Exen, Vibration motor

EXEN ADS Automatic Operation Electric Distribution Box

Products Made In Japan

Manufacturer: EXEN

Model: ADS

Features

Exen has developed an Automatic Drive System (ADS), a system for automatically running a vibrator by using your own high-frequency vibrator power supply.

The system for automatic operation consists of a box for processing startup stop signals (ADS) and a signal-sensing vibrator (ADV).

There is one model with its box being an ADS.

There are two models with their vibrators being 40 mm in diameter with ADV 40 VA (6M) and 50 mm in diameter with ADV 50 VA (6M) for architectural and civil engineering purposes.

The vibrating body of the vibrator vibrates while in contact with freshly mixed concrete. This relieves the worker of the trouble of turning on and off the switch, thereby saving labor. Moreover, the vibrator does not run idle, which used to occur when moving to another concreting point or waiting for another batch of concrete to be poured. This makes it hard for the vibrating body of the vibrator automatic operation system to heat up. It is thus energy-saving and efficient.

It vibrates when it senses freshly mixed concrete and is easy to operate

The ADS begins to vibrate when its vibrating body enters into contact with freshly mixed concrete and stops vibrating when its vibrating unit is pulled out of the concrete.

This simplifies switch operation and makes it hard for the vibrating body of this internal vibrator to heat up and easy to operate in concreting.

Compatible with your existing high-frequency power supply

The high-frequency power for the ADS automatic operation system can be supplied with the 48 V series power supply inverter series or generator series that you may already have.

Composition of the automatic operation system (ADS)

The composition of the automatic operation system is used as connected to the box (ADS) that senses the contact of the ADV with concrete between the high-frequency power supply and the special-purpose high-frequency internal vibrator (ADV).

The system vibrates while the ADV is in contact with concrete and stops vibrating when pulled out.

Auto/manual operation switchover A

To set the ADS special-purpose vibrator (ADV) to manual mode (by turning on and off the switch at hand), you can install an optional conversion cord (4P-EP30) to the vibrator and connect it directly to a high-frequency power supply.

Use it should your ADS malfunction or when you need to check your ADV for failure.

Connectable directly to the HC/HAG series by using a conversion cord assembly

Safe automatic operation

The voltage sensitivity of the automatic operation system is set to low, which is unlikely to cause electric shocks.

This enables safe concreting.

Energy-saving, efficient vibrator oriented toward a next generation

The automatic operation system (ADS) starts or stops when it senses the contact of the vibrating body of the vibrator with freshly mixed concrete.

The vibrating unit therefore does not run idle, which used to be seen with conventional vibrators, when concrete is poured. The vibrating body does not readily heat up, thereby refraining from wasting energy. As a result, concreting can be efficiently performed, resulting in conserving energy on worksites.

When you pull the vibrator out of the freshly mixed concrete, the vibrating body stops vibrating the moment the vibrating body leaves the concrete. When, therefore, pulling it out, you will stop feeling the vibration in your hand holding the hose, resulting in reduced fatigue and safer concreting.

Test run for automatic operation

Before concreting, be sure to check that the automatic operation system (ADS) runs problem-free.

*You can do this check with the vibrator (ADV) turned off.

1)Checking the vibrator

After installing the automatic operation system (ADS), turn on the high-frequency power.

Check that the ADS power lamp (green) goes on, then put the sensor clip of the ADS in contact with the vibrating unit of the vibrator (ADV).

If, when in contact, the ADS output lamp is on in red, then it can be automatically run.

*At that time, you can do the check with the vibrator (ADV) power off. If it is on, you can also check the vibration status of the vibrator.

2)On-site check before concreting

Install the automatic operation system (ADS), then turn on the high-frequency power.

Check that the ADS power lamp (green) is on, then install the sensor clip of the ASD on an electrically conductive rebar or cord mold close to the concreting site.

After that, put the vibrating body of the vibrator in contact with a rebar or cord on the site of concreting.

If, when in contact, the ADS output lamp is on in red, then it can be automatically run.

*At that time, you can run the check with the vibrator (ADV) power off. If it is on, you can also check the vibration status of the vibrator.

Test run procedure

Safe work! Ensure that every time you leave, turn off the power and switch

Basically, if the vibrator is not in a state to sense the sensor, it does not begin to run automatically. For an intermission or otherwise, to avoid malfunctioning, when you leave the vibrator, always ensure that you turn off the intermediate switch of the ADV vibrator and the inverter power of the power supply.

Specification

| Model | Input Voltage (V) |

Output current (A) |

Nos.of output socket outlet |

Weight (kg) |

|---|---|---|---|---|

| ADS | 48 | 3 | 2 | 6.75 |

(Imperial System)

| Model | Input Voltage (V) |

Output current (A) |

Nos.of output socket outlet |

Weight (lb) |

|---|---|---|---|---|

| ADS | 48 | 3 | 2 | 14.9 |

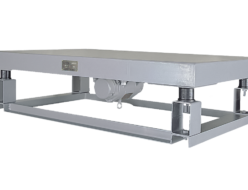

Dimensions, installation, control panel

Product dimensional drawings