ELEPHANT (Zojirushi), Geared Trolley, Lifting

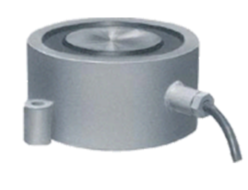

ELEPHANT (Zojirushi) Geared Trolley (Washer Type)

Product Made in Japan

Manufacturer: ELEPHANT CHAIN BLOCK CO., LTD. (Zojirushi)

Model Geared Trolley: G-0.5; G-1; G-1.6; G-2; G-3.1; G-5; G-7.5; G-10; G-16; G-20

Features

- To any beam width

Elephant adjustable trolleys are adjustable to any beam width, in three stages, simply by increasing or decreasing the number of the adjusting collars. - For both I-beam and H-beam

The wheels of the trolley fit both I-beam and H-beam. - High-quality closed bearings

High-quality closed bearings employed in the trolley provide smooth wheel travelling.

Specification

| Model | G-0.5 | G-1 | G-1.6 | G-2 |

| Capacity (ton) | 0.5 | 1 | 1.6 | 2 |

| Hand chain Dia. x pitch (mm)x(mm) |

5×22.5 | 6×26.6 | 6×26.6 | 6×26.6 |

| I-beam width (mm) | 58-130 | 58-130 | 70-155 | 70-155 |

| Trolley min. radius (mm) | 900 | 1100 | 1200 | 1200 |

| Net weight (kg) | 12.0 | 16.0 | 24.5 | 25.0 |

| Model | G-3.1 | G-5 | G-7.5 | G-10 |

| Capacity (ton) | 3.1 | 5 | 7.5 | 10 |

| Hand chain Dia. x pitch (mm)x(mm) |

6×26.6 | 6×26.6 | 5×23.6 | 5×23.6 |

| I-beam width (mm) | 90-160 | 90-180 | 125-190 | 125-190 |

| Trolley min. radius (mm) | 1700 | 2300 | *3000 | *3000 |

| Net weight (kg) | 33.5 | 55.8 | 107.0 | 117.0 |

*Minimum radius 3000mm of G-7.5 and G-10 is applicable for beam width 150-190mm only.

| Model | G-16 | G-20 |

| Capacity (ton) | 16 | 20 |

| Hand chain Dia. x pitch (mm)x(mm) |

5×23.6 | 5×23.6 |

| I-beam width (mm) | 150-190 | 150-190 |

| Trolley min. radius (mm) | 6000 | 6000 |

| Net weight (kg) | 315.0 | 420.0 |

Geared Trolley Dimensions

| Model | A | B | C | D | E | H | I | J |

| G-0.5 | 228.4 | 130.5 | 113 | 212 | 70 | 108 | 38 | 28 |

| G-1 | 250 | 130.5 | 117 | 236 | 80 | 112 | 40 | 30 |

| G-1.6 | 308 | 155.5 | 123 | 306 | 98 | 150 | 60 | 40 |

| G-2 | 308 | 155.5 | 123 | 306 | 98 | 150 | 60 | 40 |

| G-3.1 | 326 | 153 | 133.5 | 343 | 115 | 177.5 | 65 | 50 |

| G-5 | 367.2 | 183.5 | 160 | 406.5 | 125 | 222.5 | 80 | 60 |

| G-7.5 | 470 | 187 | 287 | 458 | 158 | 246 | 100 | 80 |

| G-10 | 470 | 187 | 287 | 458 | 158 | 246 | 100 | 80 |

| G-16 | 669 | 230.5 | 454.5 | 623 | 197 | 271.5 | φ60 | – |

| G-20 | 669 | 230.5 | 454.5 | 623 | 197 | 271.5 | φ60 | – |

The models higher than G-7.5 are slightly different from this drawing in shape.

1) Dimensions B and C are in the case of the minimum I-beam width.

2) Dimension H fluctuates to some degree depending on the width of the I-beam.