus Control Flashlight

-

TONE HSCL306 Deep Nut Hold Socket Set (With Socket Holder)

-

Kitz 600UMC,600UMCM Stainless & High Alloy Class 600 Gate Valve

-

Tokyo Sokushin VSE-315D6 Servo Velocity-meter

-

Gentos GH-103RG Headlight