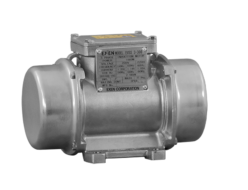

Exen, Pneumatic Vibrator

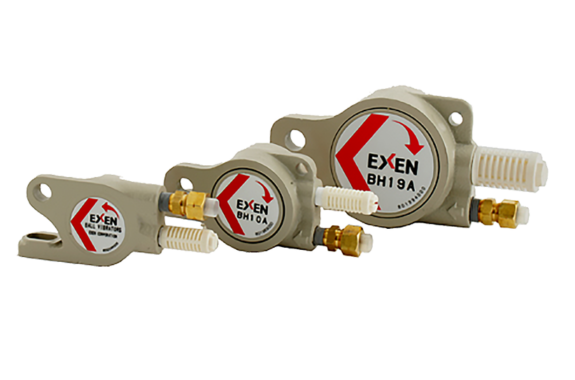

EXEN BH10A Ball Vibrator

Products Made In Japan

Manufacturer: EXEN

Model: BH10A

Compact pneumatic vibrator in a wide range of models and expanded applications

This product is used for the following applications:

- 01.Milling plant: installation to small screening machine made by user

- 02.Prevention of blockage in sodium chloride conveyance chute

- 03.Improvement of buildup of workpiece ejected in screw production line. Improvement of buildup of cutting workpiece ejected. Improvement of resin moulding cutout workpiece ejected

Features

Ball vibrator is a compact vibrator that generates powerful centrifugal force vibration via high-speed rotation of steel ball by compressed air. This vibrator has simple principle and structure and can be used easily. It is generally used for preventing clogging in hopper chute, but the applications are expanded depending on ideas. Frequency and centrifugal force can be freely changed only by operation of air pressure. Depending on the on-site installation conditions, selection can be made from model lineup of BH-A, CH-A, and UH-A, which are different in positions of air supply and exhaust. (Supplying lubricant with an oiler is required)

Simple vibrational principle with less failure

Having a principle that high-speed rotation of steel ball by supplied air generates vibration, ball vibrator has no complicated parts and is rarely failed.

Vibration force adjustable by pressure regulation of supply air

Simply operating the pressure of compressed air allows frequency and centrifugal force to be easily changed. Once the product is installed to a target object, it is possible to easily make the most appropriate adjustment of vibration, for example, by increasing the air setting pressure if the vibration is low or decreasing it if the vibration is high.

Easy maintenance

Ball can be replaced in all models. Replacement maintenance can be easily conducted by loosening bolts on the side cover, removing the side cover, and the replacing the ball. (Note: If the internal raceway ring is significantly worn, only replacing the ball will not repair the product)

Applications expanded on your idea

Although the ball vibrator is generally used to prevent minor clogging of powder in hopper or chute, it can be utilized as a motor for vibration table used for filling. Applications are expanded on various ideas, such as applying the vibration to eliminate buildup in parts supply line of production lines.

Model selection depending on on-site installation conditions

If there is a restriction on the pulling-out direction of supply air tube owing to the installation conditions, the model can be selected depending on the site, such as model UH for which air is supplied from upper side of body or model CH for which air is supplied from lateral side of body. If the product can be installed with only one bolt, model BH is available, which is installed with one bolt.

Complete airtight waterproof structure

Because ball vibrator is of waterproof structure, it can be used even in wet location. If hoses for air intake and exhaust are extended, it can transmit vibration to an object in water.

(Note that vibration efficiency decreases if the hose for air exhaust is extended.)Mounting holes for safety wire are provided as standard

All models of ball vibrator are provided with mounting holes for the fall prevention wire. It is highly recommended to mount the wire to ensure the safety in plant.(Wire is optional)

Lightweight and compact

The smallest model BH8 is a compact body in 18mm in installation width and 0.3kg in weight. Therefore, it can be installed to hopper or a small area to which standard vibrato cannot be installed. (Model BH can be installed in two direction). Pneumatic ball vibrator models UH, CH, and BH with steel body can select various directions of air supply and exhaust, and therefore, the model can be selected depending on the installation conditions. It can be also used in water because of its high airtightness. (Assuming that exhaust pipe is extended to the atmosphere)

Specification

BH/CH/UH

Model Required

to start

(MPa)Frequency(Hz)・Centrifugal Force(kN) Weight

(kg)0.2MPa 0.6MPa Vert. Horz. Hz kN m3/min

(ANR)Hz kN m3/min

(ANR)BH8 0.02 0.01 322 0.09 0.04 499 0.22 0.10 0.3 BH10A 0.03 285 0.13 0.07 451 0.33 0.17 0.5 BH19A 0.06 0.02 174 0.60 0.14 259 1.33 0.37 1.1 CH19A 162 0.52 0.13 240 1.15 0.35 1.2 CH25A 0.11 110 0.79 0.17 164 1.76 0.43 2.6 CH32A 0.20 – – – 137 2.11 0.40 2.4 UH13A 0.03 0.01 264 0.30 0.11 383 0.63 0.28 0.7 UH19A 0.06 0.02 163 0.53 0.13 246 1.2 0.34 1.2 UH25A 0.13 110 0.67 0.11 162 1.46 0.28 1.9 (Imperial System)

Model Required

to start

(PSI)Frequency(Hz)・Centrifugal Force(kN) Weight

(lb)29PSI 87 PSI Vert. Horz. VPM lbf CFM VPM lbf CFM BH8 2.90 1.45 19,320 20.2 1.4 29,940 49.5 3.5 0.7 BH10A 4.35 17,100 29.2 2.5 27,060 74.2 6.0 1.1 BH19A 8.70 2.90 10,440 134.9 4.9 15,540 299.0 13.1 2.4 CH19A 9,720 116.9 4.6 14,400 258.5 12.4 2.6 CH25A 15.95 6,600 177.6 6.0 9,840 395.7 15.2 5.7 CH32A 29.0 – – – 8,220 474.3 14.1 5.3 UH13A 4.35 1.45 15,840 67.4 3.9 22,980 141.6 9.9 1.5 UH19A 8.70 2.90 9,780 119.1 4.6 14,760 269.8 12.0 2.6 UH25A 18.85 6,600 150.6 3.9 9,720 328.2 9.9 4.2 *Use the product in ambient temperature of 80°C or more.

*The above specification is the result under measurement condition of EXEN. The actual data may differ from the above specification depending on the installation conditions.

*Pressure required to start may become higher than motion pressure, because the former pressure is a pressure when starting up with the pressure gradually risen at a position 3cm before the vibrator.

* Vertical indicates a direction in which a boll rotates vertically, and Horizontal indicates the result of installation with a boll rotates in planar direction. If the installation angle is other than vertical, starting pressure shows a lower trend than vertical.Dimensions, installation, control panel

Product dimensional drawings

Product dimensional table

Model L L1 H H1 W t t1 P P1 P2 φd φE G Tube Size BH10A 80 (109) 30 51 30 7 7 11 19 19 2-9

(M8)7 1/8 φ8×φ6

(mm)BH19A 110 (148) 40 70 37 14 11 14 24 27 2-11.2

(M10)1/4 (Imperial System)

Model L L1 H H1 W t t1 P P1 P2 φd φE G Tube Size BH10A 3,1 (4.3) 1.2 2 1.2 0.3 0.3 0.4 0.7 0.7 2-5/16

(M8)0.3 1/8 φ8×φ6

(mm)BH19A 4.3 (5.8) 1.6 2.8 1.5 0.6 0.4 0.6 0.9 1.1 2-7/16

(M10)1/4